Process and device for recovering reverse osmosis-nanofiltration combination membrane separation material of fermentation liquor

A recovery device and reverse osmosis technology, applied in the field of environmental engineering, to achieve the effect of increasing extraction rate, improving production efficiency, and shortening extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

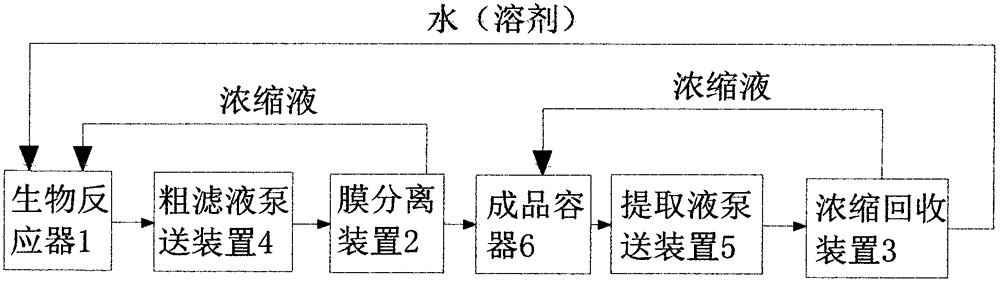

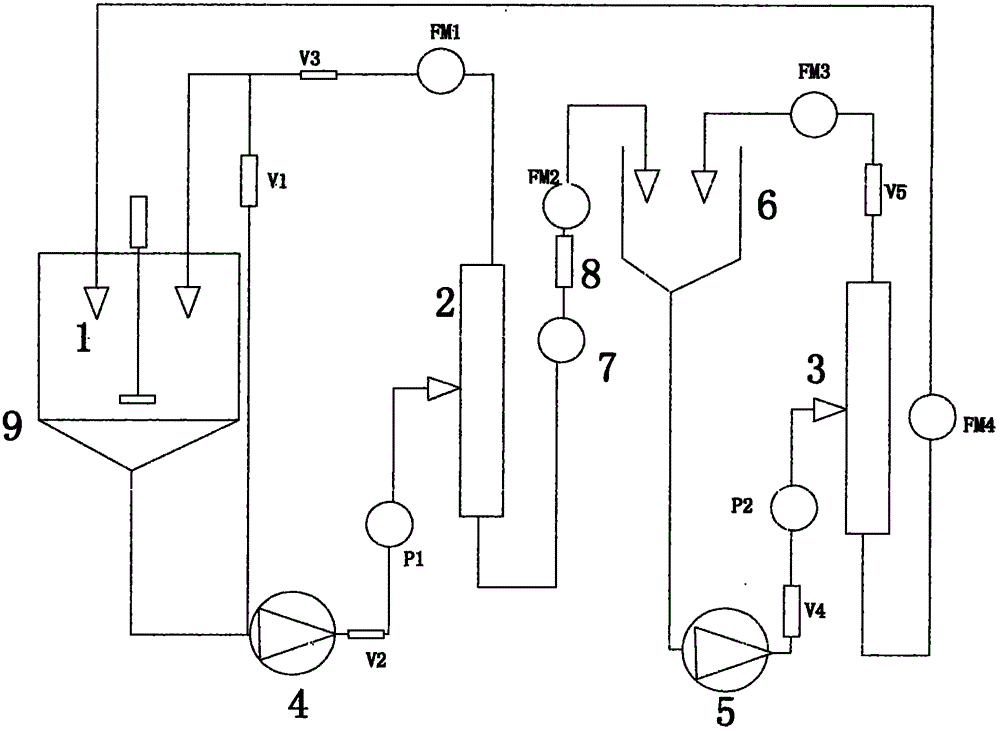

[0021] Such as figure 1 As shown, the fermentation liquid reverse osmosis-nanofiltration combined membrane separation material recovery process includes bioreactor circulation extraction, membrane separation, product concentration, water recovery and other processes. Each process is connected in sequence and closed to form a cycle process system. The primary processed material enters the bioreactor (containing water and biological enzymes), and is leached according to the process requirements and then undergoes coarse filtration. The crude filtrate (including raw materials, biological enzymes and water) is pumped into the membrane separation device by the crude filtrate pumping device 4 2 Carry out membrane separation and extraction, the extract solution (water and water-soluble hydrolyzed active ingredients) that pass through the separation membrane enters the finished product container 6, and the slag that does not pass through the separation membrane (biological enzymes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com