Flow control module for RO water treatment system

A control module and water flow technology, applied in water treatment parameter control, permeation/dialysis water/sewage treatment, water/sewage treatment, etc., can solve problems such as difficult components and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

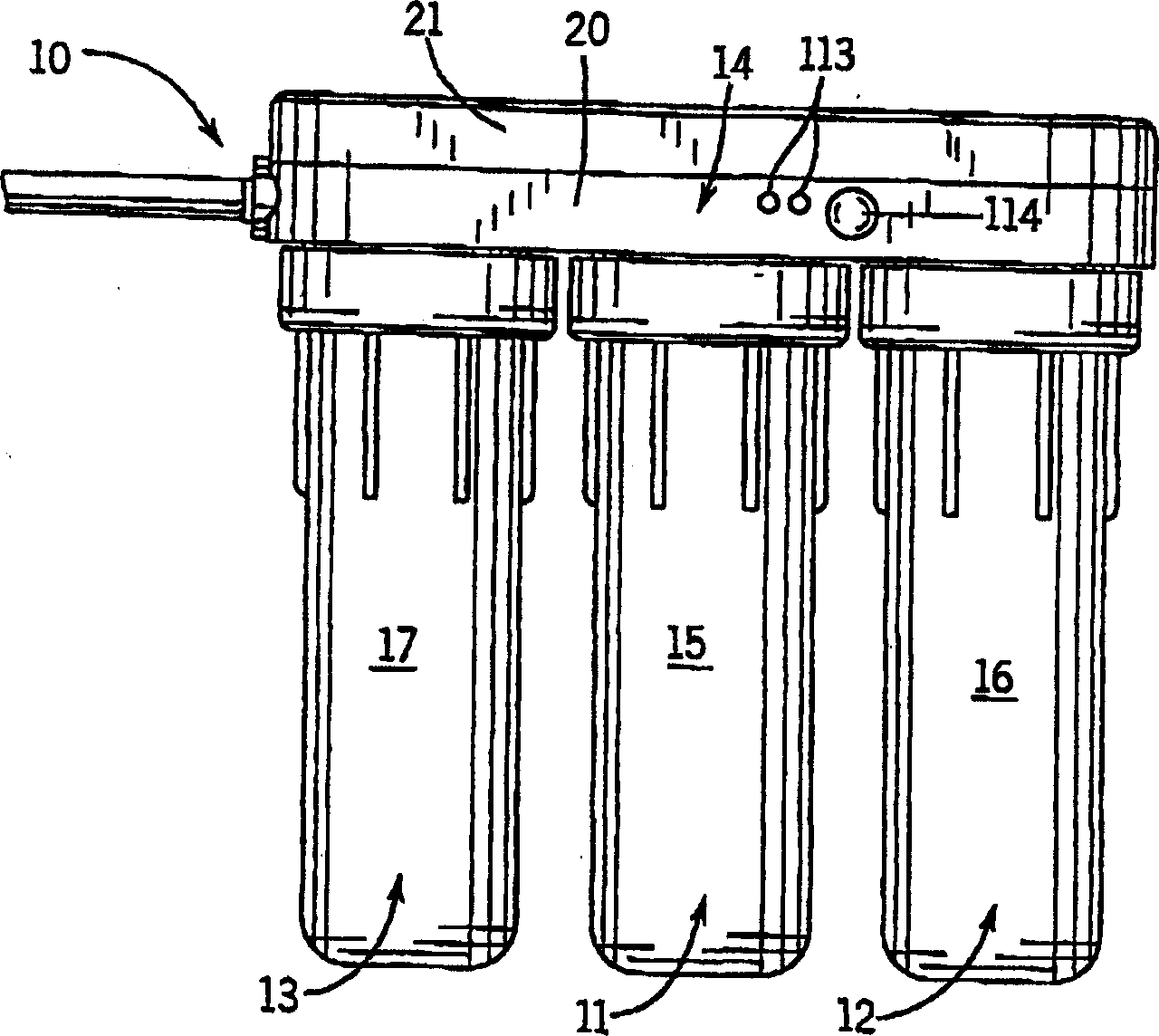

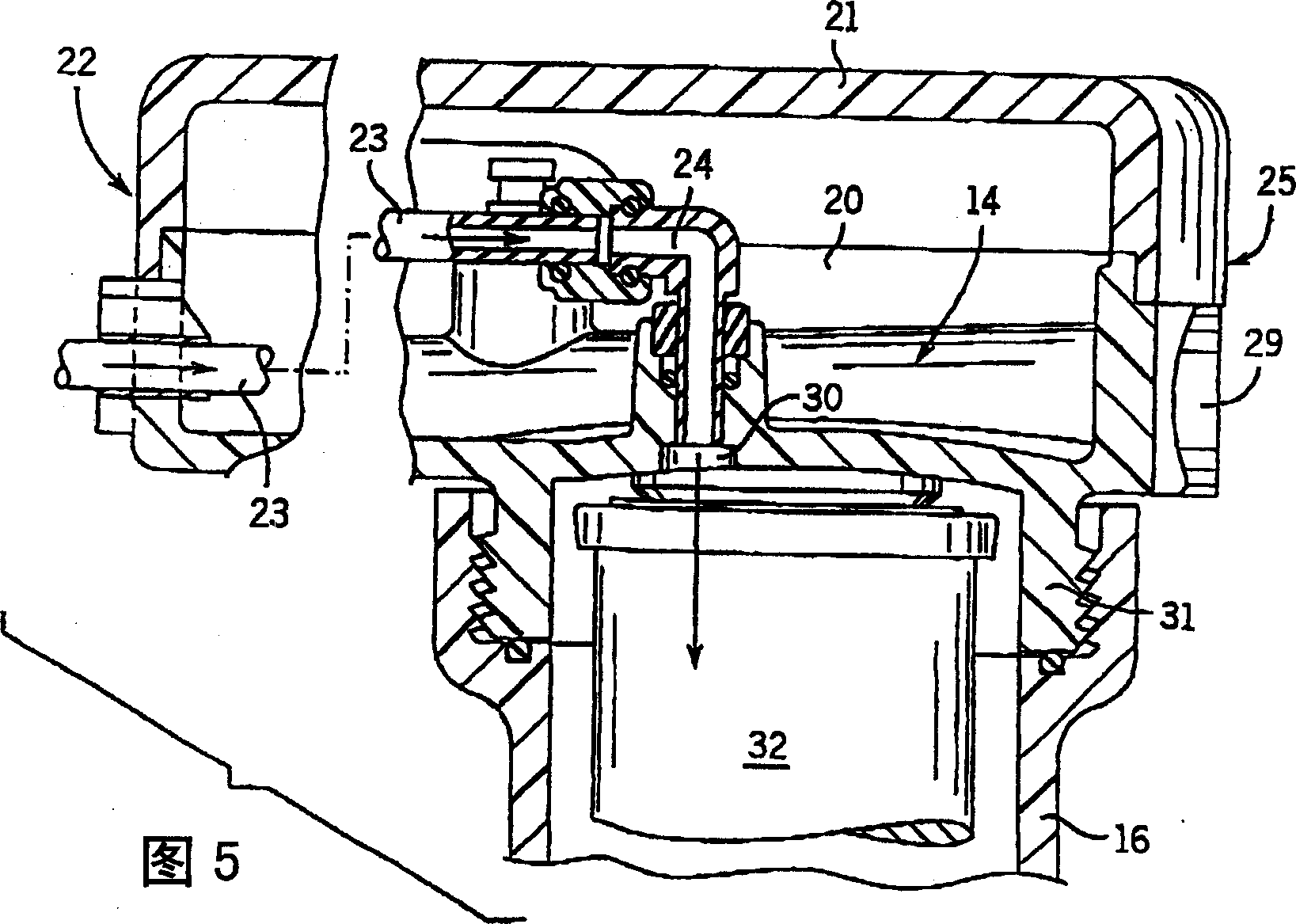

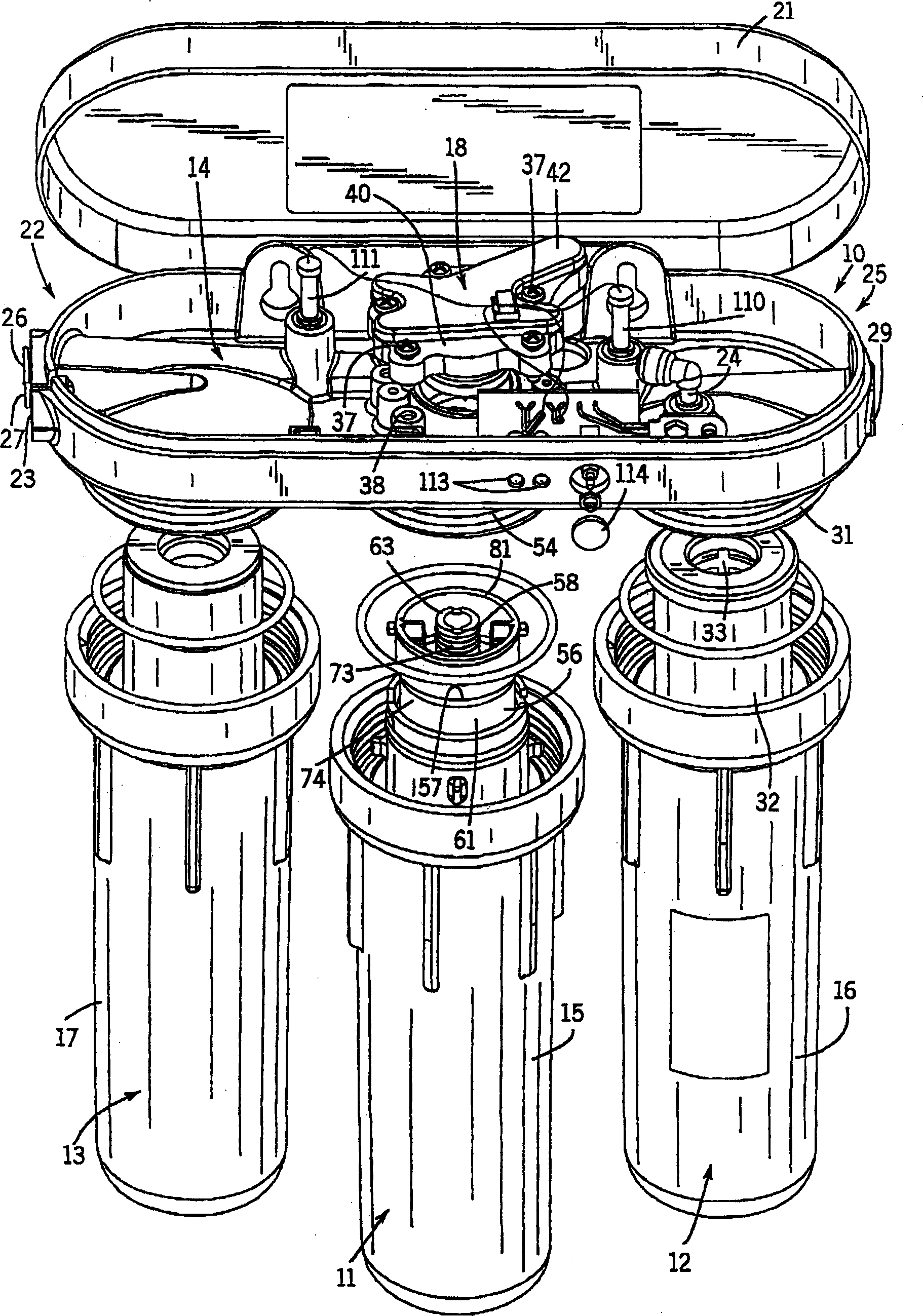

[0023] figure 1 Described is a water filtration system 10, including a reverse osmosis membrane filtration unit 11, inside the water filtration system 10, the reverse osmosis membrane filtration unit 11 is also sequentially connected to a pre-filtration unit 12 and a post-filtration through a common multiple assembly 14 Unit 13. These filter units 11, 12 and 13 comprise an open cylindrical housing 15, 16 and 17 respectively, each having a threaded upper connection for detachably connecting with the multi-element assembly 14, all using the disclosed method of the prior art method.

[0024] The multi-component assembly 14 is preferably a unitary injection molded structure, providing the operative connections of the filtration units 11, 12 and 13 and the connections between the two within them, as well as connections to the unfiltered source water, and to a filtered water storage tank 9, a tap 19 for distributing water to users (see Figure 16A and 16B )Connection. Although ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com