Solid waste or biomass high-efficiency pyrolysis oil-producing system

A solid waste and biomass technology, applied in the field of resources and environment, can solve the problems of low separation efficiency, low heating rate of reactor, poor heat transfer effect, etc., and achieve the effect of avoiding tar condensation and improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Solid waste or biomass pyrolysis liquefaction technology refers to the direct pyrolysis of biomass under the conditions of medium temperature of about 500°C, high heating rate and extremely short gas residence time (about 2s). Liquid oil is obtained by rapid cooling.

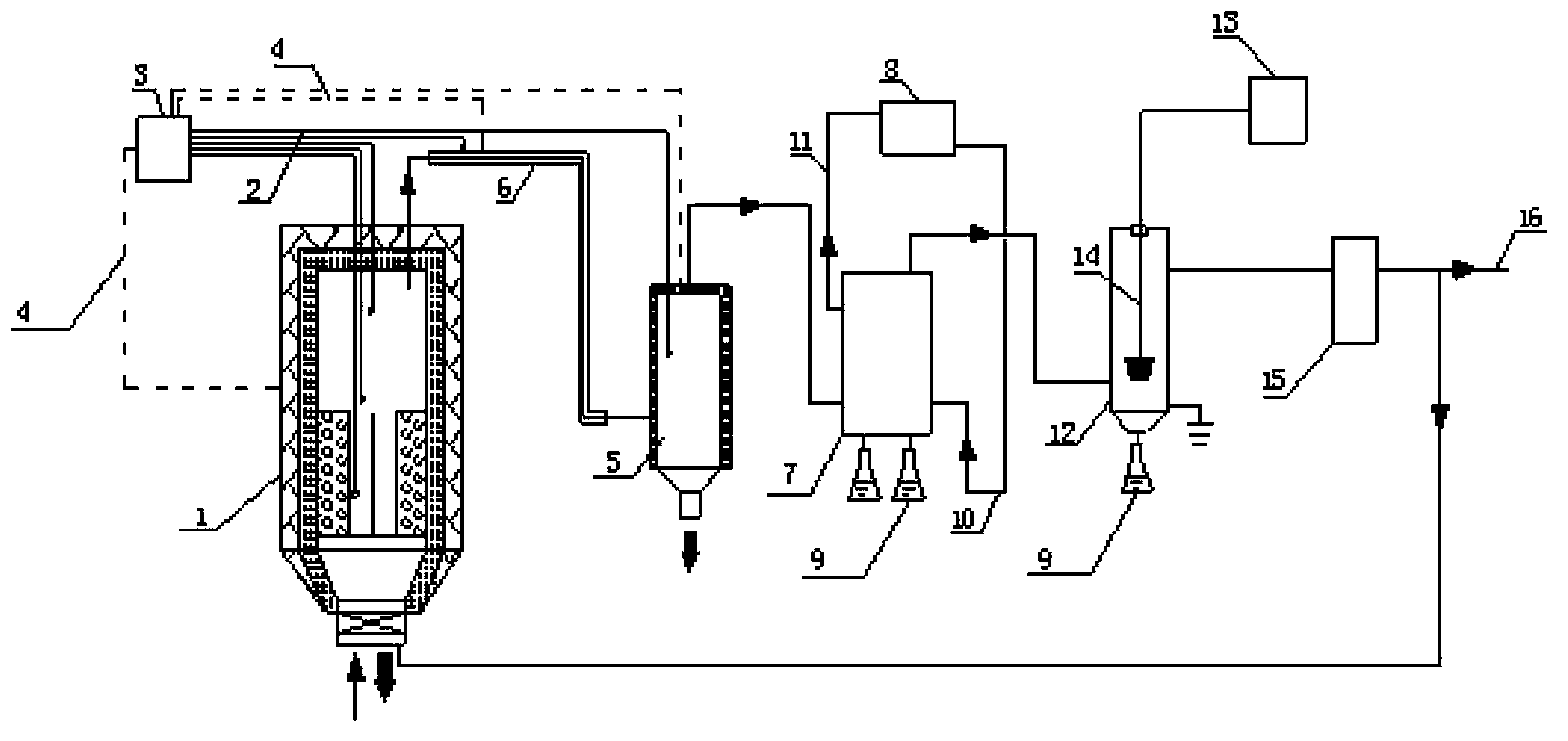

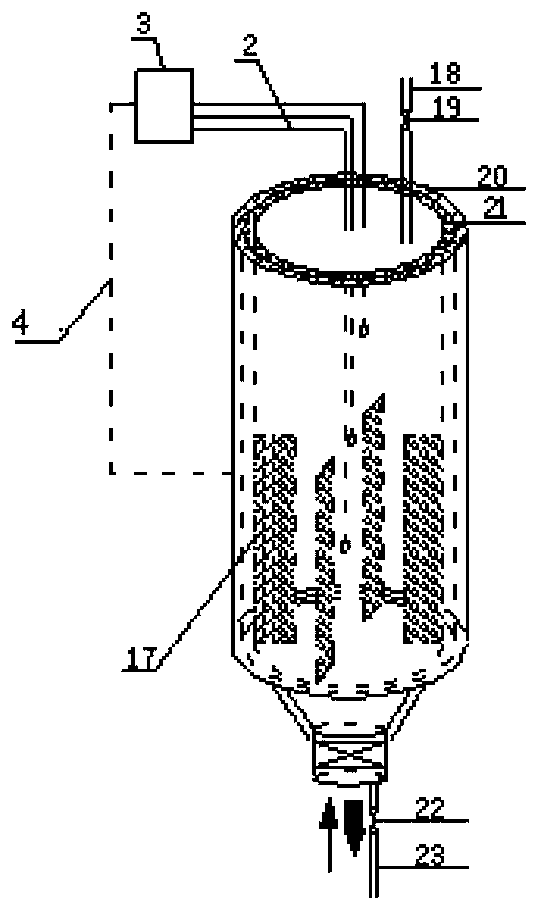

[0022] Such as figure 1 As shown, the solid waste or biomass is roughly or regularly crushed (the crushing scale depends on the pyrolysis reaction device), and then fed into the pyrolysis furnace 1. The furnace type can be selected from various current fixed bed, fluidized bed and other furnace types. The pyrolysis furnace 1 can adopt heating methods such as external heating or internal heating, and the purge gas is an inert gas such as nitrogen. An electric furnace wire 22 is arranged outside the pyrolysis reactor 1 as a heat source and also serves as a heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com