Forward osmosis membrane flow system and composite semipermeable membrane for forward osmosis membrane flow system

A technology of composite semipermeable membrane and flow system, applied in the field of composite semipermeable membrane, can solve the problems of insufficient system efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

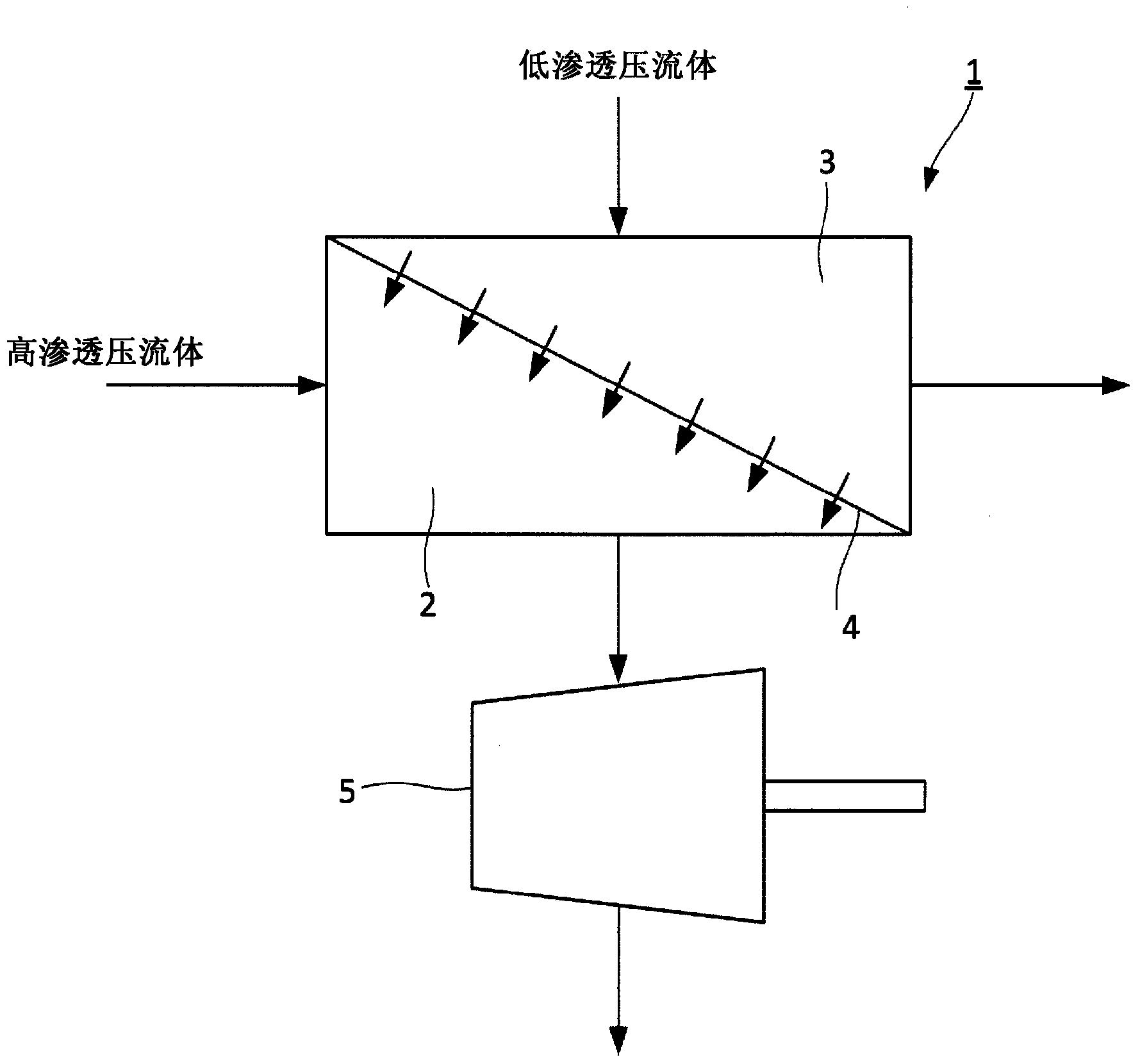

Problems solved by technology

Method used

Image

Examples

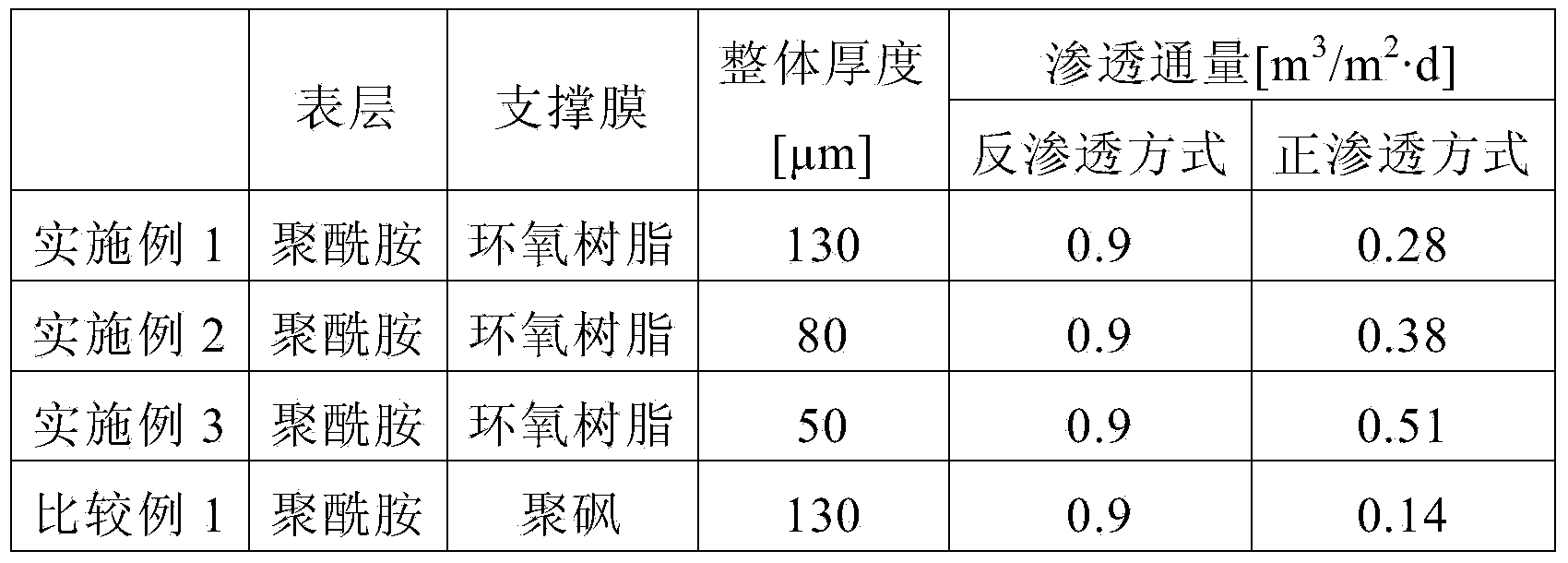

Embodiment 1

[0076] (Manufacturing of epoxy resin porous substrate)

[0077] 139 parts by weight of bisphenol A type epoxy resin (manufactured by Japan Epoxy Resin Corporation, Epicoat 828), 93.2 parts by weight of bisphenol A type epoxy resin (manufactured by Japan Epoxy Resin Corporation, Epicoat 1010), two (4-amino Cyclohexyl) methane 52 parts by weight and polyethylene glycol 200 (manufactured by Sanyo Chemical Industry Co., Ltd.) 500 parts by weight epoxy resin composition is filled in a cylindrical mold (outer diameter 35 cm, inner diameter 10.5 cm) to a height of 30 cm , cured at room temperature at 25°C for 12 hours, and then reacted and cured at 130°C for 18 hours to make a cylindrical resin block. While rotating the resin block around the axis of the cylinder, it was continuously cut into thin slices with a thickness of 145 μm from the surface using a cutting device (manufactured by Toshiba Machine Co., Ltd.) to obtain a long epoxy resin sheet (length: 100 m) . The epoxy resin ...

Embodiment 2

[0081] The composite semipermeable membrane of Example 2 was obtained in the same manner as in Example 1 except that the cutting thickness of the resin block was changed to 90 μm in preparation of the epoxy resin porous membrane. The finally obtained composite semipermeable membrane of Example 2 had a thickness of 80 μm.

Embodiment 3

[0083] The composite semipermeable membrane of Example 2 was obtained in the same manner as in Example 1 except that the cutting thickness of the resin block was changed to 55 μm in preparation of the epoxy resin porous membrane. The finally obtained composite semipermeable membrane of Example 3 had a thickness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com