Low-yield single-pump two-stage reverse osmosis system

A two-stage reverse osmosis and reverse osmosis technology, applied in reverse osmosis, osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of long-term stability of water quality, low recycling rate, and economic benefits No obvious problems, etc., to achieve stable and rapid water quality, improve water quality, and reduce consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

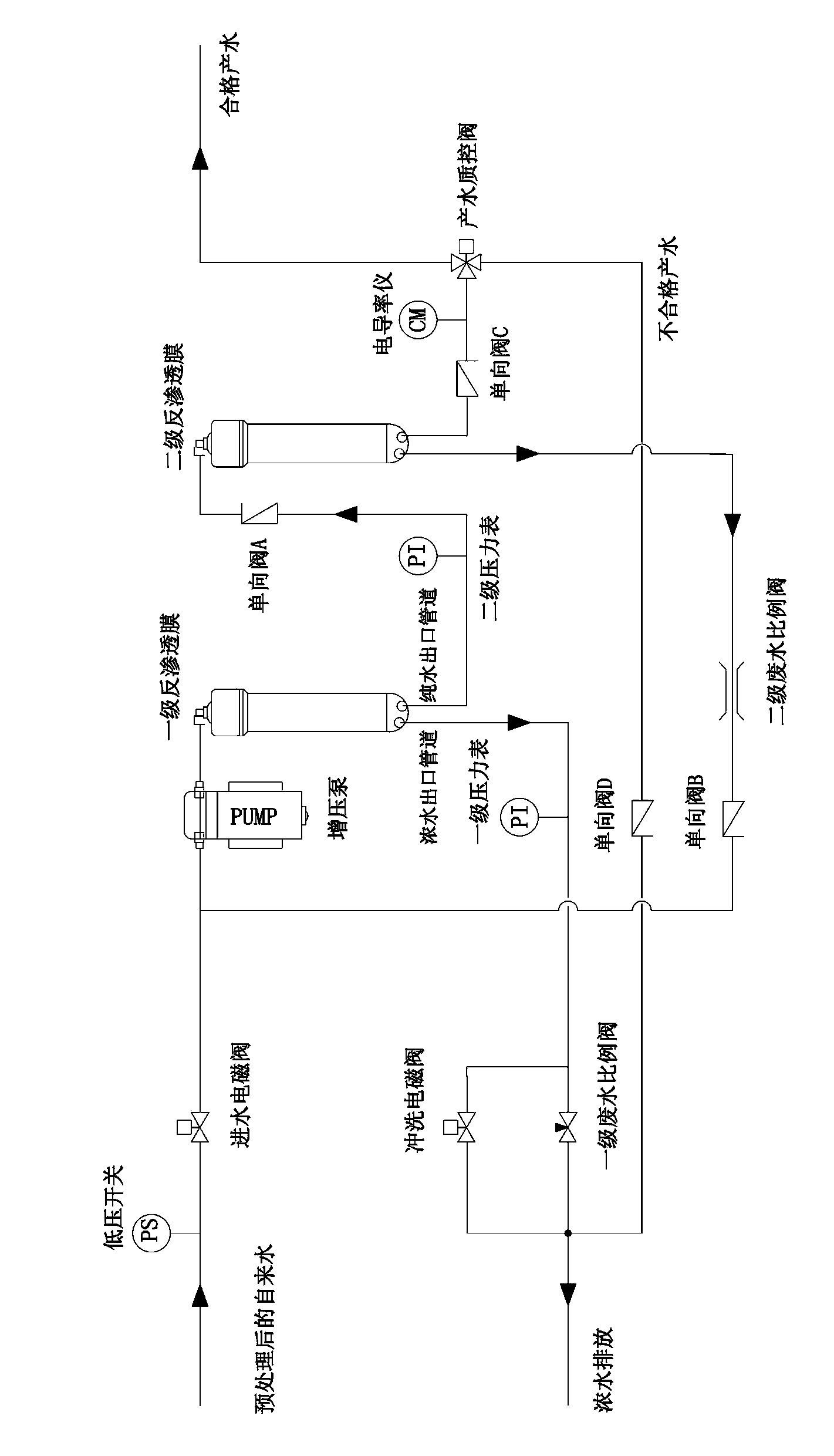

[0038] Such as figure 1 The shown small output single-pump double-stage reverse osmosis system includes a connected first-stage reverse osmosis membrane and a second-stage reverse osmosis membrane.

[0039] The tap water (flow ≥ 1.8LPM, pressure ≥ 1 bar) after pretreatment (usually 5um polypropylene fiber winding filter element + granular activated carbon filter element within the validity period) passes through the water source pressure sensor switch (low pressure switch) and water inlet solenoid valve in sequence . Then it is boosted by a booster pump (flow ≥ 1.2LPM7bar) and enters a first-stage reverse osmosis membrane (output 125GPD25℃, rated working pressure 50-60psi, desalination rate ≥96%).

[0040] Install a first-stage pressure gauge on the concentrated water outlet pipe of the first-stage reverse osmosis membrane, and then connect it to a first-stage wastewater proportional valve (adjustable or fixed, kv=0.6LPM), which is connected in parallel with a flushing soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com