Drill bit used for glass drilling and having automatic chip removing function

An automatic drill bit technology, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of increasing the labor load of the operator, not being able to recycle again, and having no recycling device, so as to avoid cleaning difficulties, avoid waste, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

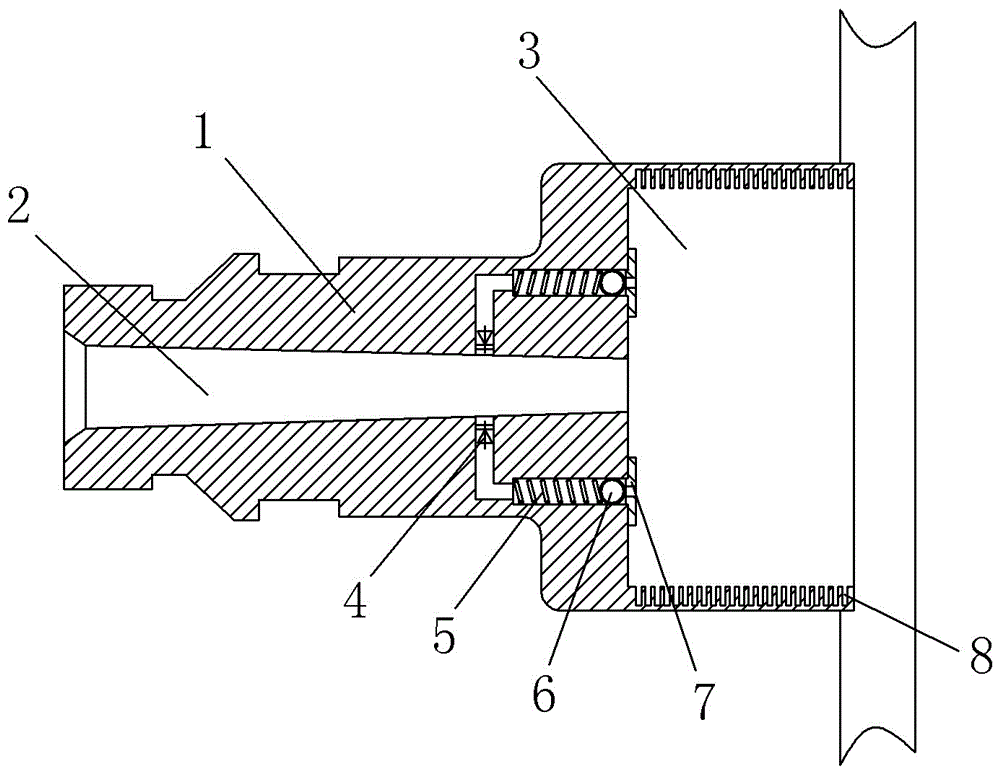

[0020] The reference signs in the drawings of the description include: drill body 1 , water delivery pipe 2 , drill cavity 3 , safety valve 4 , spring 5 , steel ball 6 , positioning plate 7 , groove 8 .

[0021] The embodiment is basically as attached figure 1 Shown: a drill bit for glass drilling with automatic chip removal function, including a drill body 1, a water delivery pipe 2 is opened on the left side of the drill body 1, and a drill cavity 3 is opened on the right side of the drill body 1 for water delivery The pipeline 2 communicates with the drill bit cavity 3, and the width of the drill body 1 in the up and down direction is greater than the width of the water delivery pipeline 2 in the up and down direction. In this embodiment, the water delivery pipeline 2 is a water delivery pipeline 2 with a tapered structure, wherein the water delivery pipeline 2 The sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com