Novel membrane concentration system, process thereof and high-power concentration device

A concentration device and membrane concentration technology, applied in chemical instruments and methods, water treatment parameter control, water / sludge / sewage treatment, etc. problems, to avoid high investment and high operating costs, ensure long-term stable operation, and reduce investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

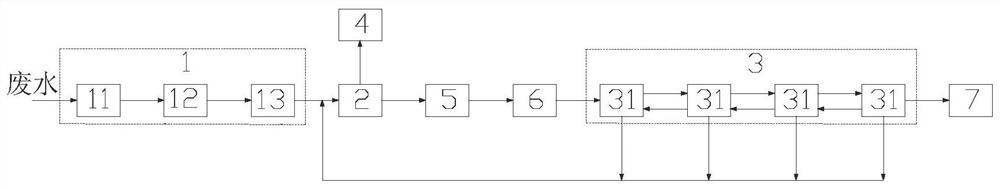

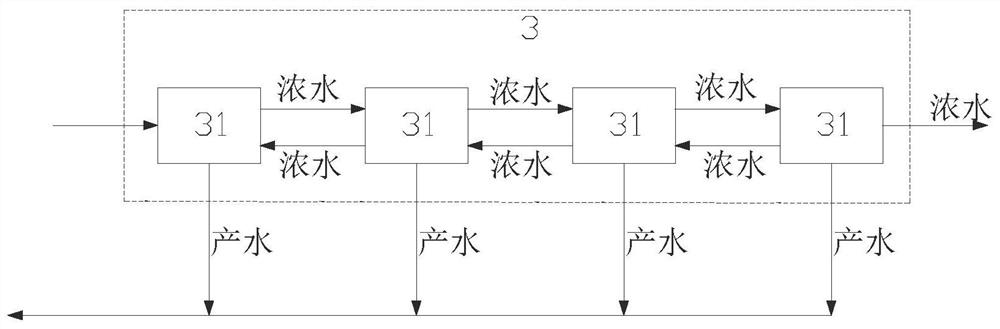

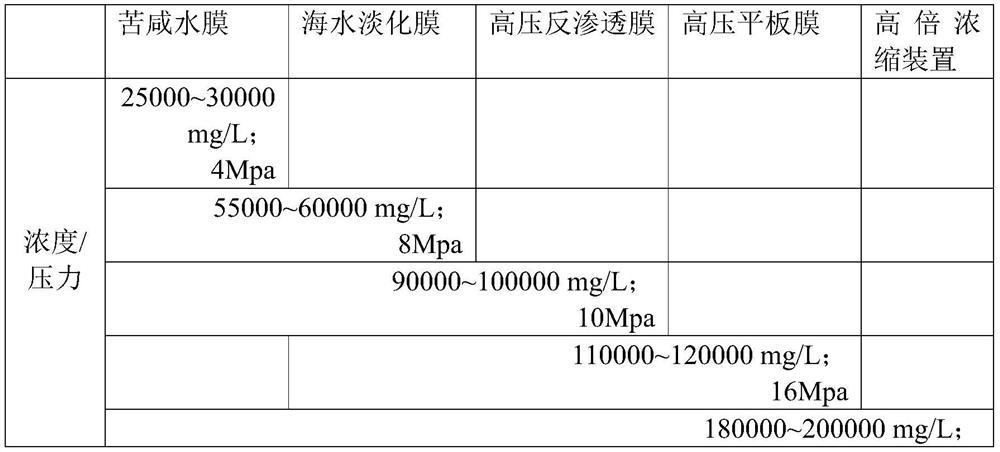

[0041] Such as figure 1 A novel membrane concentration system shown includes a pretreatment device 1, a reverse osmosis device 2, and a high-power concentration device 3; the pretreatment device 1 includes a high-density sedimentation tank 11, a quartz sand filter 12, and a submerged ultrafiltration membrane 13; The high-power concentration device 3 includes 4 stages of weak reverse osmosis membranes 31, and a return water inlet is provided on the water production side of each upper stage weak reverse osmosis membrane 31; the concentrated water outlet of the lower stage weak reverse osmosis membrane 31 is divided into two channels , one way is connected with the water inlet of the weak reverse osmosis membrane 31 of the next level, and the other way is connected with the backflow water inlet of the water production side of the weak reverse osmosis membrane 31 of the upper level. The weak reverse osmosis membrane 31 is produced by Toyobo Co., Ltd. The 8040-weak reverse osmosis ...

Embodiment 2

[0050] Utilize the technique of a kind of novel membrane concentration system of embodiment 1 to treat waste water, comprise following procedure: procedure 1 pretreatment; Procedure 2 preliminary concentration; Procedure 3 high power concentration; Also include procedure 4 except hard treatment and procedure pentoxide treatment; Wherein:

[0051] Step 1 Pretreatment: Wastewater enters the pretreatment device 1. Specifically, the waste water first enters the high-density sedimentation tank 11. By adding sodium carbonate, sodium hydroxide, hydrochloric acid, PAM, PFS and other agents into the high-density sedimentation tank 11, the Calcium ions, magnesium ions, silica, suspended solids and other substances in wastewater are removed; and the ratio of the dosage of sodium carbonate to the total amount of calcium ions in wastewater is (2.65~3):1, and the dosage of sodium hydroxide The amount added is 1.1 to 1.15 times the sum of the total amount of heavy metal ions and magnesium ion...

Embodiment 3

[0057] Utilize the technique of a kind of novel membrane concentration system of embodiment 1 to treat waste water, comprise following procedure: procedure 1 pretreatment; Procedure 2 preliminary concentration; Procedure 3 high power concentration; Also include procedure 4 except hard treatment and procedure pentoxide treatment; Wherein:

[0058] Step 1 Pretreatment: Wastewater enters the pretreatment device 1. Specifically, the waste water first enters the high-density sedimentation tank 11. By adding sodium carbonate, sodium hydroxide, hydrochloric acid, PAM, PFS and other agents into the high-density sedimentation tank 11, the Removal of calcium ions, magnesium ions, silica, suspended solids and other substances in wastewater. In this embodiment, the specific water quality of wastewater is: TDS content is 12110mg / L, SS is 21.5mg / L, COD cr The total hardness is 275.8mg / L, the total hardness is 483mg / L, the chloride ion is 4076mg / L, the sulfate radical is 2243mg / L, the bicarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com