Dust-free paper shredder

A technology of paper shredders and paper scraps, which is applied in the field of dust-free paper shredders, can solve the problems of paper scraps and dust cleaning difficulties, and achieve the effect of avoiding cleaning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

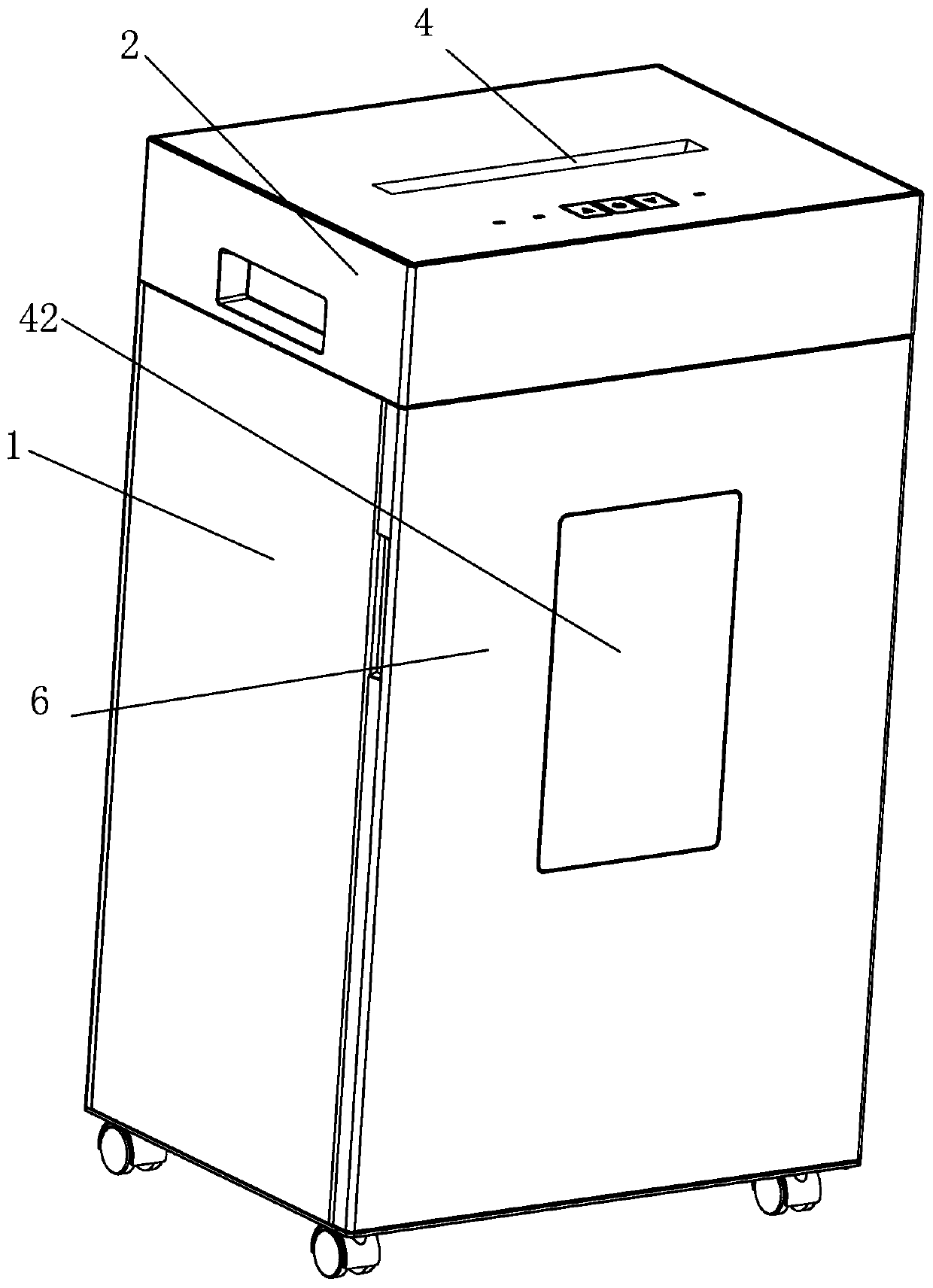

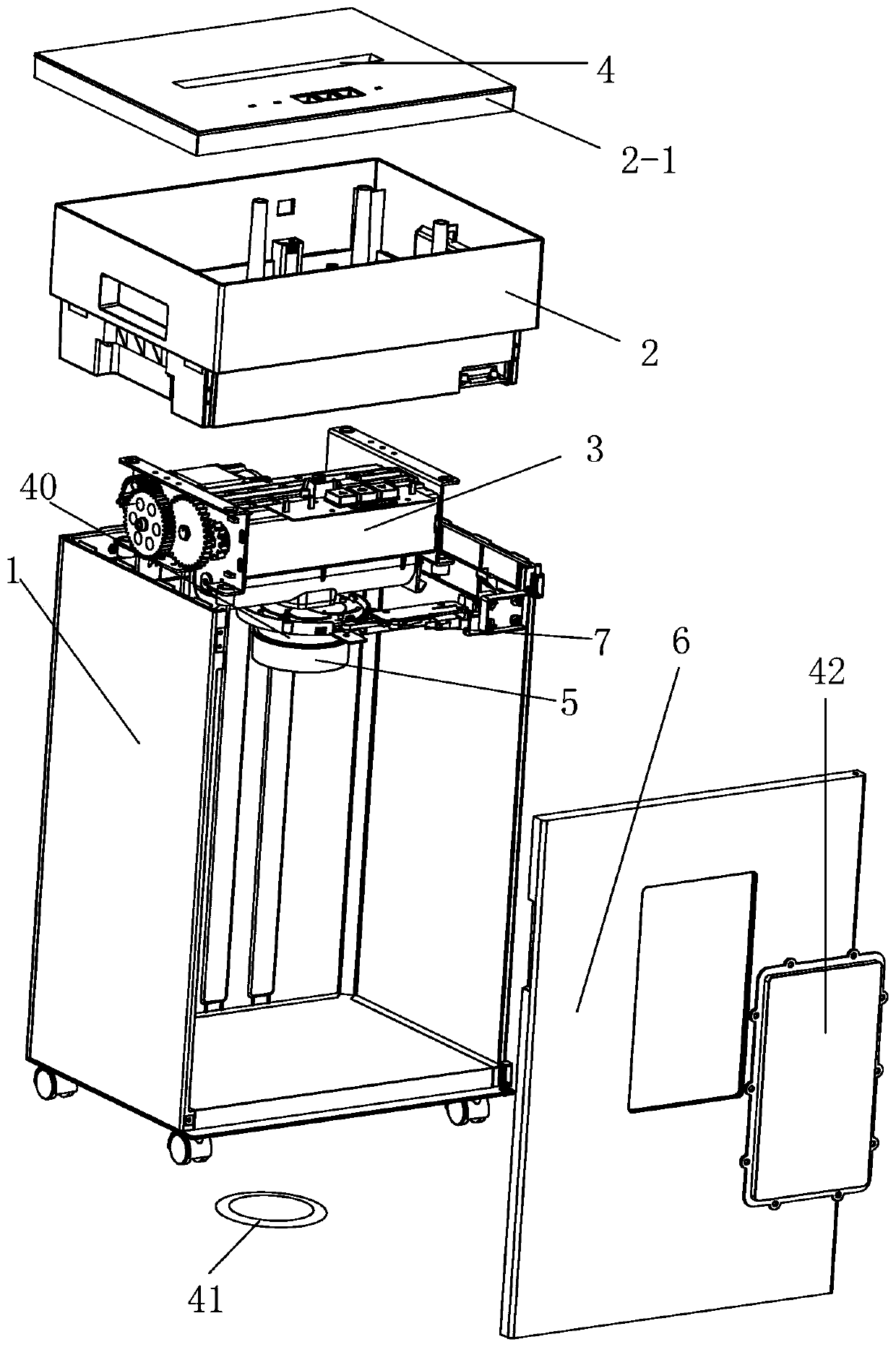

[0029] Such as Figure 1 to Figure 6 As shown, a dust-free paper shredder disclosed in this embodiment includes a box body 1, a crushing part 2 is provided above the box body 1, a shredder assembly 3 is arranged in the crushing part 2, and a shredder assembly 3 is arranged on the crushing part 2. There is a paper inlet 4 positioned at the top of the shredder assembly 3 (the paper inlet 4 is located on the cover plate 2-1 above the crushing part 2), and a paper inlet 4 is provided below the shredder assembly 3. A paper scrap outlet 5, the paper scrap outlet 5 is located in the box body 1, and a cover door 6 is hinged on the side of the box body 1, and the upper port of the paper scrap outlet 5 is provided and can be moved according to It is necessary to open or close the dial mechanism 7 of the paper dust outlet 5, and when the dial mechanism 7 is opened, it can ensure the connection between the paper dust outlet 5 and the paper inlet 4. On the contrary, when the dial mechanism...

Embodiment 2

[0037] Such as Figure 7 to Figure 8 As shown, in the dust-free shredder disclosed in this embodiment, in order to realize the state of automatic opening or closing and ultimately facilitate operation, a pressure plate is provided on the inner side of the cover door 6 in order to realize the state of automatically opening or closing and ultimately facilitate operation. 20. One side of the pressing plate 20 is an inclined portion 21, and a fixing seat 22 is provided on the crushing portion 2 (the fixing seat 22 is fixed on the lower surface of the cover plate 2-1 above the crushing portion 2), and in the fixing seat 22 The horizontal sliding connection is connected with the operating connecting rod 23 that drives the dial 13 to toggle in the arc-shaped gap 17. The third connecting shaft 46 is arranged below one end of the operating connecting rod 23, and the third connecting shaft 46 is arranged on the moving rod 18. The second sliding groove 43 matched with the connecting shaf...

Embodiment 3

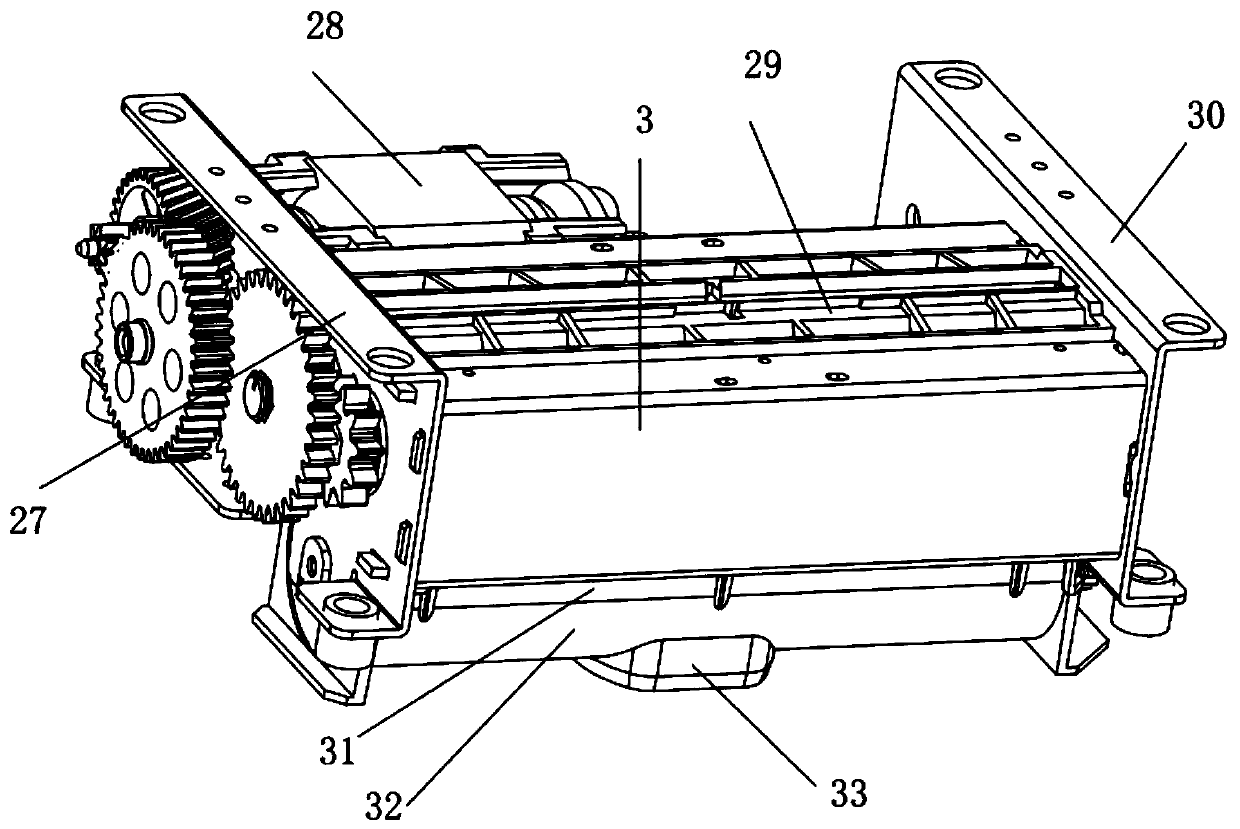

[0041] Such as Figure 9 to Figure 13 As shown, in the dust-free paper shredder disclosed in this embodiment, in order to avoid the problem of internal blockage or residual waste paper when conveying shredded paper, the shredder assembly 3 includes a bracket 27 placed in the shredder part 2, The motor 28 on the support 27 and the paper shredder 29 electrically connected with the motor 28, the support 27 includes two connecting frames 30 respectively on the left and the right, and the motor 28 is located on the connecting frame 30 on the left side. 29 is provided with a shredded paper conveying mechanism 31. The shredded paper conveying mechanism 31 includes a shredded paper conveying channel 32 located between two connecting frames 30 and with an arc-shaped bottom. The shredded paper feeding port 33 connected with the shredded paper outlet 5 is rotatably connected to the shredded paper conveying impeller 34 in the shredded paper conveying channel 32. The paper conveying screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com