Mortar stirring cylinder

A mortar mixing and cylinder technology, which is applied to mixer accessories, dissolving, mixers, etc., can solve the problems of poor mixing effect of the sandbox mixing cylinder and the solidification of mortar on the inner wall of the cylinder, so as to avoid cleaning difficulties and improve the utilization of mortar. High rate, full mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

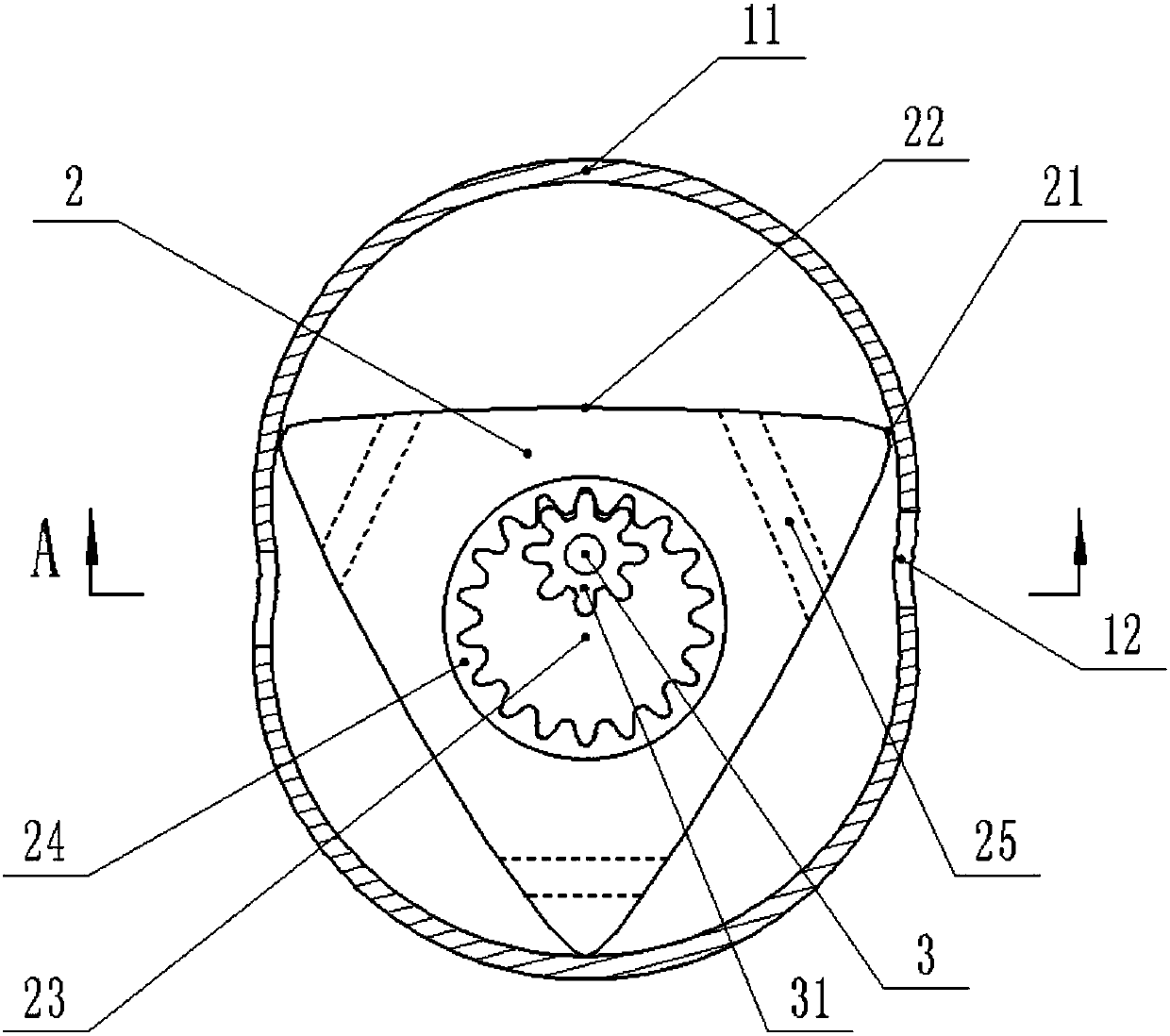

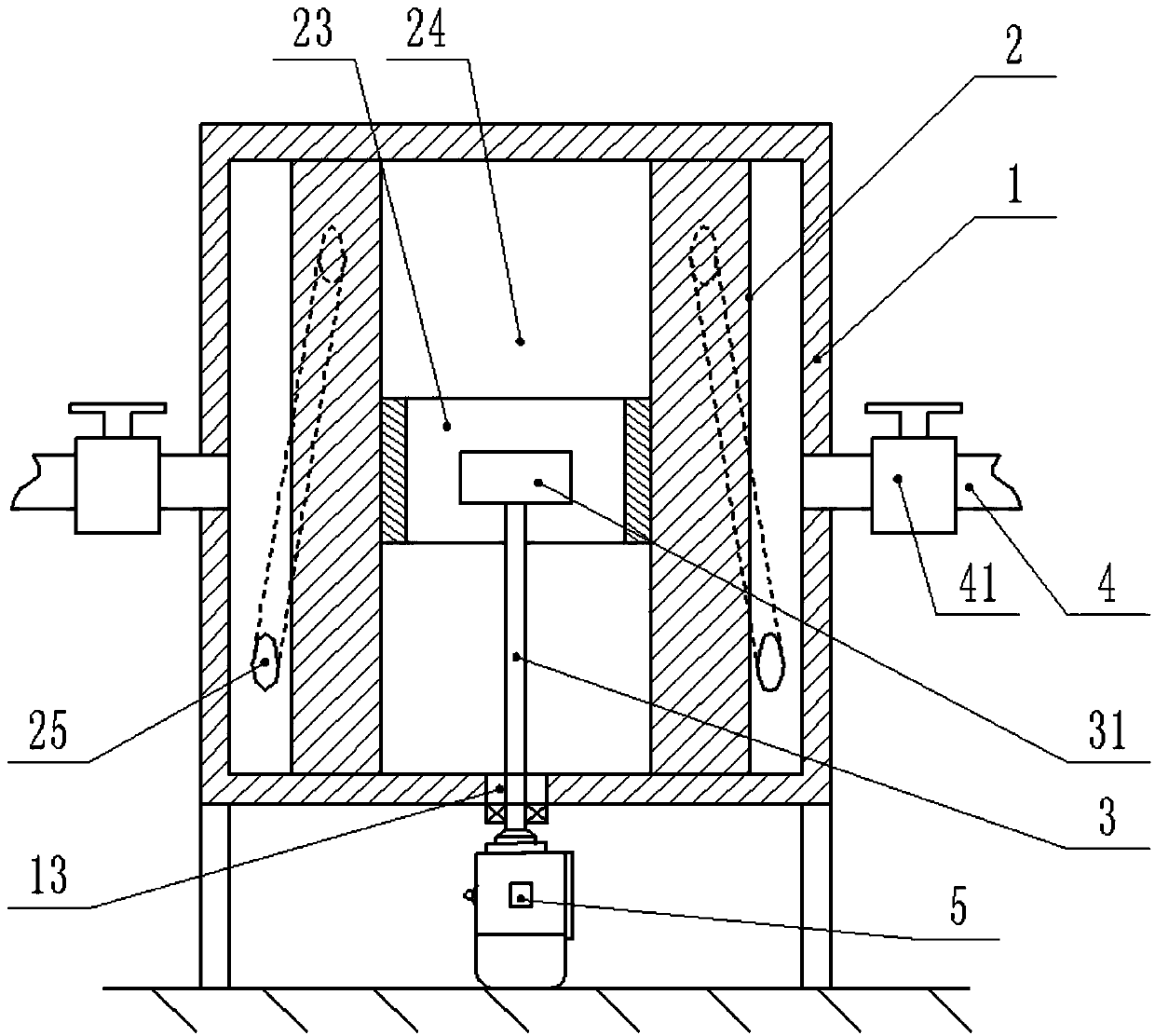

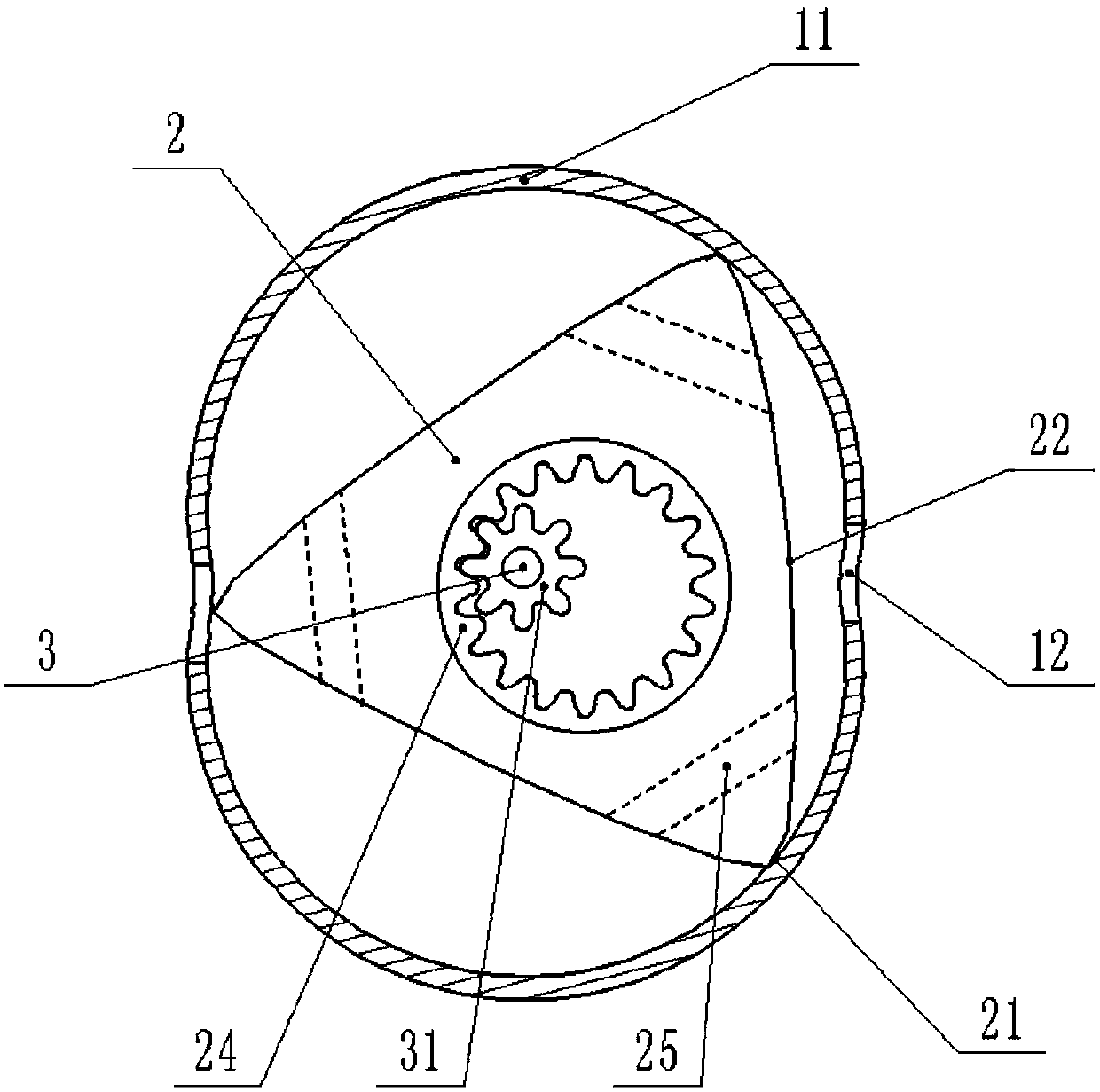

[0034] The reference signs in the drawings of the specification include: cylinder block 1, circular arc portion 11, thin waist portion 12, first through hole 13, triangular rotor 2, side edge 21, side surface 22, second through hole 23, inner ring gear 24, the communication channel 25, the rotating shaft 3, the gear 31, the discharge pipe 4, the valve 41, and the rotating motor 5.

[0035] like figure 1 and figure 2 The mortar mixing cylinder shown includes a cylinder body 1, a triangular rotor 2 and a rotating shaft 3. The top wall of the cylinder body 1 is a flat top, the bottom wall of the cylinder wall is a flat bottom, the side wall of the cylinder body 1 is in the shape of an "8", and the side wall of the cylinder body 1 includes two arc parts 11 and two thin waist parts 12 , The two thin waists 12 are connected with a discharge pipe 4, and the discharge pipe 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com