Patents

Literature

44results about How to "Play the role of scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

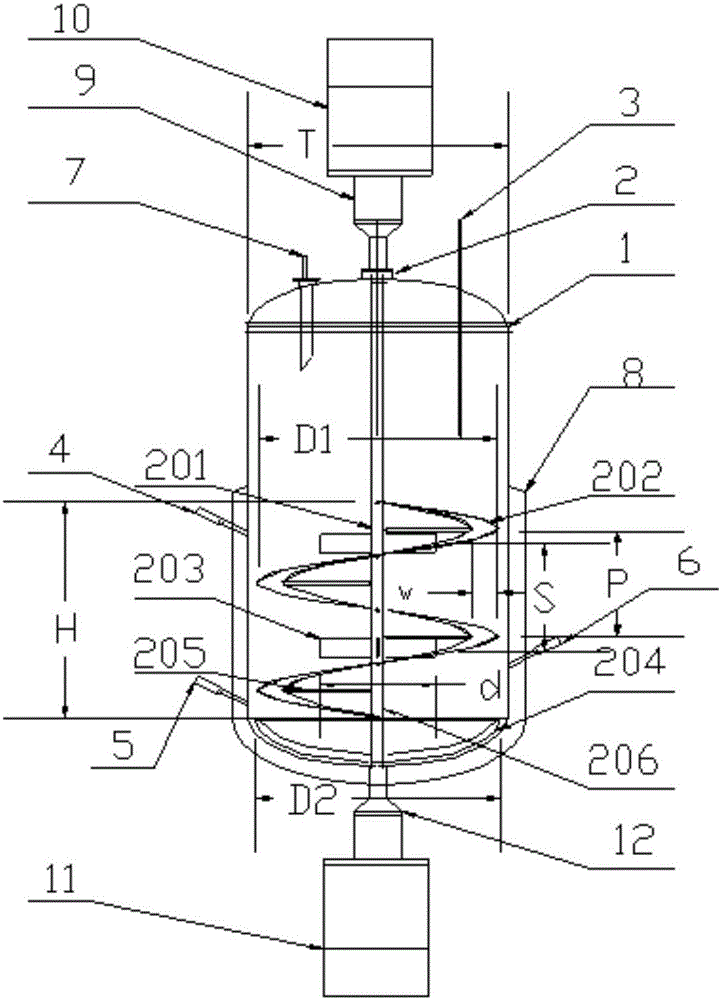

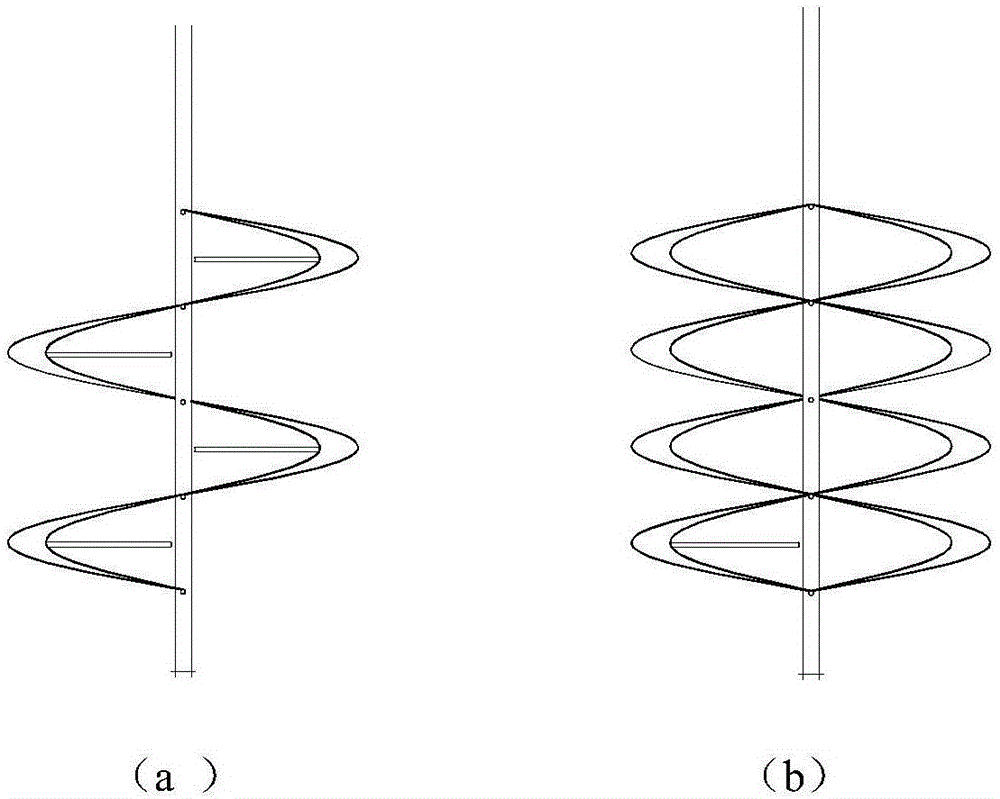

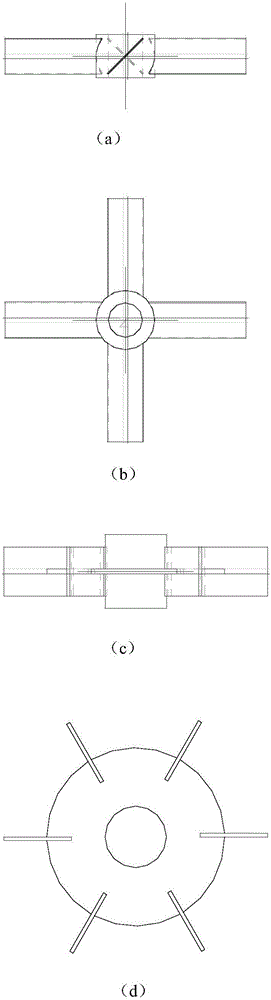

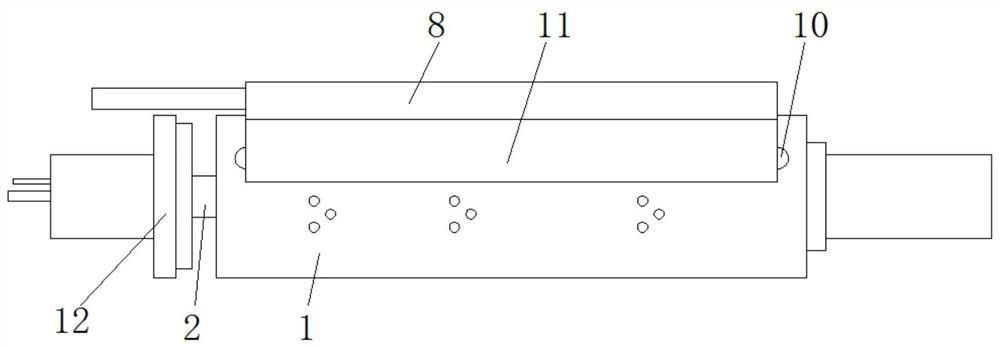

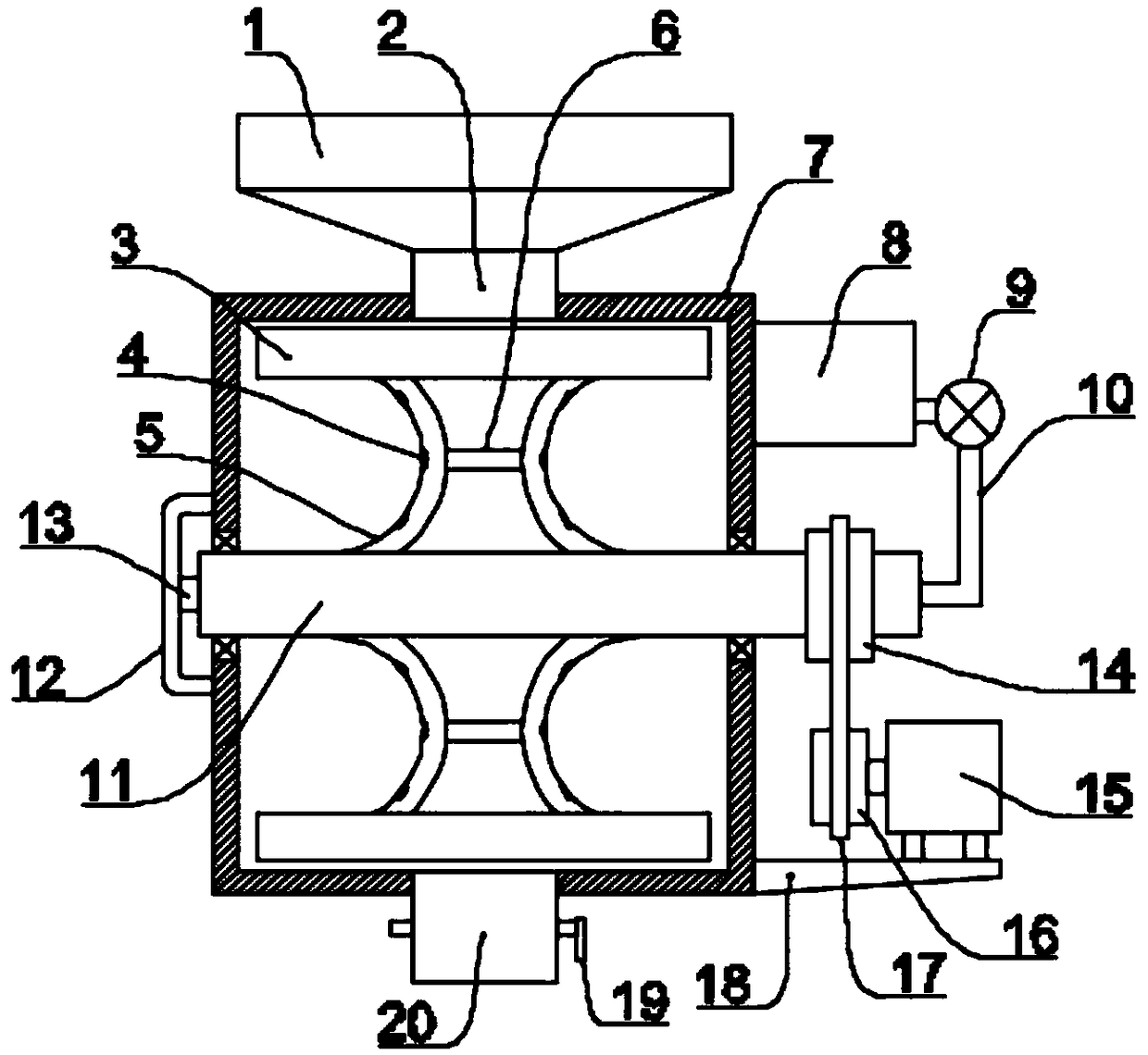

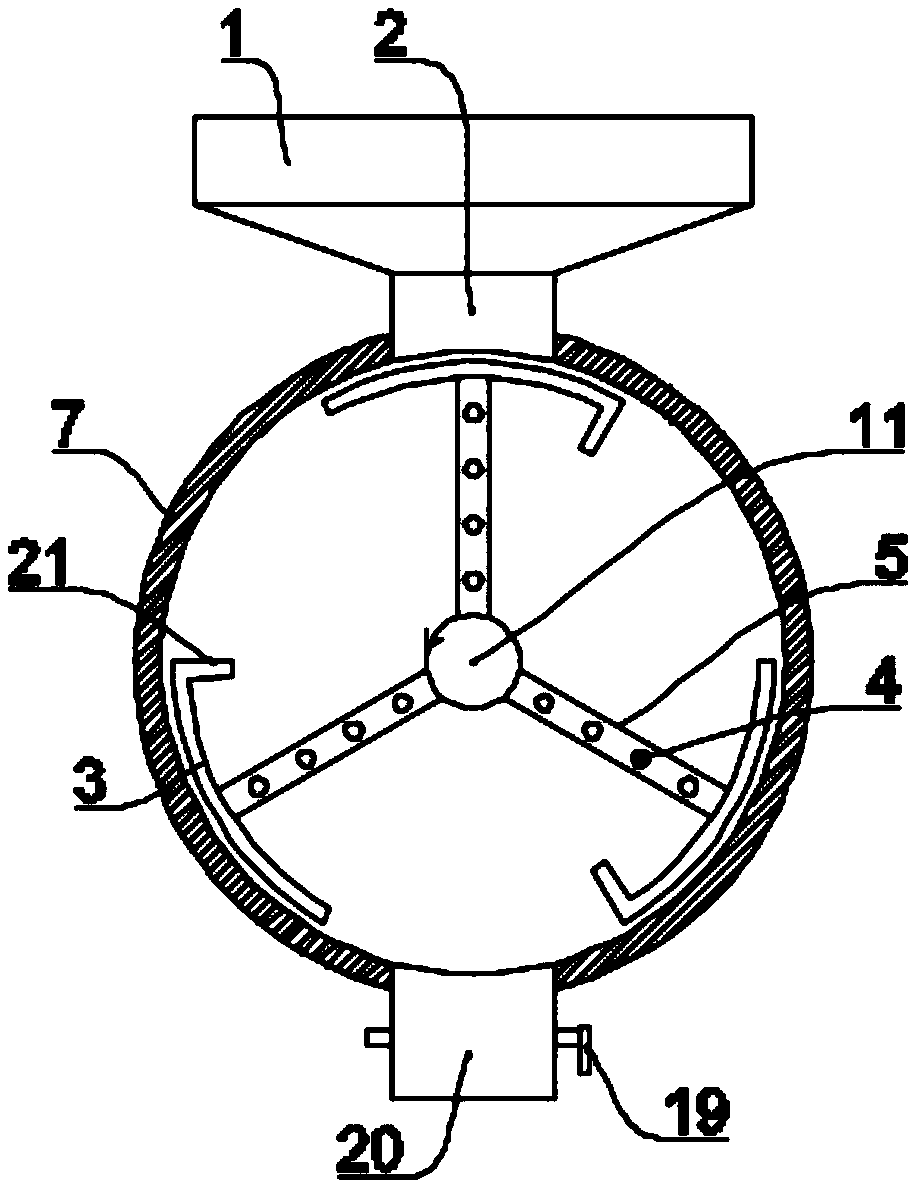

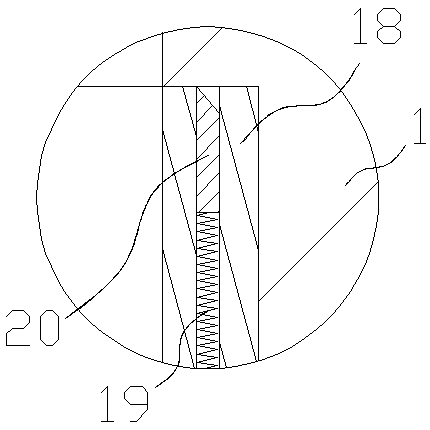

Coaxial different-speed combined paddle reactor

InactiveCN106635788AUniform heat transferImprove heat transfer performanceBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassEngineering

The invention relates to a coaxial different-speed combined paddle reactor which is used in synchronous saccharifying fermentation of biomass-based ethanol production. The reactor comprises a cylindrical vertical vessel and a stirring device axially installed in the vessel, wherein the comprises a helical ribbon type stirring paddle helically arranged around a stirring shaft from top to bottom, a lower layer stirring paddle installed on the stirring shaft near the lower part of the cylindrical vertical vessel, and a bottom stirring paddle installed at the bottom end of the stirring shaft at the bottom of the cylindrical vertical vessel. According to the invention, a three-blade combination mode is adopted, so that the effects of shearing and circulating materials are achieved; under the combined action of the above two flows, the materials added into the reactor can be quickly mixed, so that the energy consumption distribution in a stirring tank is more uniform, thereby realizing efficient utilization of energy; the reactor can solve the problem of wall sticking of the materials near the wall surface; the reactor reinforces heat transfer, promote uniform suspension of granules and is simple in structure; the structure and operation parameters can be easily adjusted; and the reactor is convenient to process, manufacture and install.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

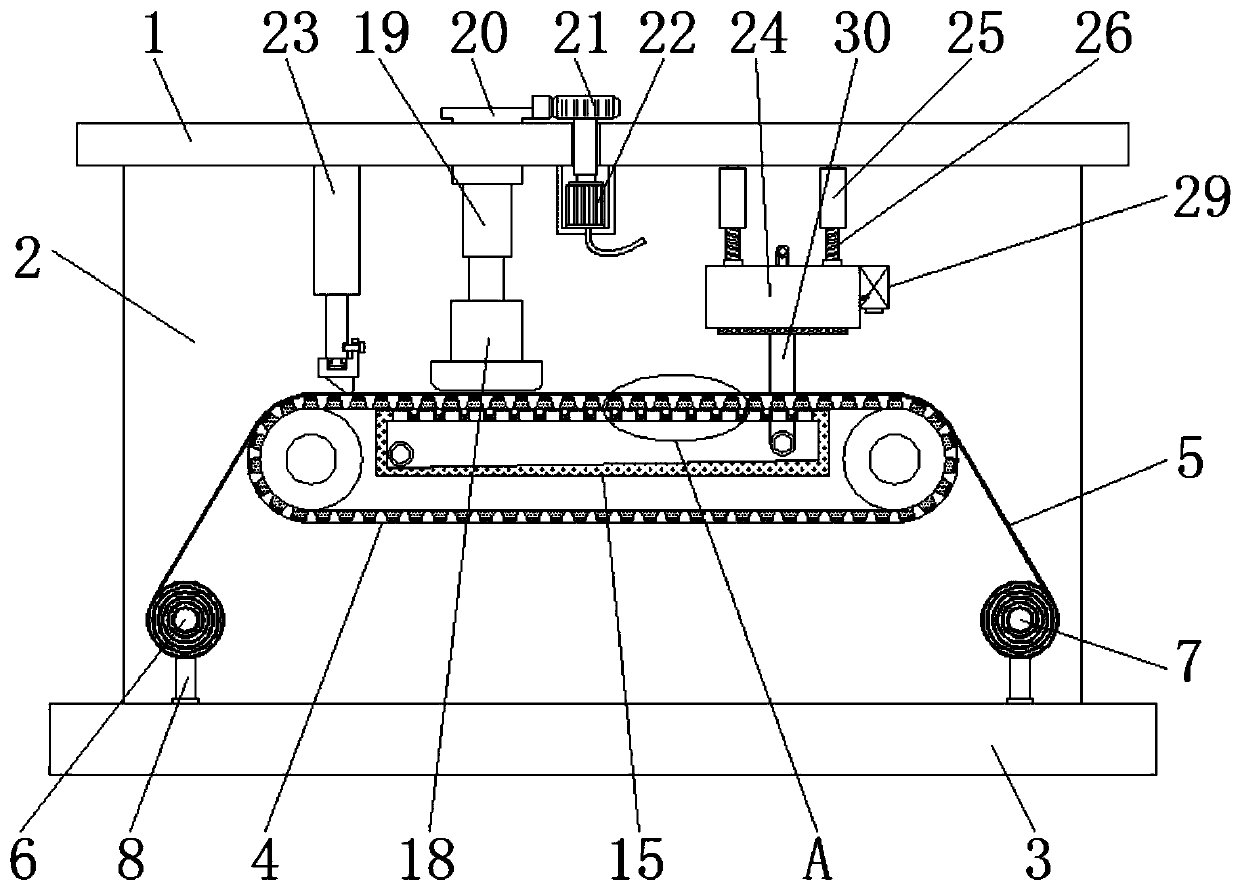

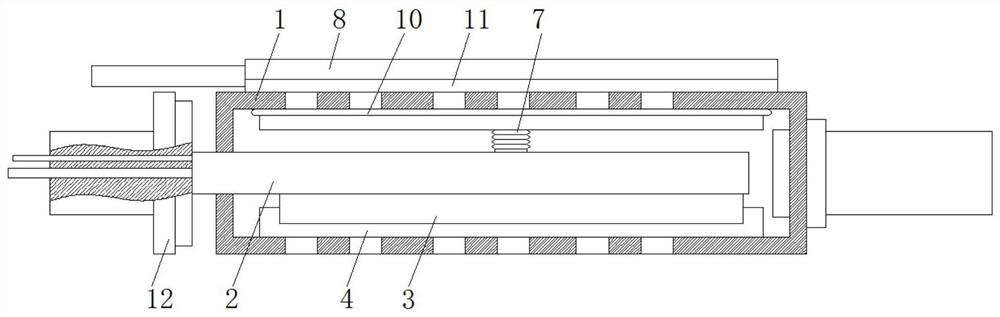

Textile ironing device capable of preventing cloth from sliding

InactiveCN110924023APrevent slidingEasy to fixMechanical cleaningPressure cleaningElectric machineryContact position

The invention discloses a textile ironing device capable of preventing cloth from sliding. The device comprises an upper top plate, wherein the front end and the rear end of the upper top plate are both fixedly connected to side plates; a conveyor belt is arranged between the upper top plate and a bottom plate; the cloth is coiled on the outer surface of the conveyor belt; the left end of the cloth is wound on an unwinding roller; the front ends and the rear ends of the unwinding roller and a winding roller are placed on a supporting frame; first balls are uniformly inlaid into the contact position of the supporting frame and the unwinding roller and the contact position of the supporting frame and the winding roller; the front ends and the rear ends of the unwinding roller and the windingroller are connected to limiting blocks; the limiting block on the rear side is connected to an adjusting rod; and the limiting block on the front side of the winding roller is connected to the output end of a first motor. According to the textile ironing device capable of preventing the cloth from sliding, the fixation in a cloth ironing process is facilitated, the cloth can be conveniently subjected to surface drying treatment, the cloth ironing flatness can be conveniently improved, and the dust and the fluff can be effectively removed.

Owner:杨锋

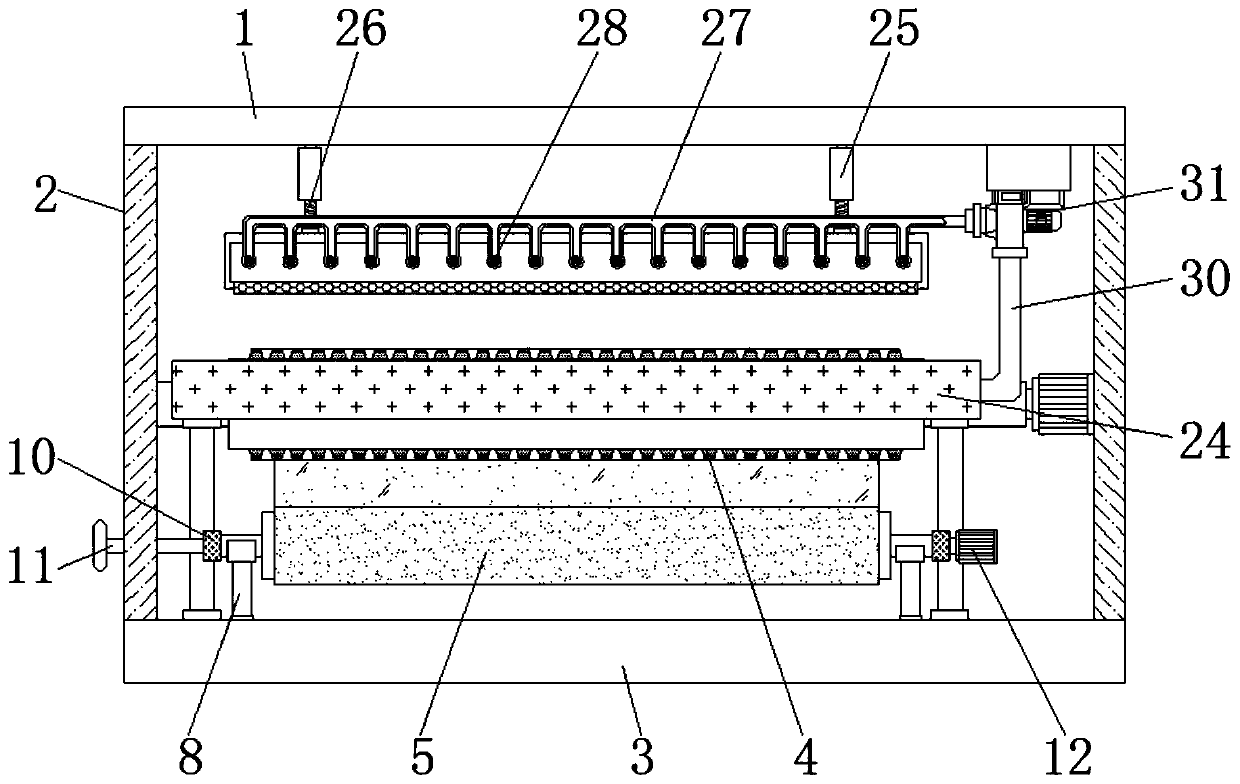

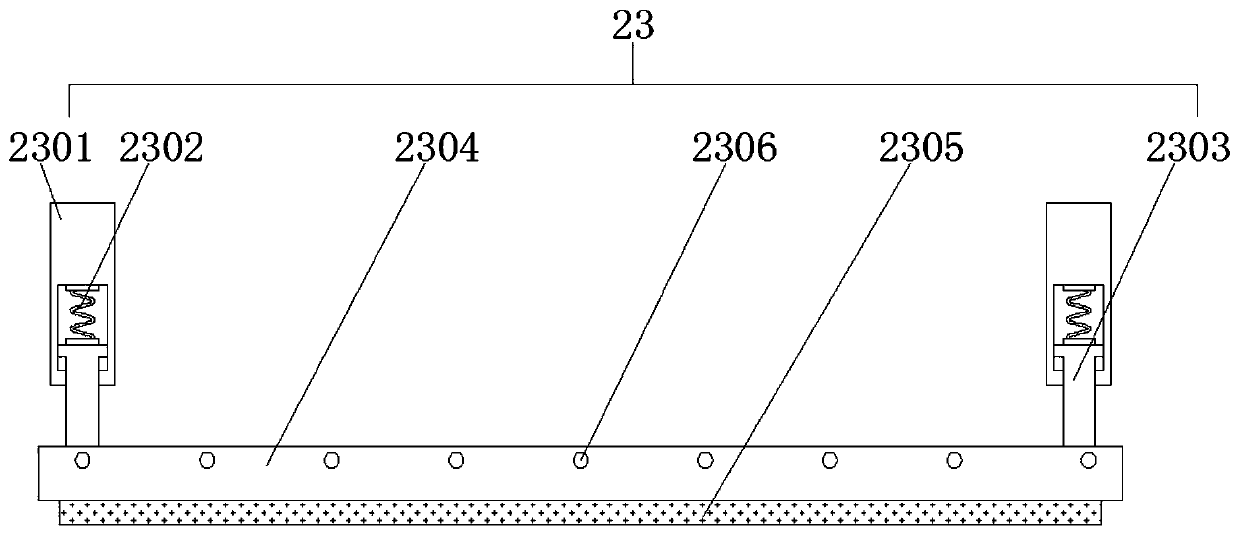

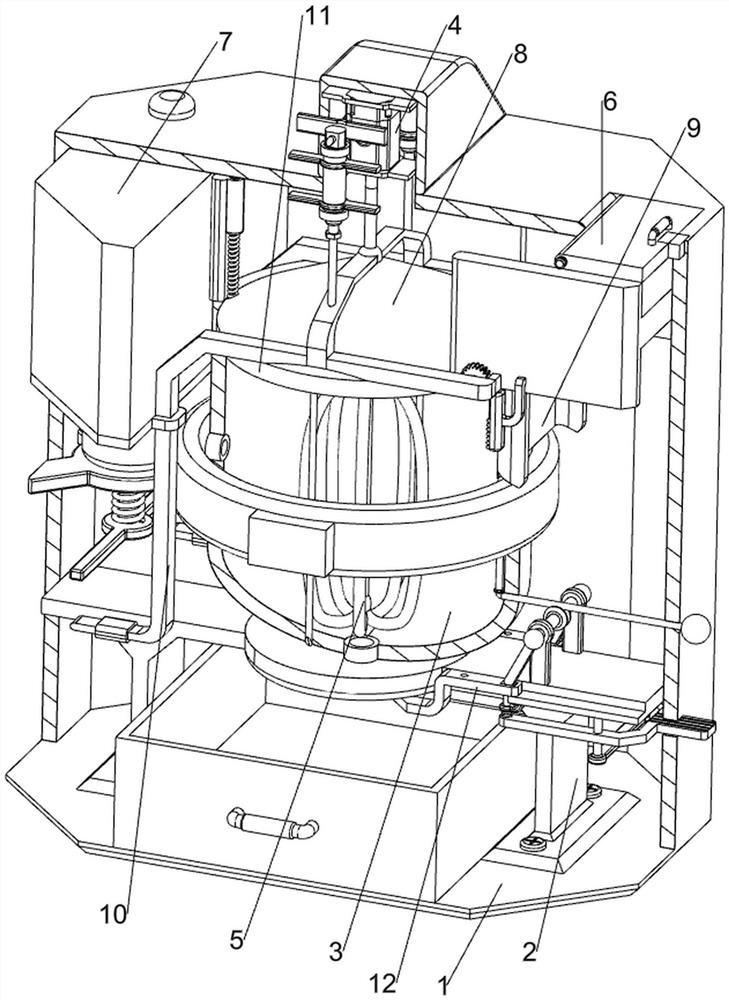

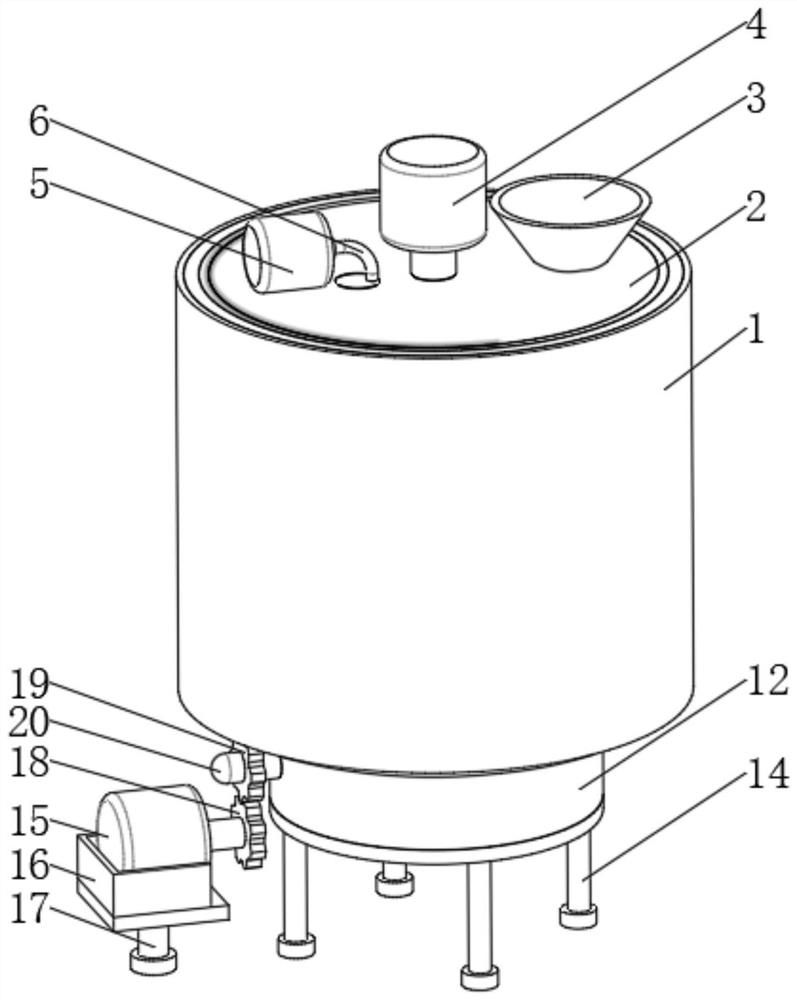

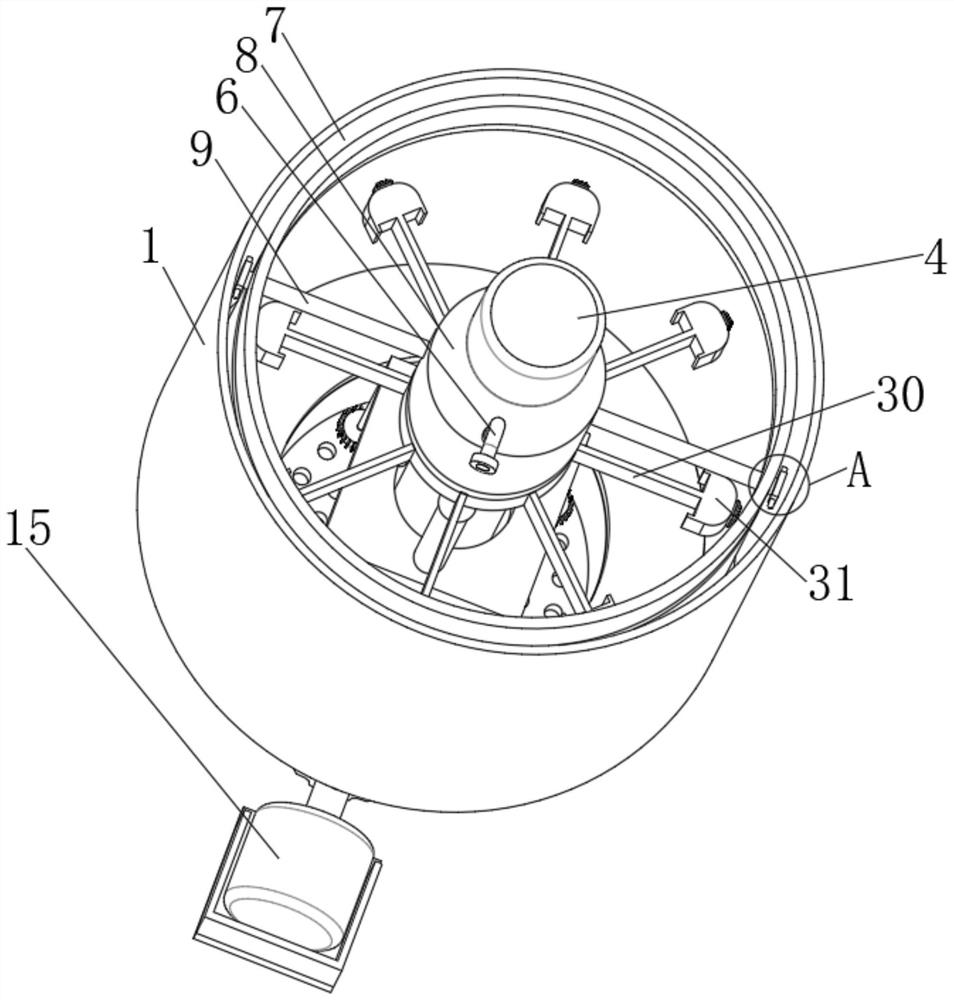

Uniform dispersion equipment for coating production

PendingCN113877460AAvoid spillingAvoid wasting resourcesRotary stirring mixersTransportation and packagingMechanical engineeringIndustrial engineering

The invention relates to dispersion equipment, in particular to uniform dispersion equipment for coating production. The technical problem to be solved by the invention is to provide the uniform dispersion equipment for coating production, which can automatically add raw materials and has a scraping effect. The uniform dispersion equipment for coating production comprises: a shell; supports which are symmetrically arranged on the lower side of the interior of the shell; a placing tank which is arranged between the inner side of the upper part of the bracket and the inner side of the shell; a servo motor which is arranged in the middle of the upper side in the shell; and a stirring paddle which is arranged on an output shaft of the servo motor, wherein the lower side of the stirring paddle is located on the inner side of the placing tank. When the raw materials are placed in the storage tank, people repeatedly pull a pull rope, and under the action of the elastic force of a third spring, a material scraping ring moves up and down to downwards scrape the raw materials adhered in the storage tank, so that the material scraping effect is achieved, waste is avoided, and the workload of workers is effectively reduced.

Owner:江西亿彩涂料股份有限公司

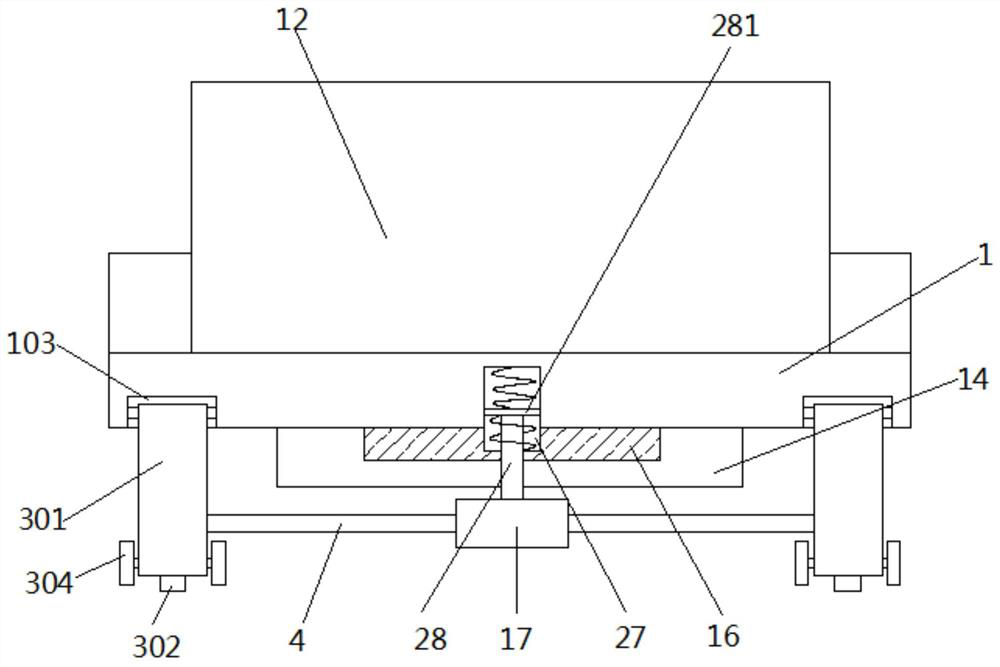

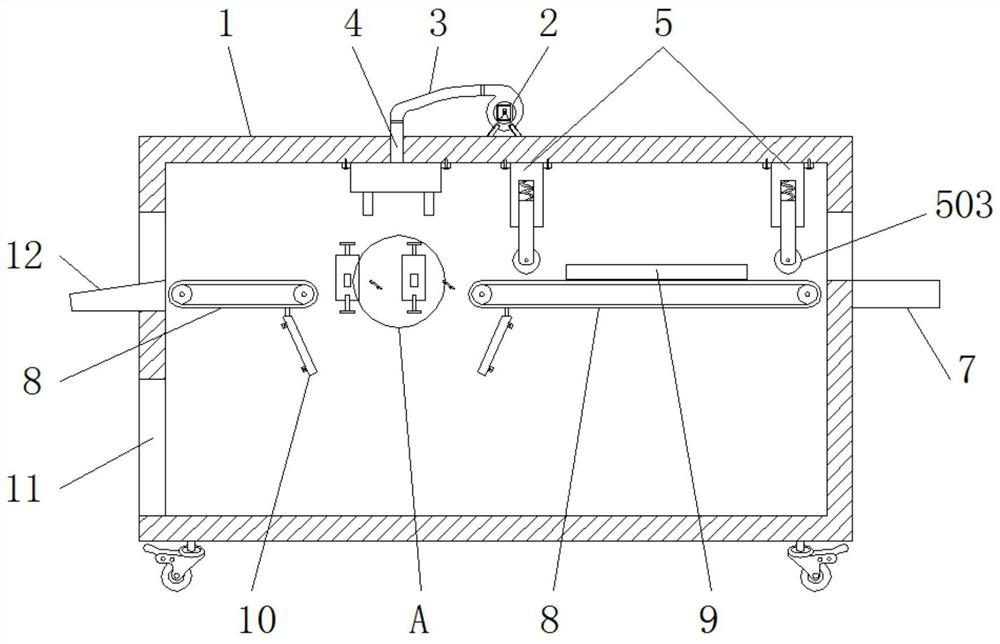

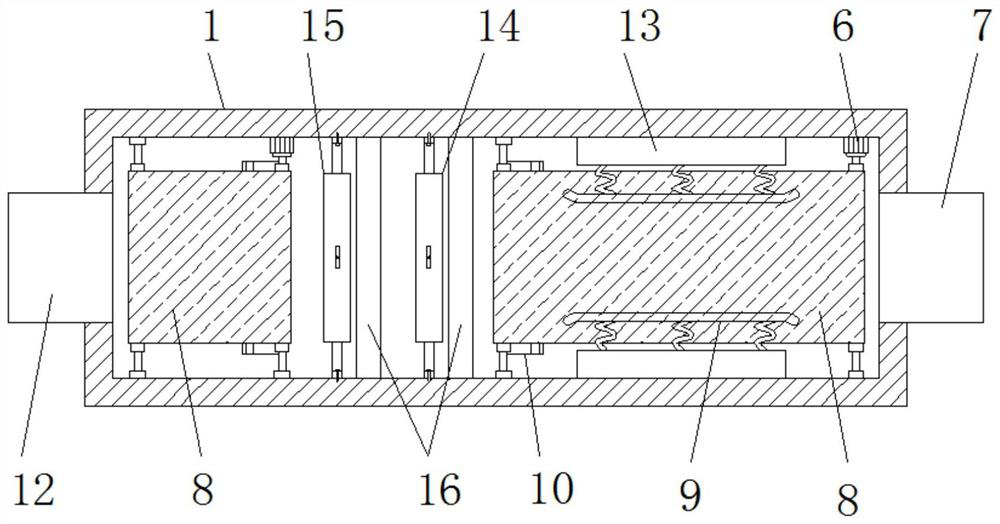

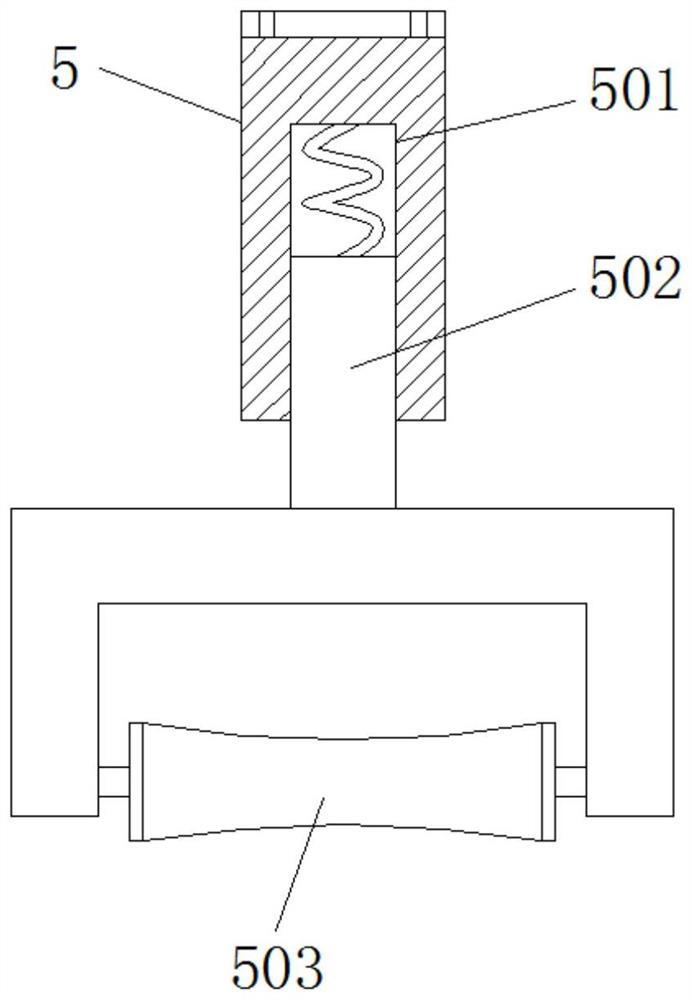

Hull rust removal and paint spraying device

ActiveCN111644285AStir wellPlay the role of scrapingGrinding drivesSpraying apparatusStructural engineeringDISC assembly

The invention provides a hull rust removal and paint spraying device. The device comprises a base, a first moving assembly, a second moving assembly, a central shaft, an H-support, a paint spraying assembly and a grinding disc assembly, wherein baffles are fixedly connected to the front and rear sides of the top of the base, a battery is fixedly connected between the baffles and on the right sideof the top of the base, the H-shaped support is arranged between the left sides of the baffles in an adapting mode, the left side of the H-shaped support is fixedly connected with the paint spraying assembly, first electric push rods are fixedly connected to the front end and the rear end of the center position of the left side of the top of the base, the top telescopic ends of the first electricpush rods are fixedly connected with the bottom of a central connecting rod of the H-shaped support, the first electric push rods are electrically connected with the battery, the center of a sliding rod is fixedly connected with a partition plate, the parts, located on the left side and the right side of the partition plate, of the sliding rod are provided with sliding blocks in a sleeve mode, anda spring is arranged at the upper end of the sliding rod and between the sliding block and the partition plate in a sleeve mode. The hull rust removal and paint spraying device solves the problem that the labor intensity of manual rust removal and paint spraying of a hull is high, an environment is polluted, and the working efficiency of an existing paint spraying device is caused low due to thefact that the device is prone to blocking.

Owner:刘伦宇

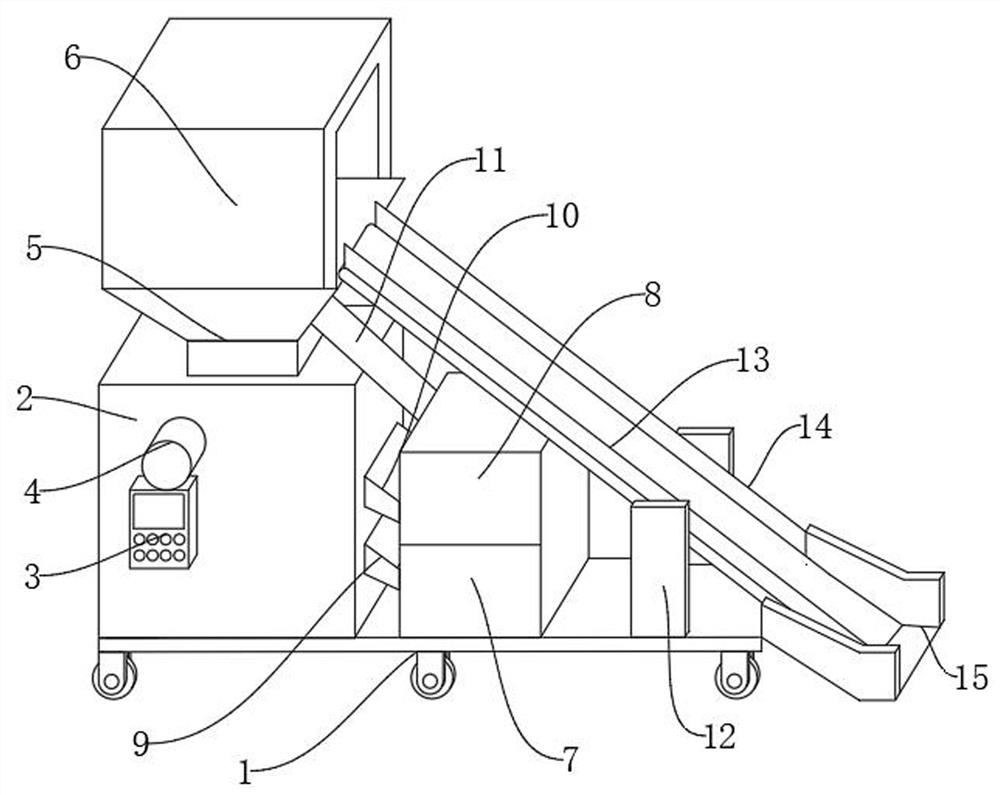

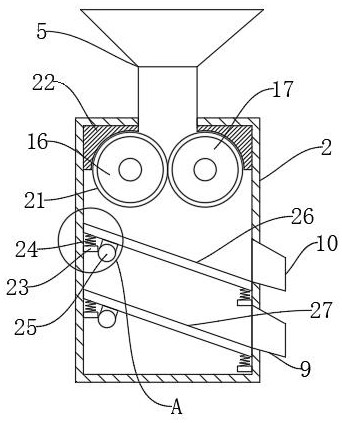

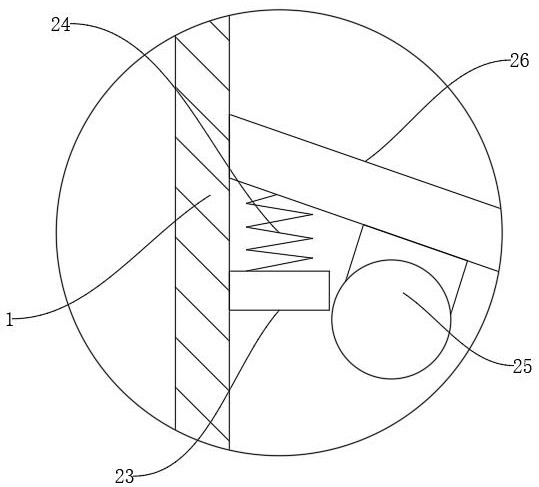

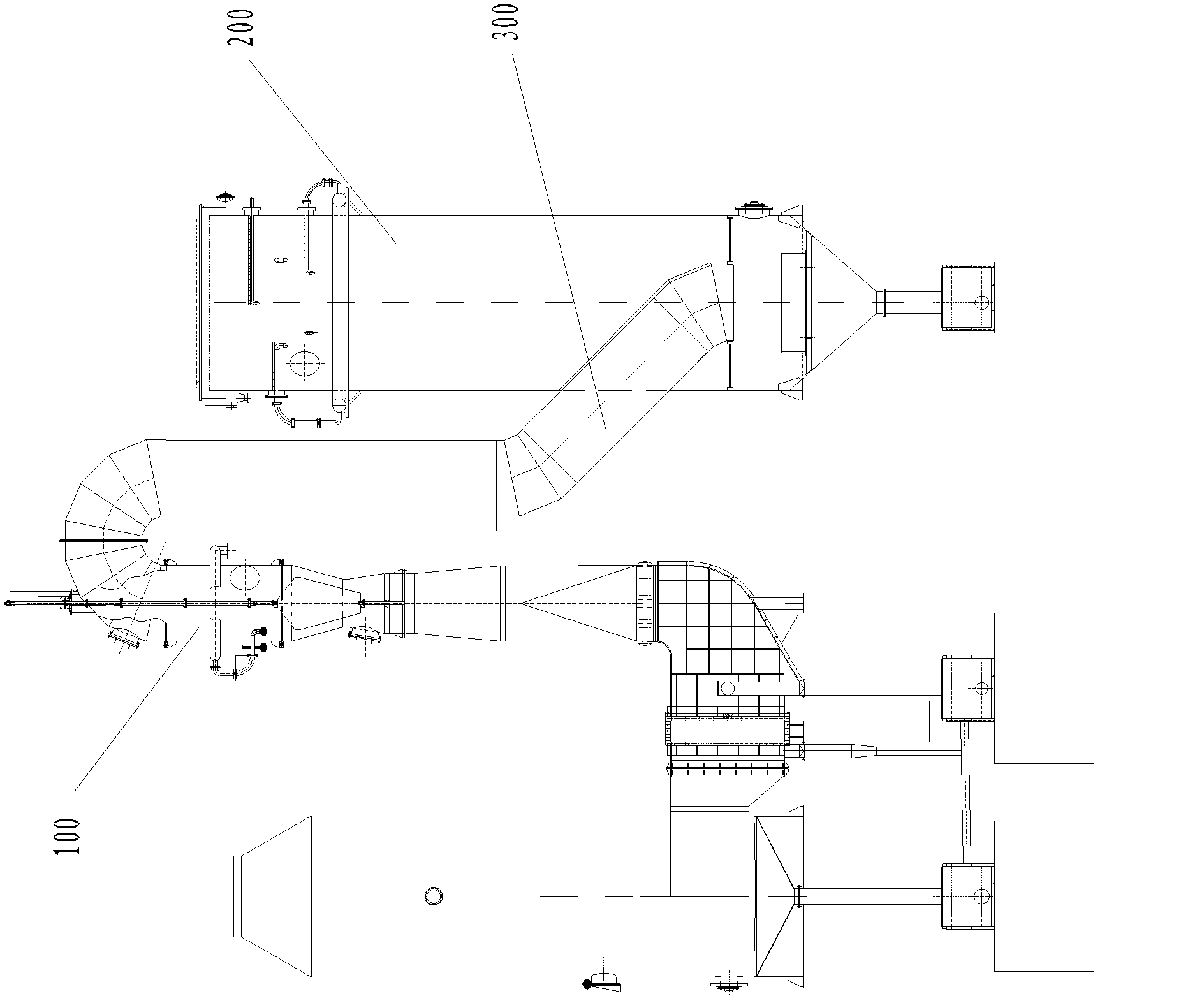

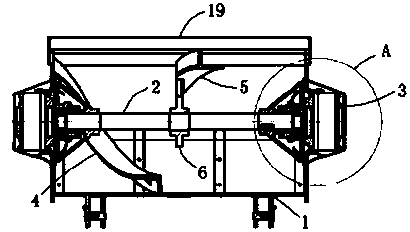

Construction waste collecting, circular crushing, screening and discharging equipment for construction engineering

InactiveCN112090494ARealize automatic cycle crushing operationIncrease the level of detailSievingScreeningArchitectural engineeringStructural engineering

The invention discloses construction waste collecting, circular crushing, screening and discharging equipment for construction engineering and belongs to the field of construction engineering. The equipment comprises a power vehicle body and a telescopic conveyor belt, wherein a crushing and screening box body is connected to one side above the power vehicle body through a screw, a feeding hopperis welded to the middle of the top end of the crushing and screening box body, the side, located above the crushing and screening box body, of the power vehicle body is connected to a screening and collecting box through a screw, a reflux box body is connected above the screening and collecting box through a screw, and a spiral conveyor is arranged between the reflux box body and the feeding hopper is arranged, so that an automatic circular crushing operation on a construction material can be achieved, and therefore, the crushing fine degree and the crushing efficiency are improved effectively. By arranging a stripper plate to guide crushing of the construction material, the material is prevented from falling off from two sides of a crushing wheel I and a crushing wheel II, and meanwhile,the stripper plate plays a role of scraping the material to scrape the construction material bonded to the crushing wheel I and the crushing wheel II.

Owner:唐翠华

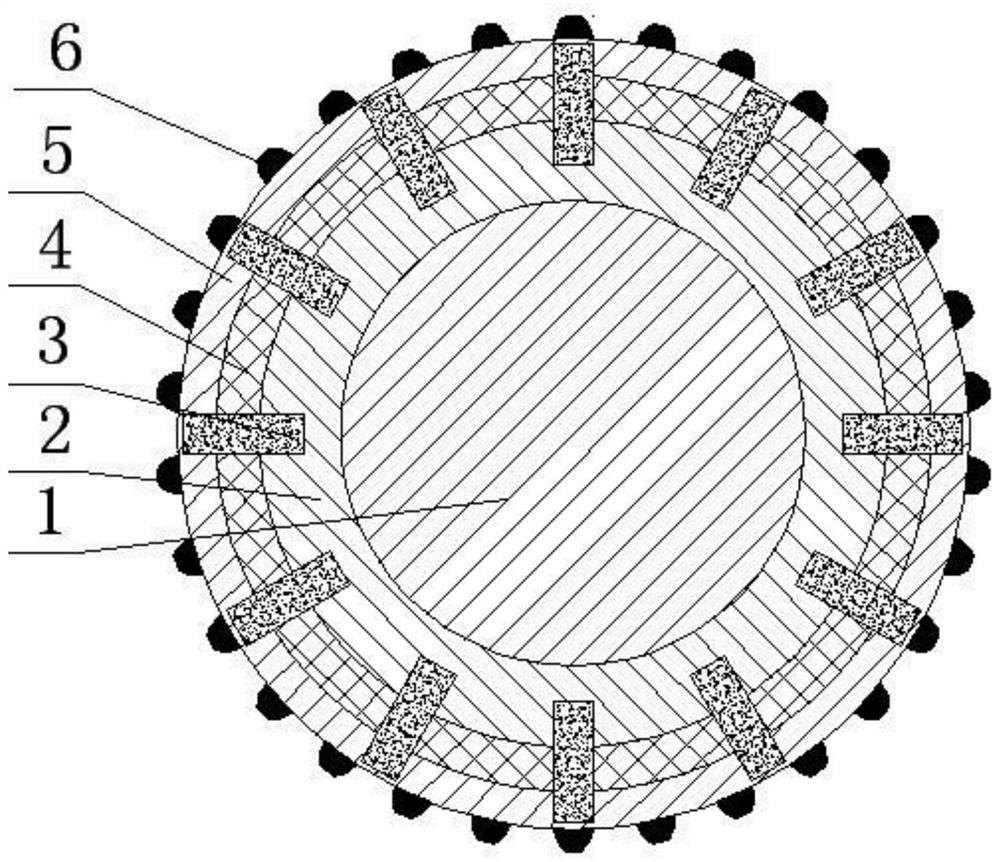

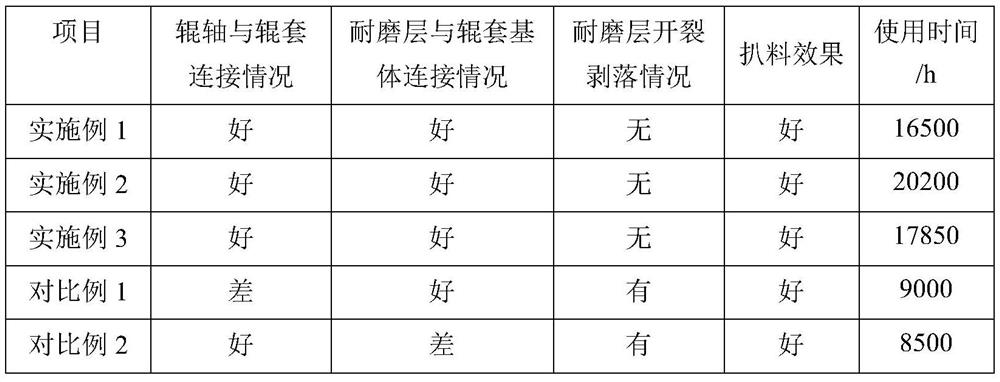

Preparation method of wear-resistant extrusion roller

PendingCN113926994AReduce the hazards of stress concentrationNot easy to crackFoundry mouldsFurnace typesBonding strengthManufacturing engineering

The invention belongs to the field of preparation of industrial crushing machinery, and provides a preparation method of a wear-resistant extrusion roller. The method comprises the steps of cavity preparation, wear-resistant stud placement, mother liquid pouring, heat treatment, inner hole machining, hot charging, transition layer surfacing, wear-resistant layer surfacing and pattern surfacing. Steel-bonded alloy wear-resistant studs have good impact resistance, wear resistance and weldability, stress concentration can be reduced, a base body does not easily crack, the skeleton supporting effect is achieved, and a transition layer and a wear-resistant layer are not peeled off in a large area; the transition layer improves the weldability of a roller sleeve base body, enhances the metallurgical bonding strength of the wear-resistant layer and the roller sleeve base body, and reduces the crack generation tendency; before surfacing of the transition layer, the wear-resistant layer and wear-resistant patterns, a roll shaft and a roll sleeve are subjected to hot charging so that the phenomena that the roll shaft and the roll sleeve are not firmly connected and the wear-resistant layer and the wear-resistant patterns are easily peeled off due to hot charging after welding are changed; and the service life of the wear-resistant extrusion roller prepared by the method is prolonged by more than one time compared with that of the extrusion roller with a conventional structure.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

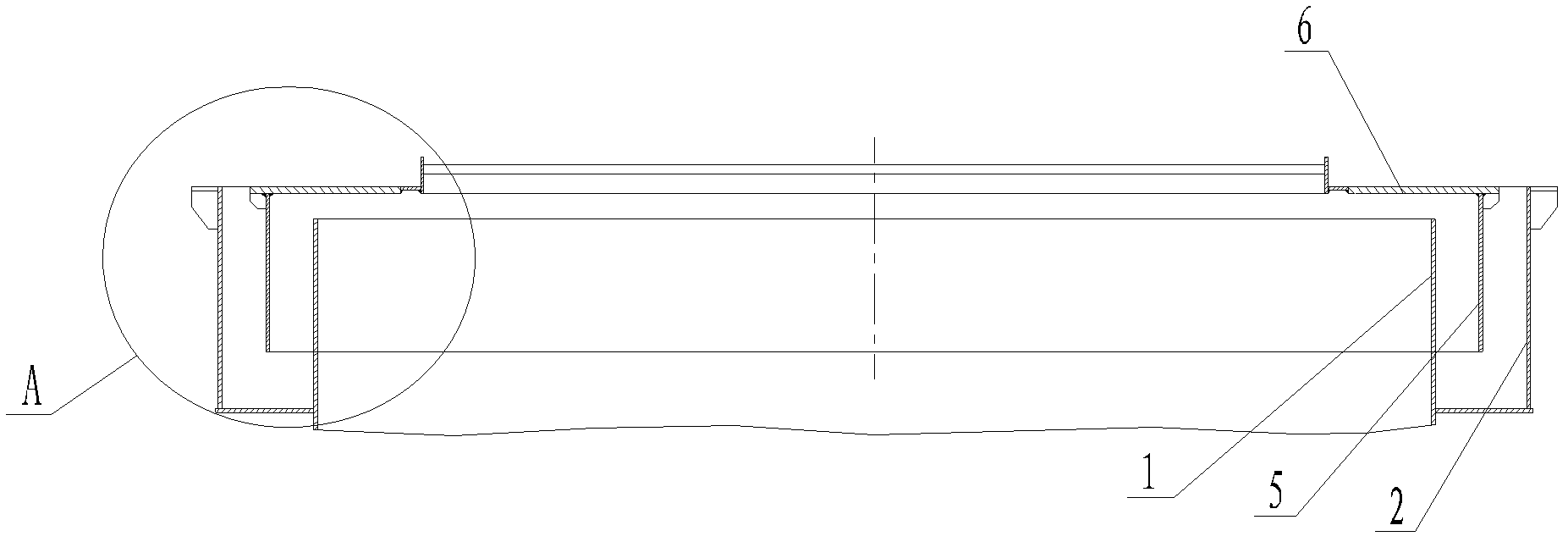

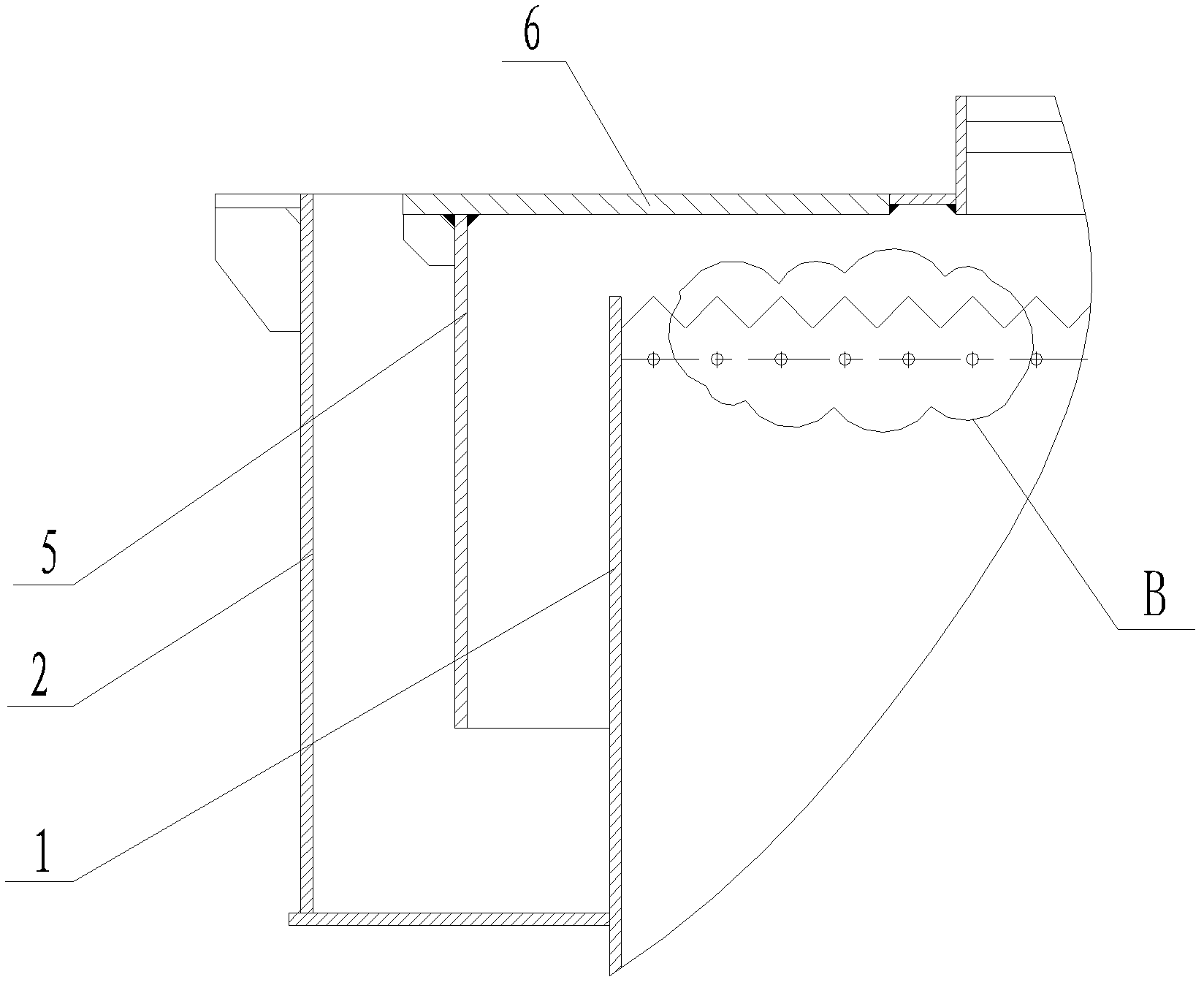

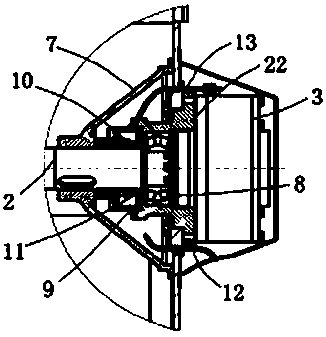

Silk screen roller mechanism of rotary screen printing machine

ActiveCN113103744AImprove cleanlinessEffect of wettingScreen printersPrinting press partsPolymer scienceEngineering

The invention relates to the technical field of printing, and discloses a silk screen roller mechanism of a rotary silk screen printing machine. The silk screen roller mechanism comprises a silk screen roller, a rotary shaft core roller is arranged in the silk screen roller, an ink cavity and a liquid cavity are formed in the shaft core roller, the ink cavity and the liquid cavity are both coaxially formed with the shaft core roller, and a heating plate located between the ink cavity and the liquid cavity is arranged in the shaft core roller. According to the silk screen roller mechanism, flushing liquid is continuously conveyed into an inner liquid pressing tank and an outer liquid collecting tank, and the residue removing effect is improved; besides, the effect of infiltrating printing ink which cannot be removed is achieved, and the situation that the printing ink is used in a traditional printing machine to keep the silk screen roller infiltrated is avoided, so that the loss of the printing ink is reduced, and the printing cost is reduced; and in addition, the problem that meshes of the silk screen roller are blocked due to drying and caking of ink which cannot be removed on the surface of the silk screen roller can be relieved, and the purposes of prolonging the service life of the silk screen roller and improving the printing quality can be achieved.

Owner:广州盛雅图玻璃工艺有限公司

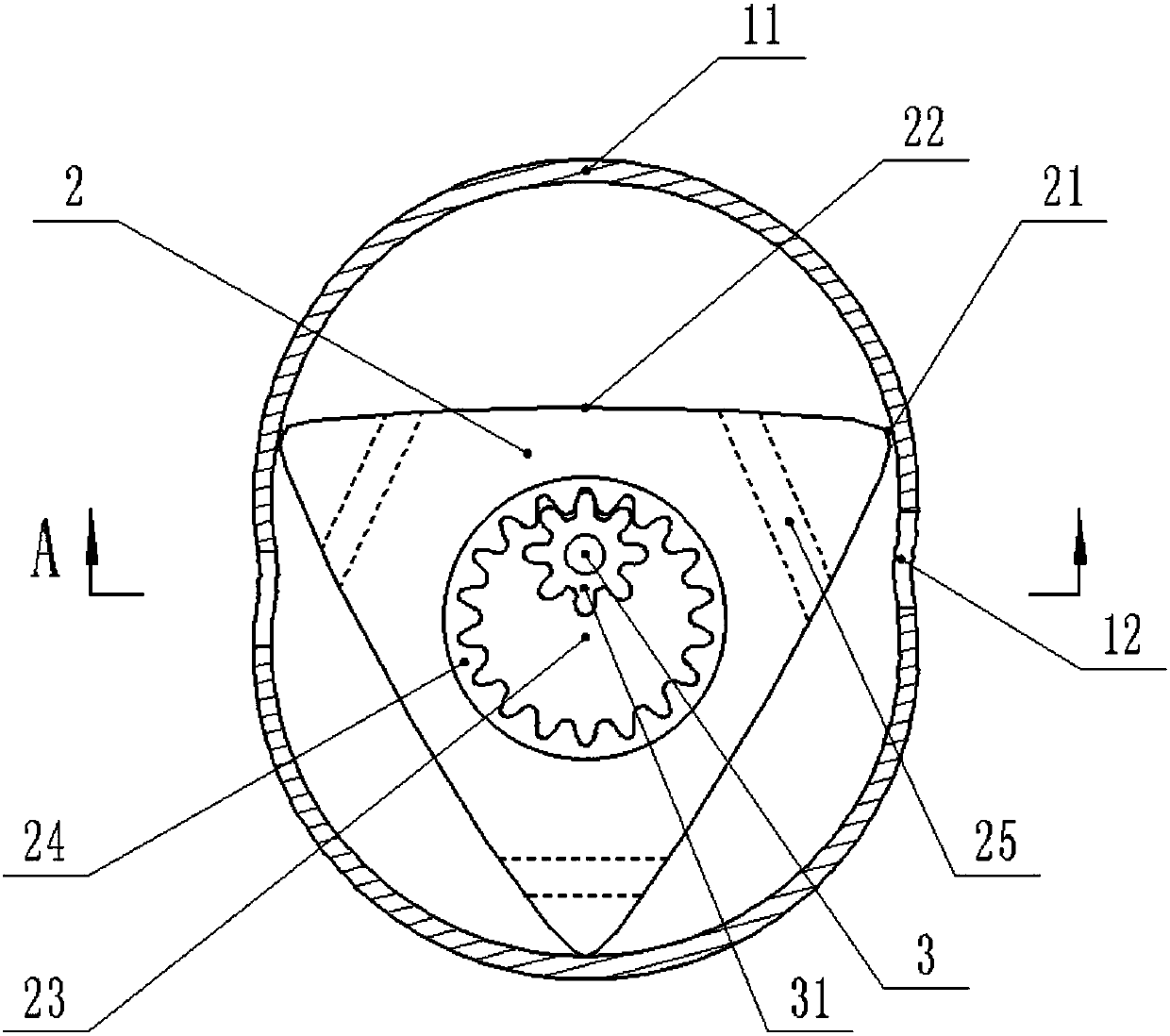

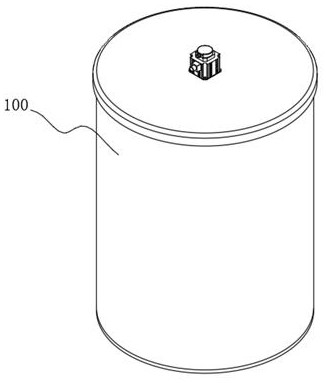

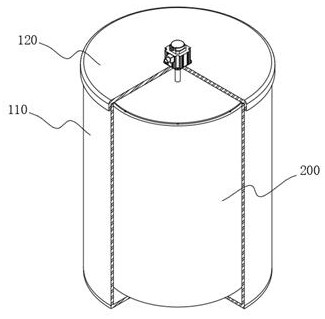

Mortar stirring cylinder

InactiveCN107899498AWell mixedAvoid cleaning difficultiesTransportation and packagingMixer accessoriesTriangular prismMixing effect

The invention relates to the technical field of mortar stirring equipment and particularly discloses a mortar stirring cylinder, comprising a cylinder body, a triangular rotor and a spindle; the cylinder body is a cycloidal cylinder body, the top wall of the cylinder body is a flat top, the bottom wall of the cylinder body is a flat bottom, the sidewall of the cylinder body is in figure-eight shape, the sidewall of the cylinder body includes two arc portions and two thin-waist portions, a discharge pipe is communicated with the thin-waist portions, the cylinder body is provided with a first through hole that is arranged in the center of the cylinder body, and the triangular rotor is in triangular prism shape, is positioned in the cylinder body and is rotationally connected with the cylinder body. The invention is intended to solve the problems that the stirring cylinder of an existing mortar tank is poor in mixing effect and mortar may consolidate on the inner wall of the cylinder body.

Owner:CHONGQING RUIXUAN HAOBANG NEW BUILDING MATERIAL

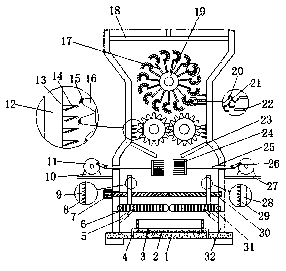

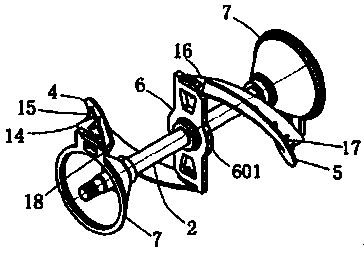

Alternanthera philoxeroides straw crushing device for river channel cleaning

ActiveCN109168640APrevent hanging onSolve feeding difficultiesFeeding-stuffCrop conditionersEngineeringAlternanthera

The invention belongs to the technical field of river channel cleaning, in particular to an alternanthera philoxeroides straw crushing device for river channel cleaning. Aiming at the problem that alternanthera philoxeroides straws are intertwined easily and difficult to feed, the following scheme is proposed: the device includes a base; the base is provided with supporting legs in the four corners of the top outer wall thereof, the same box body is arranged on the top outer walls of the four supporting legs; the box body is provided with a feeding inlet in the top outer wall thereof; the boxbody is provided with a first through hole and a first groove in two inner walls near the feeding inlet respectively; and the inner walls of the first through hole and the first groove are rotationally connected with a feeding wheel through bearings. The feeding wheel can be driven to rotate by a first rotating motor. Through a feeding hook and barbs, alternanthera philoxeroides straws can be hooked and fed to crushing rollers. Baffles can prevent the straws from being hooked to the feeding hook. Therefore, the problem that the alternanthera philoxeroides straws are intertwined easily and difficult to feed can be solved.

Owner:嘉兴麦瑞网络科技有限公司

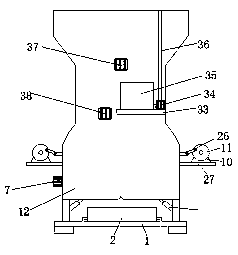

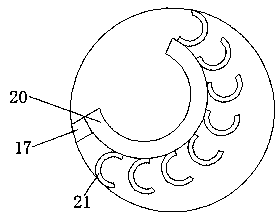

One-time dust removal system for revolving furnace

ActiveCN103184307AAvoid local overheatingSolve the strength problemManufacturing convertersIncreasing energy efficiencyCooling towerFlue gas

The invention discloses a one-time dust removal system for a revolving furnace, which comprises a fast overflow cooling tower and an adjustable venturi, wherein the lower-middle part of the fast overflow cooling tower is connected with the adjustable venturi through a connecting bend; an overflow water tank which is provided with a circular-ring-shaped cross section and surrounds the outer wall of a tower body is arranged at the upper part of the tower body of the fast overflow cooling tower; and the top end edge of the tower body is jagged. Meanwhile, a plurality of through holes in a circle are formed in the tower wall close to the top end of the tower body, and every through hole is located below every jagged tooth tip. The one-time dust removal system for revolving furnace enables water in the overflow water tank to overflow into the tower body from the top end edge of the tower body uniformly, and the threat to the strength and the normal operation of the tower body due to the partial overheating is prevented; and moreover, water in the overflow water tank flows into the inner wall in each position of the tower body through the through holes, so that a dry and wet interface is prevented from generating on the inner wall of the tower, the powder is prevented from sticking to the inner wall of the tower body, and the flowing and the heat exchange of dry flue gas are performed smoothly.

Owner:北京明诚环保科技有限公司

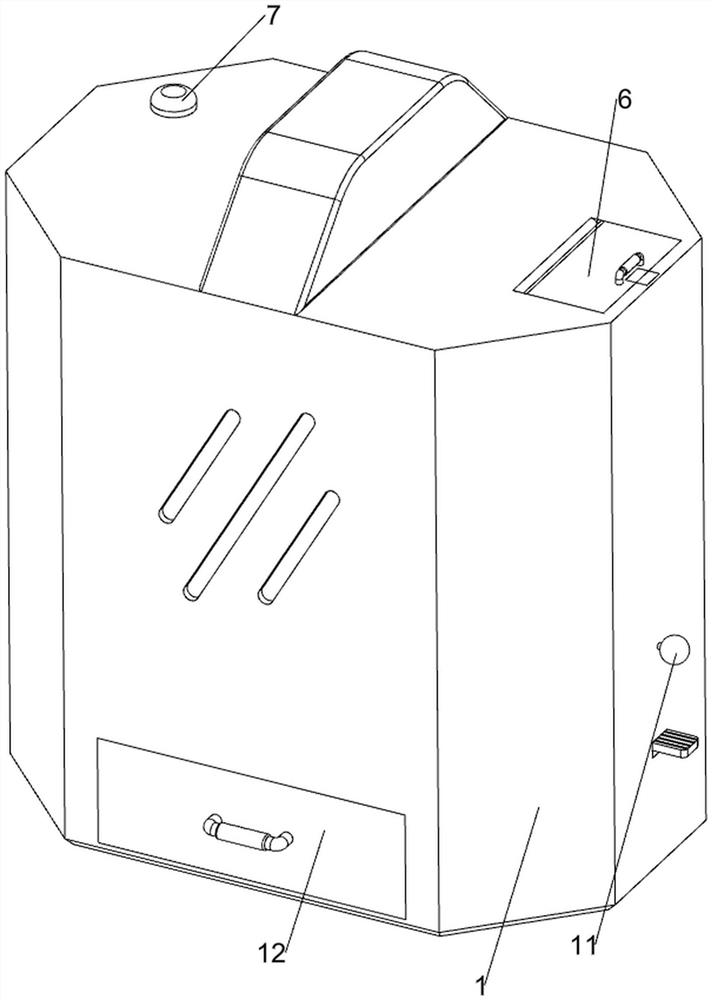

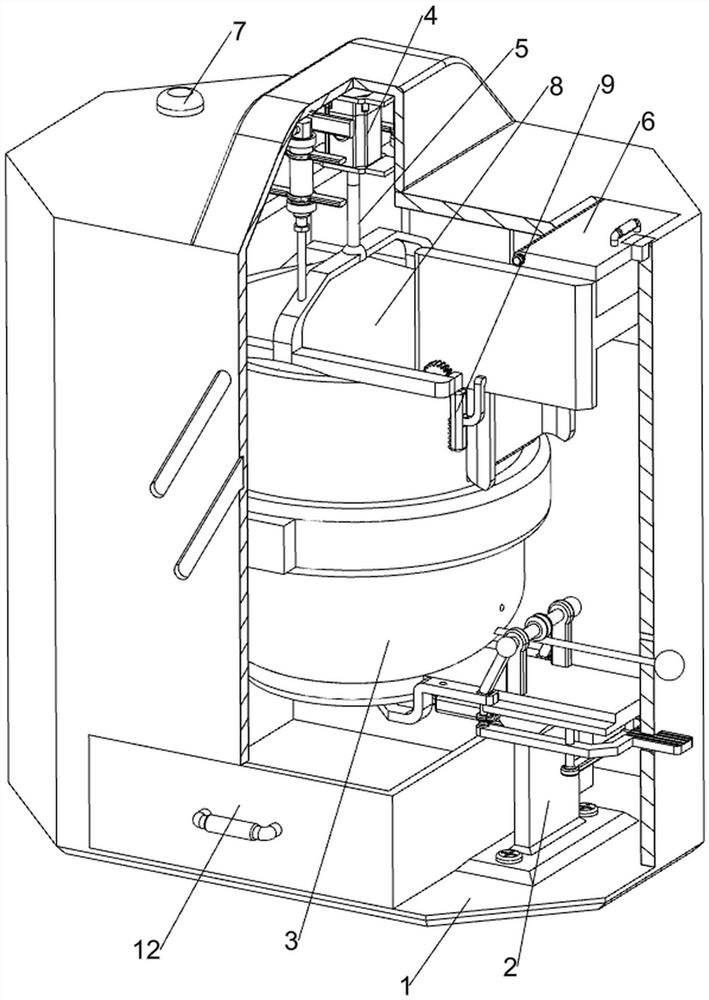

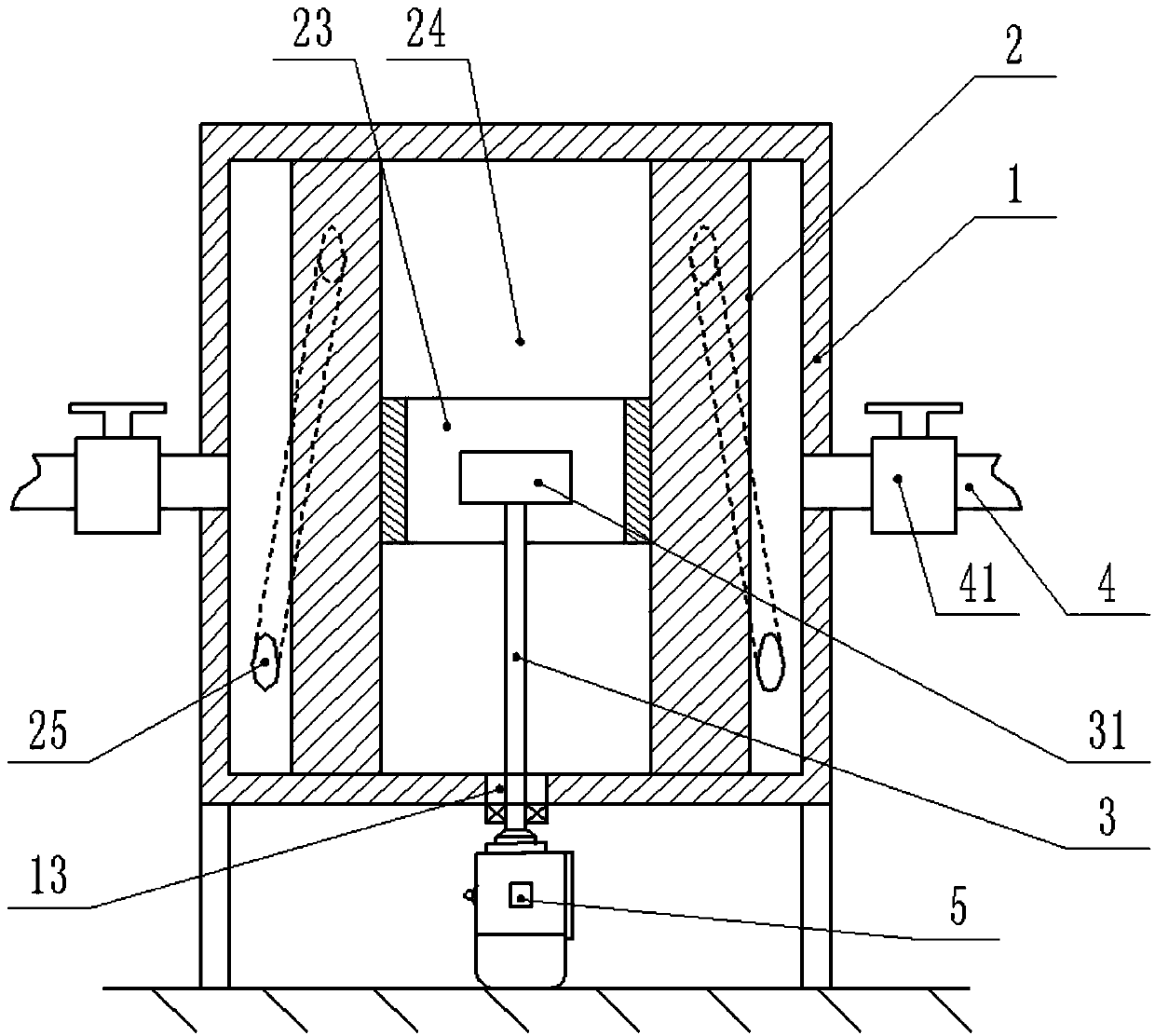

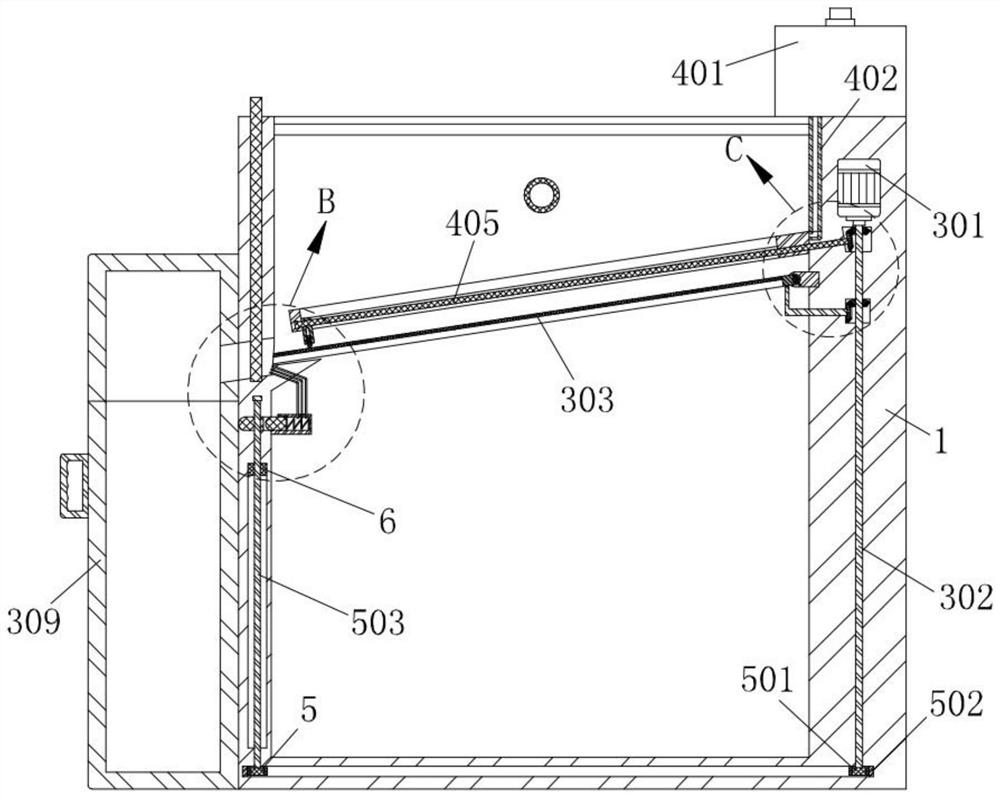

Intermittent unloading and repair device for polluted soil

InactiveCN109013691AImprove repair effectPlay the role of scrapingContaminated soil reclamationEngineeringMixing effect

The invention discloses an intermittent unloading and repair device for polluted soil. The device comprises a repair box; a rotating drum is arranged at the middle part of the repair box; multiple sets of stirring mechanisms are mounted on the rotating drum in the repair box; control plates are stretched at the outer ends of two support pipes in each set of stirring mechanisms; a mounting base ismounted at the left end of the rotating drum; the mounting base extends into the inner side of the left end of the rotating drum; an electric heating rod is mounted in the rotating drum; an U-shaped frame is mounted at the left end of the mounting base; the right end of the rotating drum is connected with a medicine liquid pipe; the medicine liquid pipe extends into the inner side of the right endof the rotating drum; a pressure pump is mounted on the medicine liquid pipe; and the other end of the medicine liquid pipe is connected to the bottom of the side surface of a medicine liquid box. The device is reasonable in structural design, can intermittently feed and discharge materials, is stable in operation and excellent in medicament feeding and mixing effect, and can efficiently heat medicaments to improve the soil repair quality.

Owner:甘灿琼

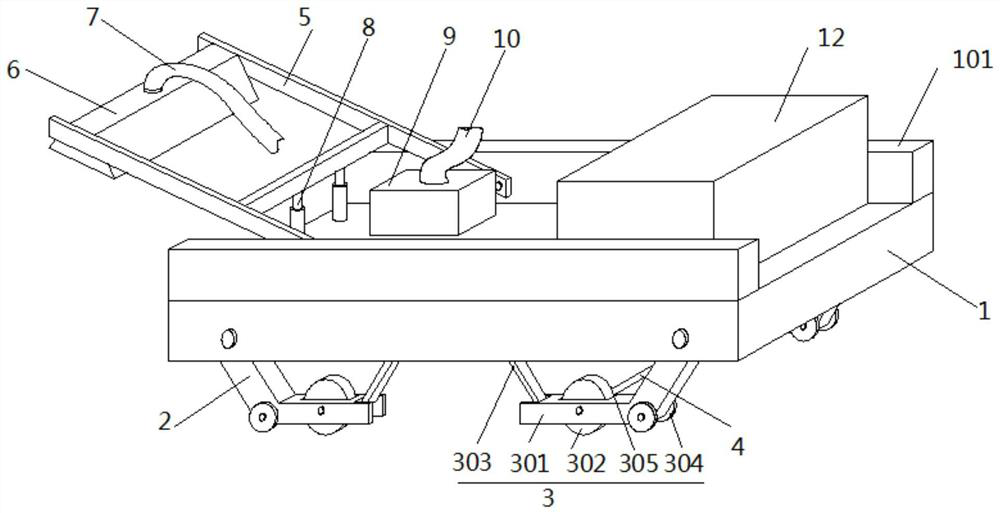

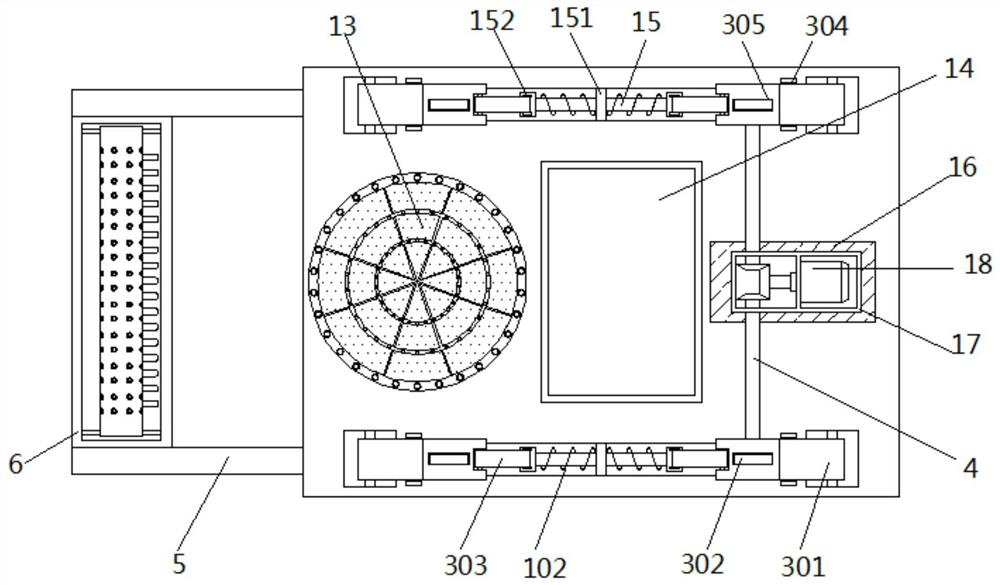

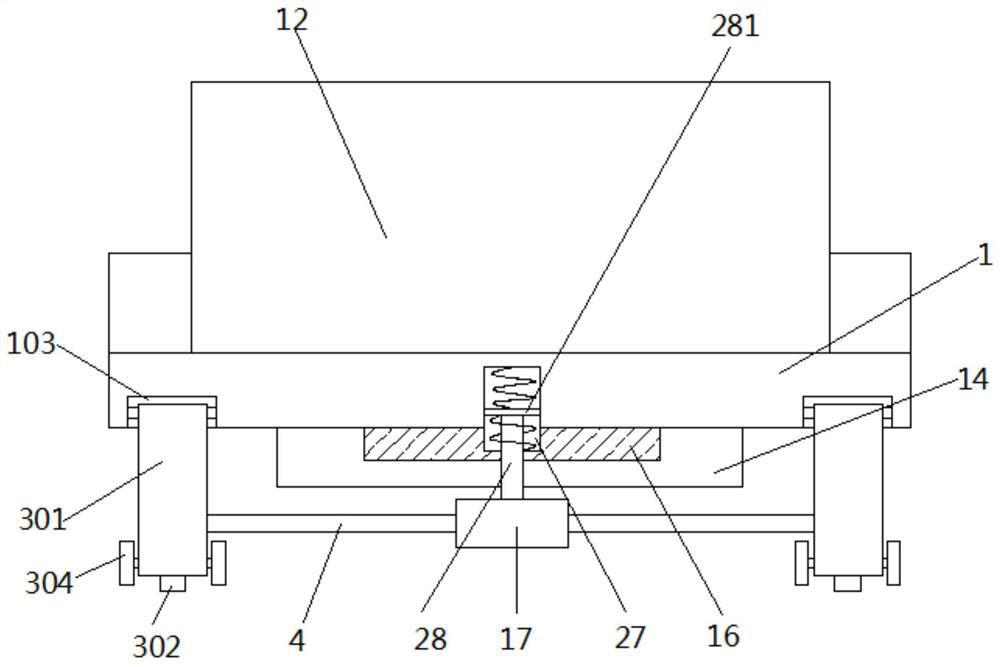

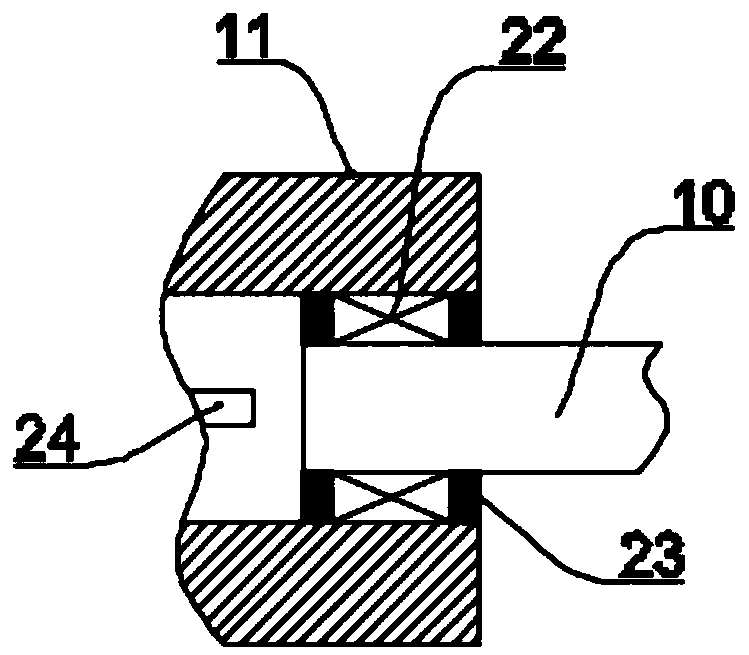

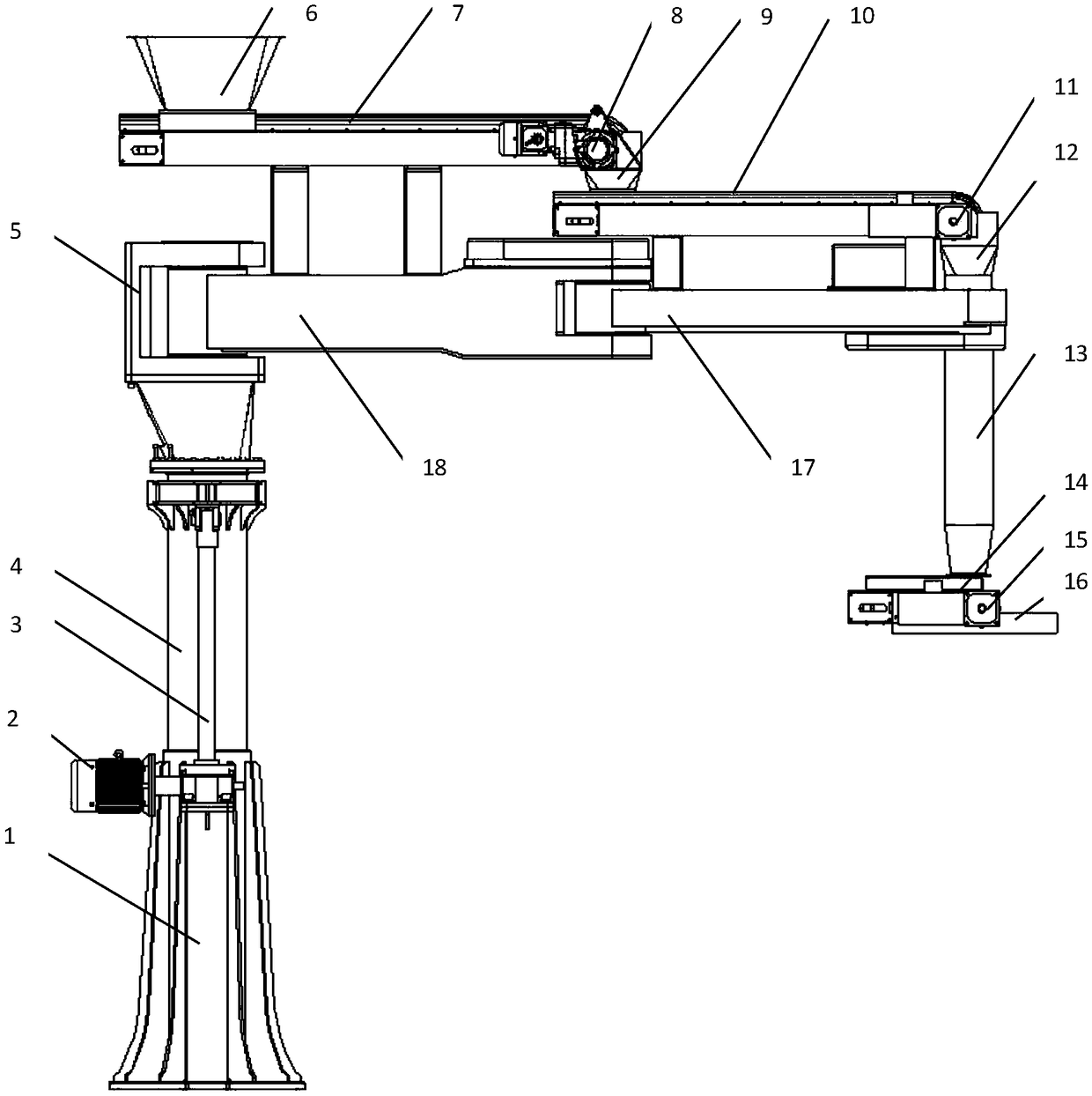

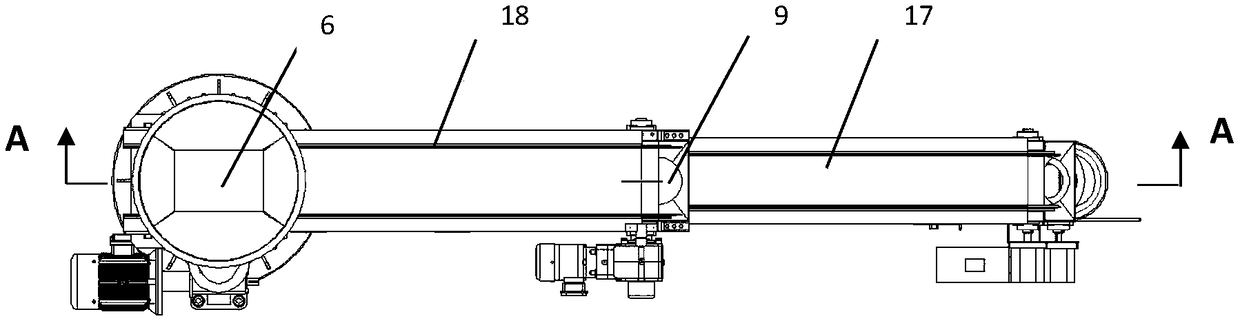

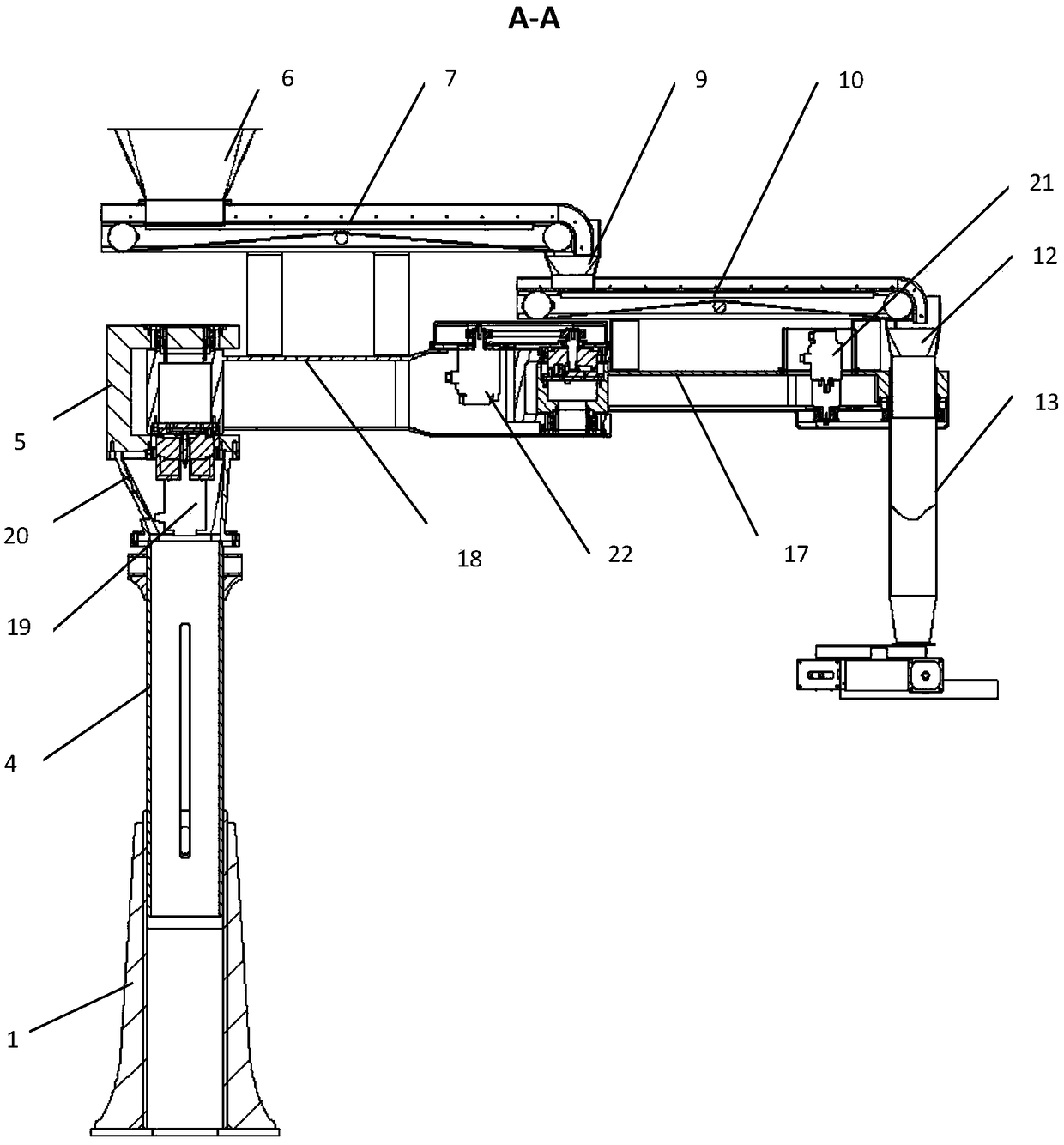

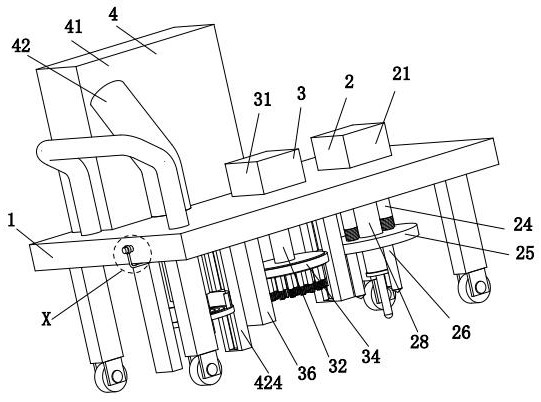

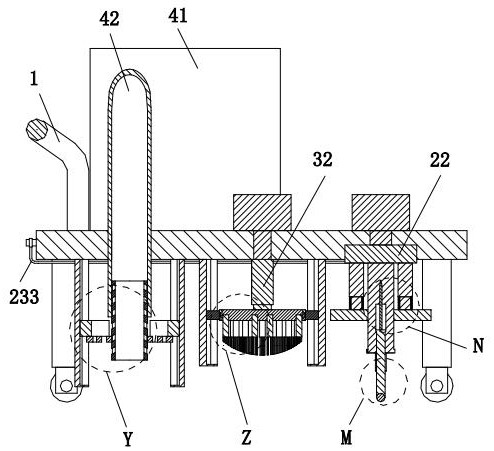

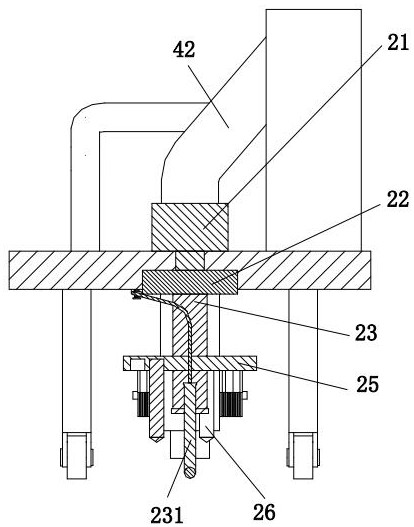

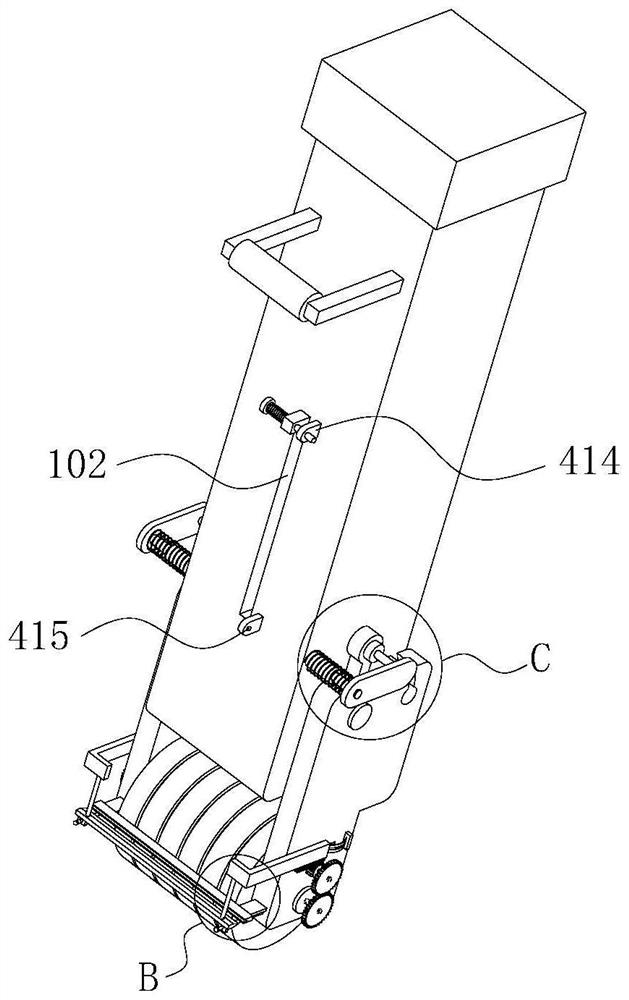

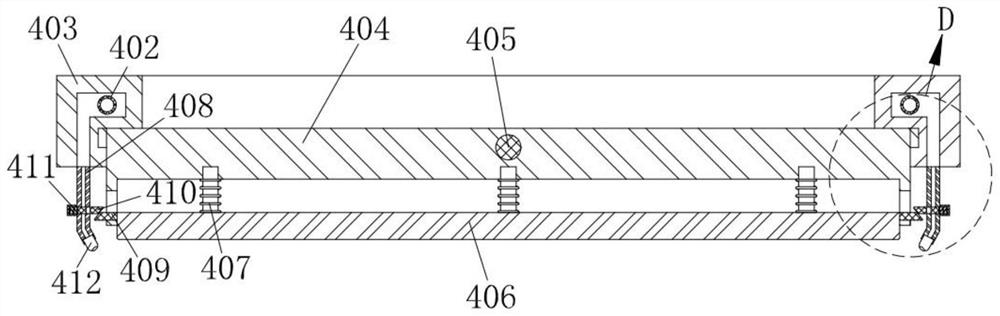

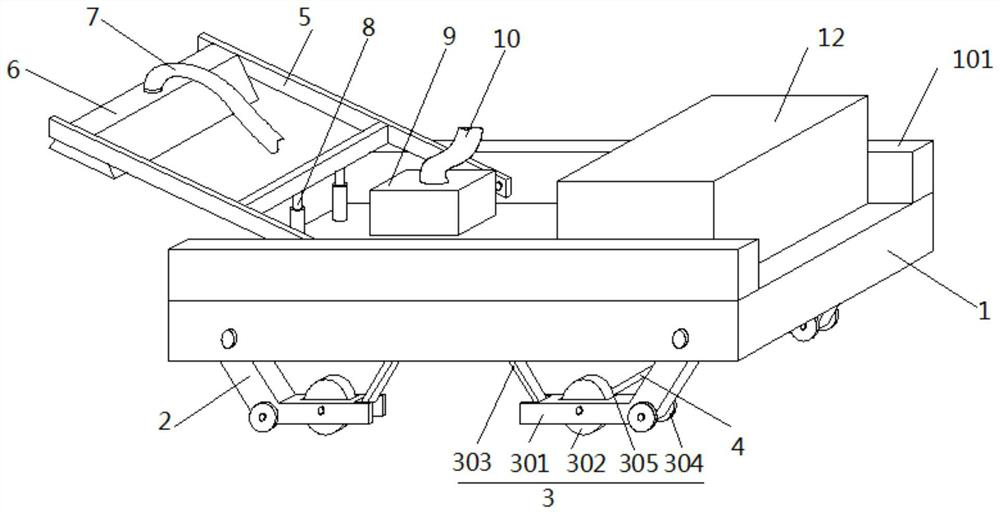

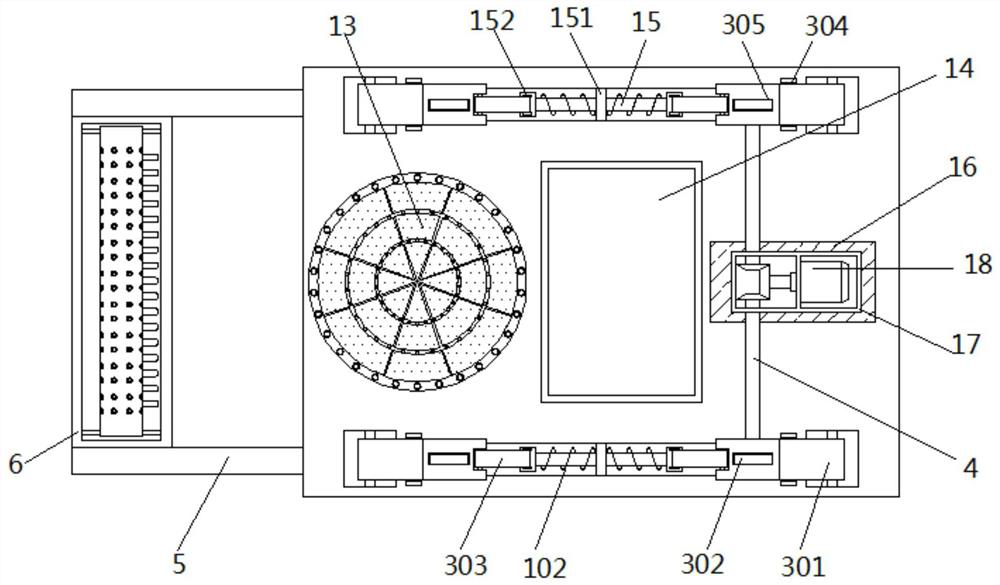

Steamer feeding robot

PendingCN109264325APlay the role of scrapingReduce momentumLoading/unloadingMechanical conveyorsMechanical engineeringSmall arms

A steamer feeding robot belongs to the technical field of wine steamer feeding equipment. The steamer feeding robot comprises a base, a lifting driving mechanism, a lifting vertical column, a large arm, a small arm, a primary conveying mechanism and a secondary conveying mechanism, wherein the base is drivingly provided with the lifting vertical column, the lifting driving mechanism is used for driving the lifting vertical column to move up and down, the top of the lifting vertical column is connected with one end of the large arm through a large arm rotating mechanism, the other end of the large arm is connected with the small arm through a small arm rotating mechanism, the primary conveying mechanism is mounted on the upper portion of the large arm, the second conveying mechanism is mounted on the upper portion of the small arm, both the first conveying mechanism and the second conveying mechanism convey materials through synchronous belts, the tail end of the primary conveying mechanism conveys material to the input end of the secondary conveying mechanism, a vertical conveying arm is arranged at the output end of the secondary conveying mechanism and is in a hollow tubular structure, and a buffering conveying mechanism is arranged at the lower end of the vertical conveying arm. The steamer feeding robot can achieve automatic steamer feeding.

Owner:ANHUI HISEED ROBOT CO LTD

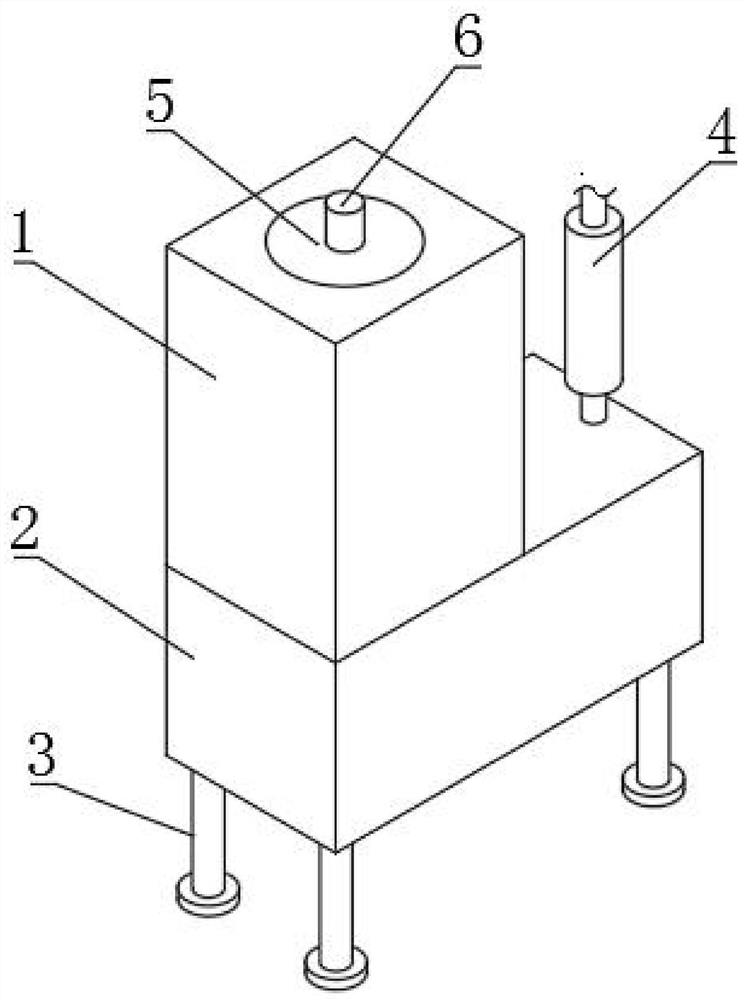

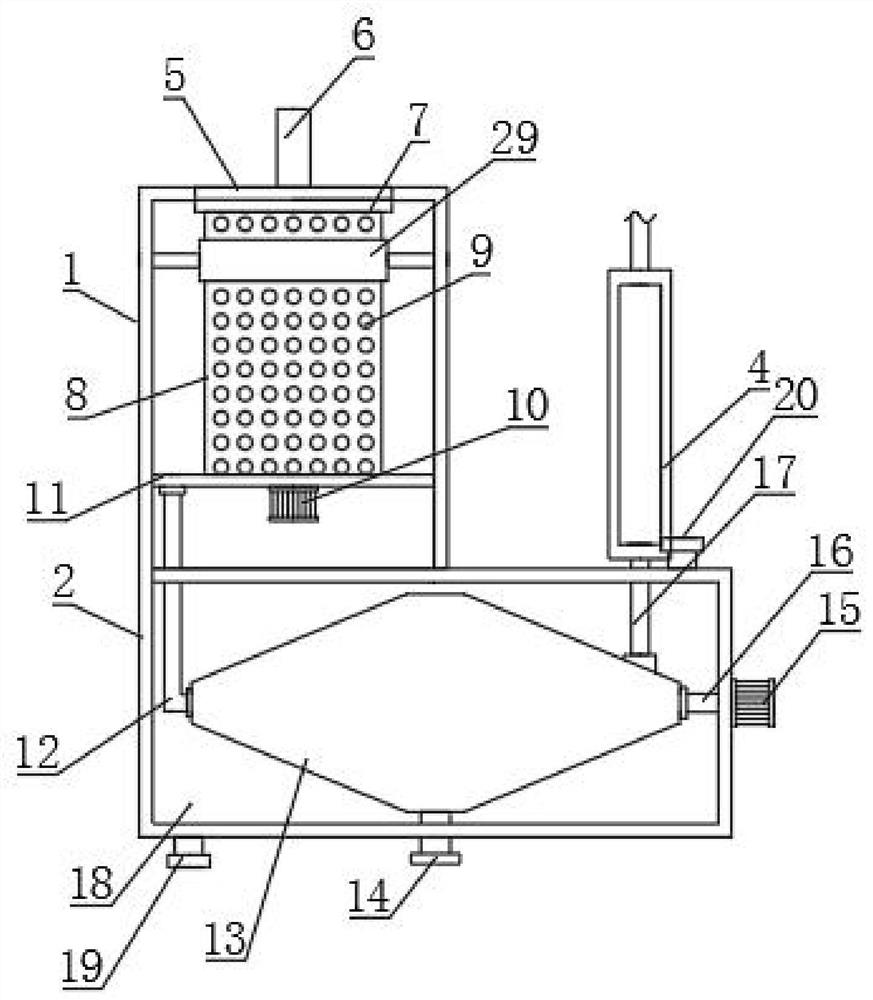

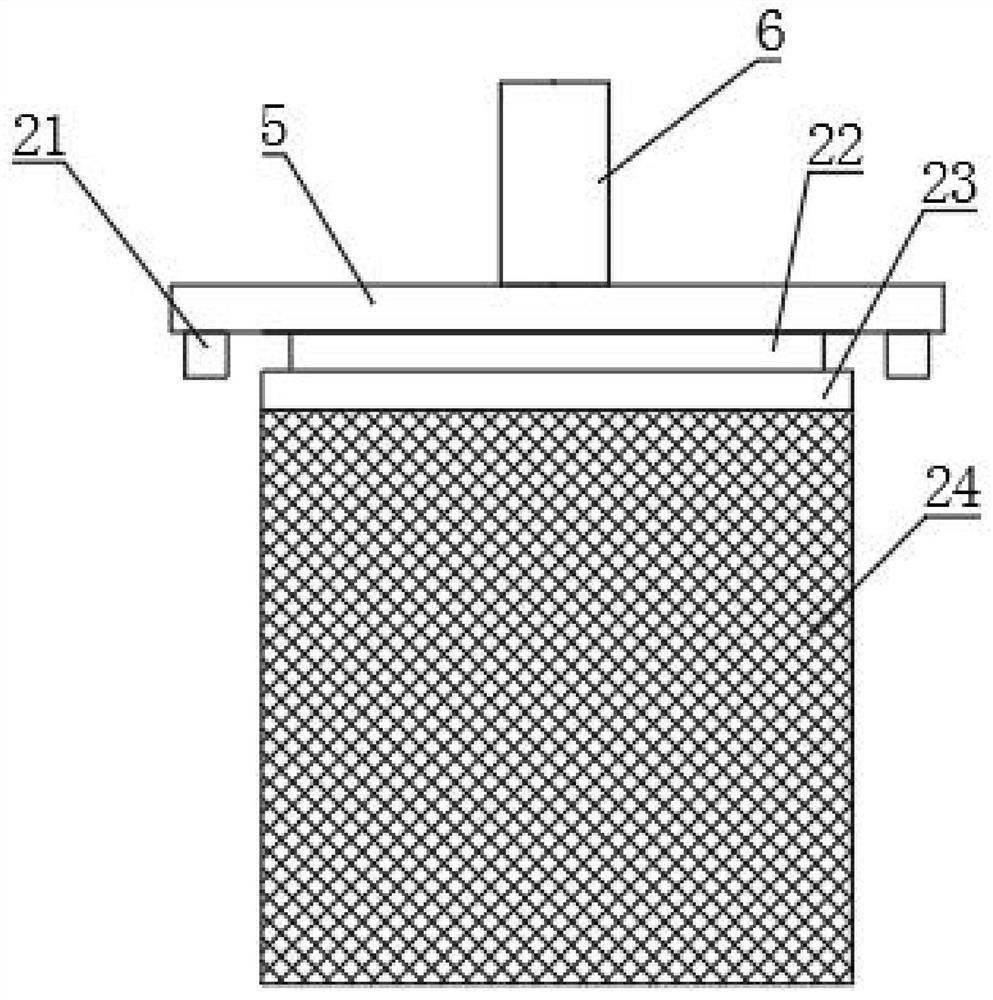

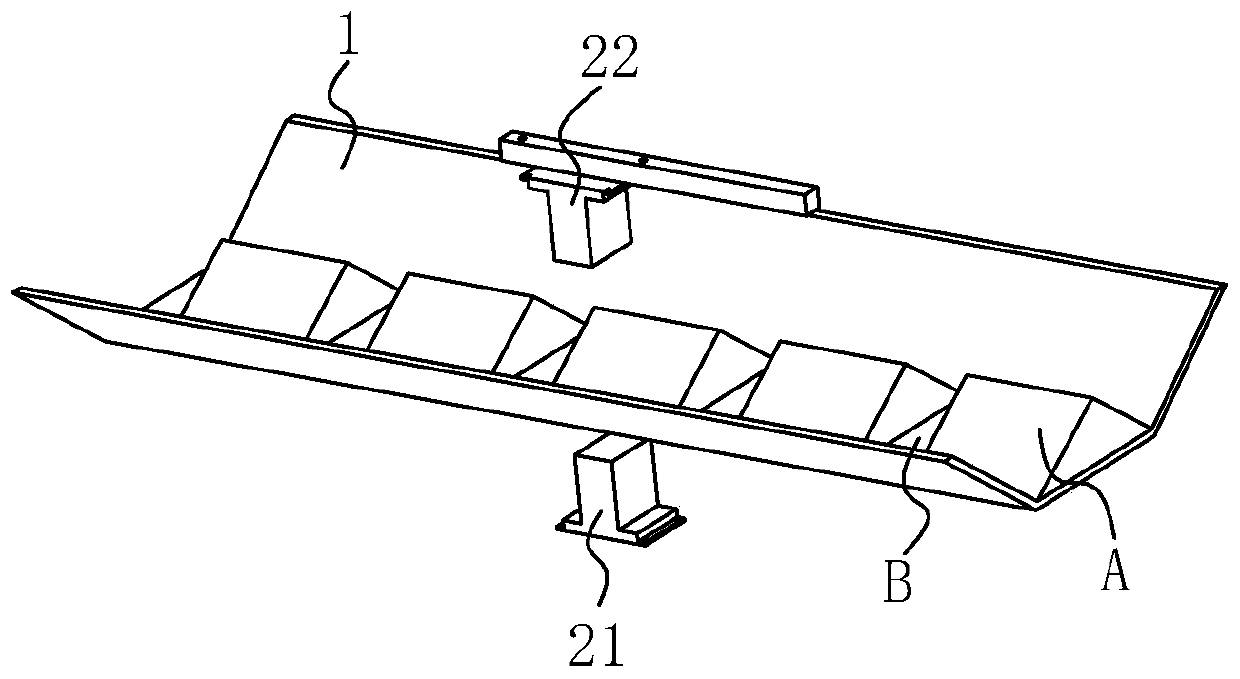

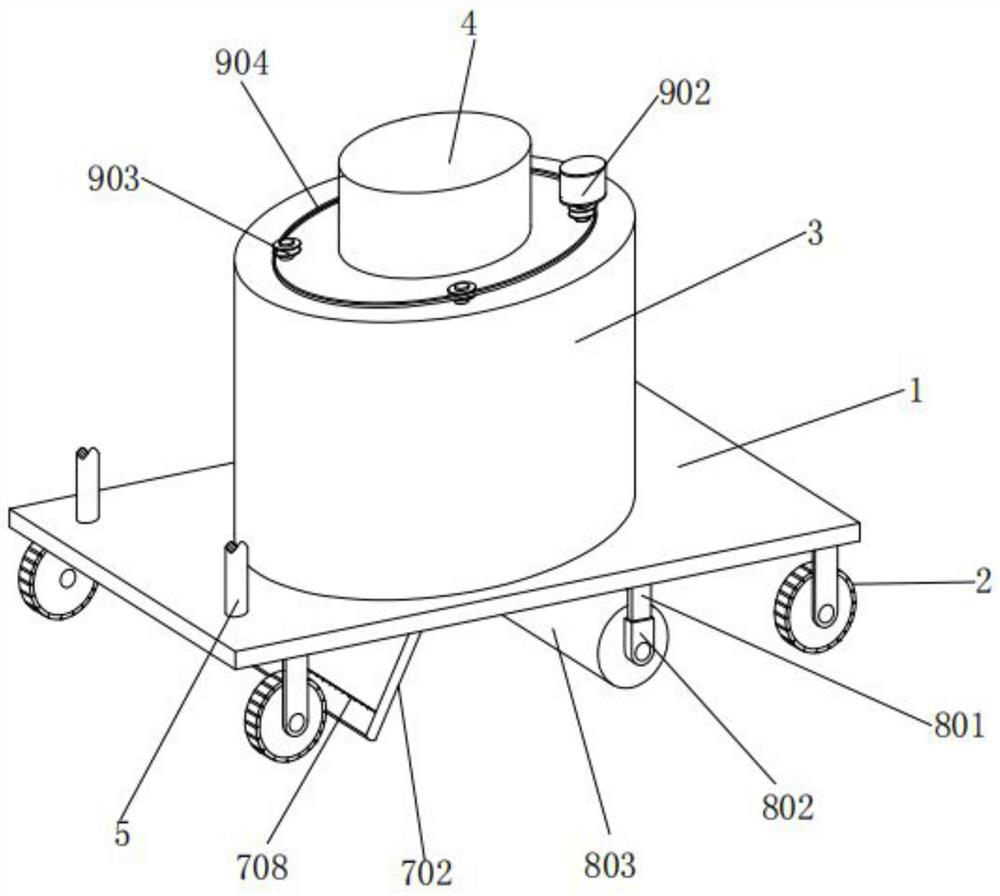

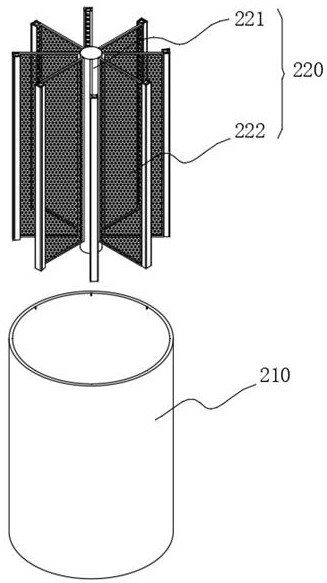

Separation device for enzyme preparation production

InactiveCN111621414AImprove separation efficiencyEasy to take outBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryStructural engineering

The invention discloses a separation device for enzyme preparation production. The separation device comprises a centrifugal box and a concentration box, a separation device body comprises the centrifugal box and the concentration box, the centrifugal box is installed on the top face of the concentration box, and supporting legs are installed on the bottom face of the concentration box; a fixing plate is arranged at the bottom of the centrifugal box, a centrifugal cylinder is rotationally installed on the top face of the fixing plate, a first motor is installed on the bottom face of the fixingplate, the output end of the first motor is connected with the bottom face of the centrifugal cylinder, multiple sets of filtering holes are evenly formed in the side wall of the centrifugal cylinder, and a limiting ring is arranged on the outer wall of the top face of the centrifugal cylinder; the limiting ring is installed on the inner wall of the centrifugal box through a supporting rod, a fixing ring is arranged on the top face of the centrifugal cylinder, and a filtering piece is connected to the fixing ring in a buckled mode; the method has the advantages that the enzyme preparation separation efficiency is improved, the stirring efficiency is high, and the enzyme preparation yield is improved.

Owner:安徽环球基因科技有限公司

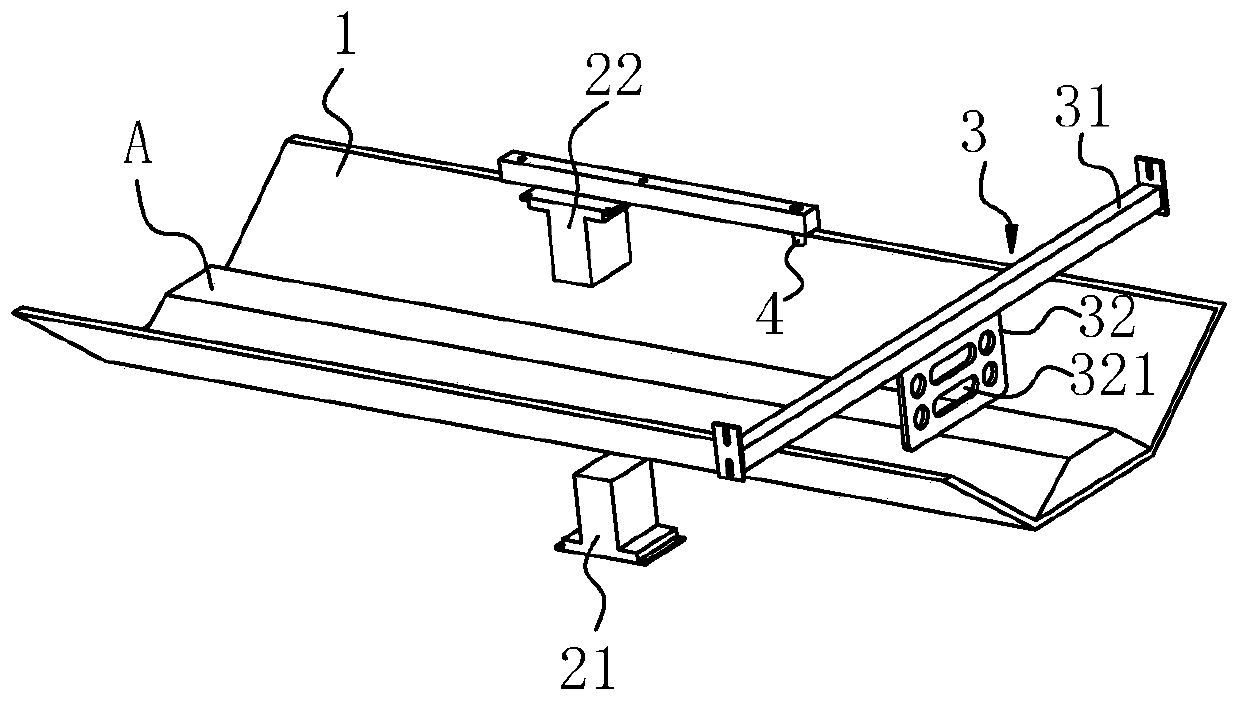

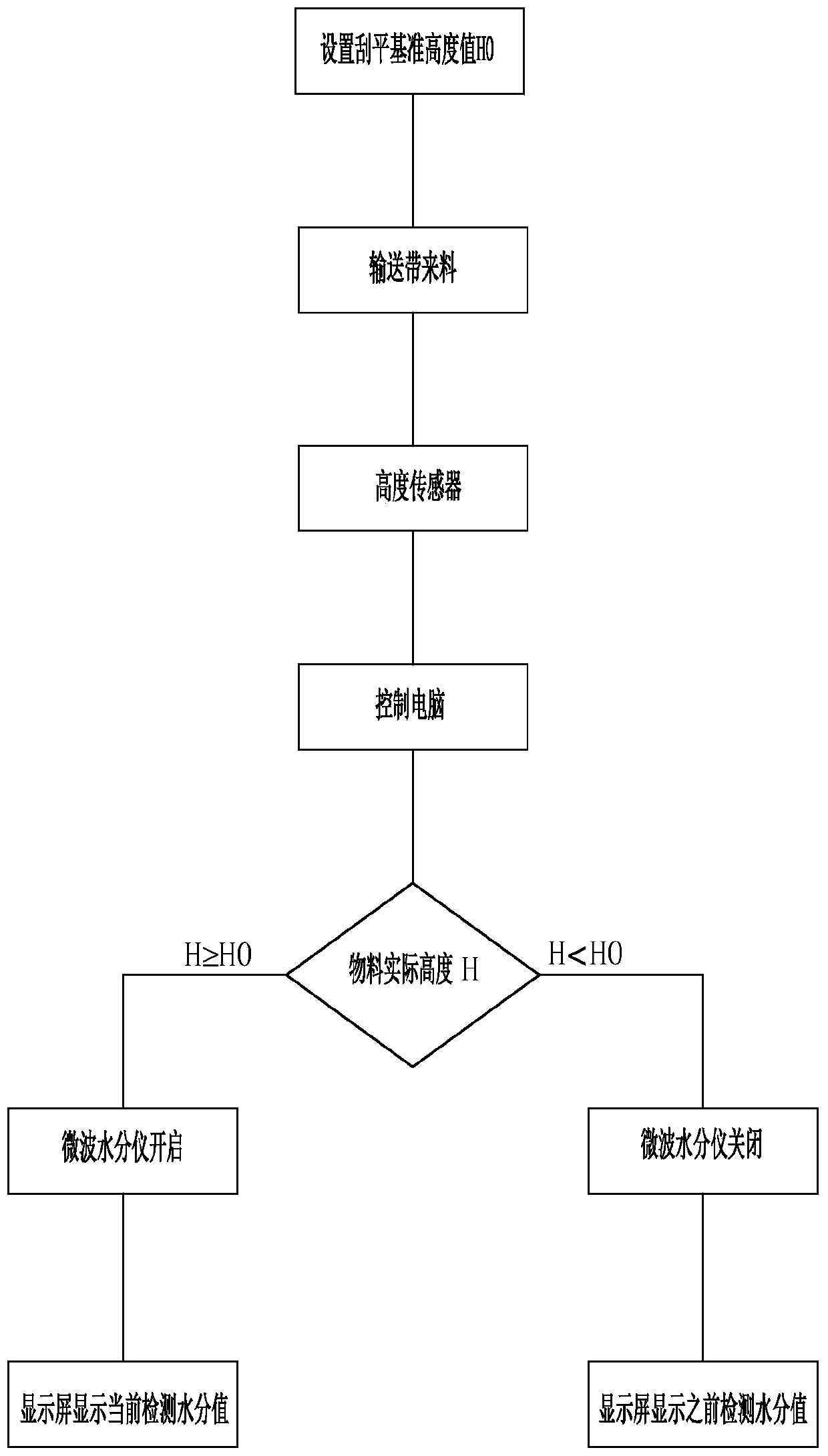

Material online moisture measuring device and measuring method thereof

PendingCN110542696AThe measured value has a small jumpImprove measurement accuracyMoisture content investigation using microwavesMaterial dimension controlPhysicsMicrowave

The invention discloses a material online moisture measuring device and a measuring method thereof. The measuring device comprises a microwave moisture meter, a material scraping part positioned on the upstream of a microwave receiver, and a material height detecting element positioned between the microwave receiver and the material scraping part; and the microwave moisture meter and the materialheight detecting element are in communication connection with a control computer separately. According to the measuring method, the material scraping part is used for leveling the top end of the material, so that the material thickness difference is reduced, a foundation is laid for the subsequent accurate measurement of the moisture, and conditions are created; the actual height of the material is continuously detected through the material height detecting element; under the condition that the thickness of the whole sintering material on a conveying belt meets the requirements and the thickness is relatively uniform, the microwave moisture meter is started for material moisture measurement, and the measurement under the condition that the material height is relatively low is eliminated; and the moisture value difference measured by the microwave moisture meter is relatively small, the microwave moisture meter is small in measurement value jitter, and the measurement accuracy is greatly improved.

Owner:WEIFANG LICHUANG ELECTRONICS TECH

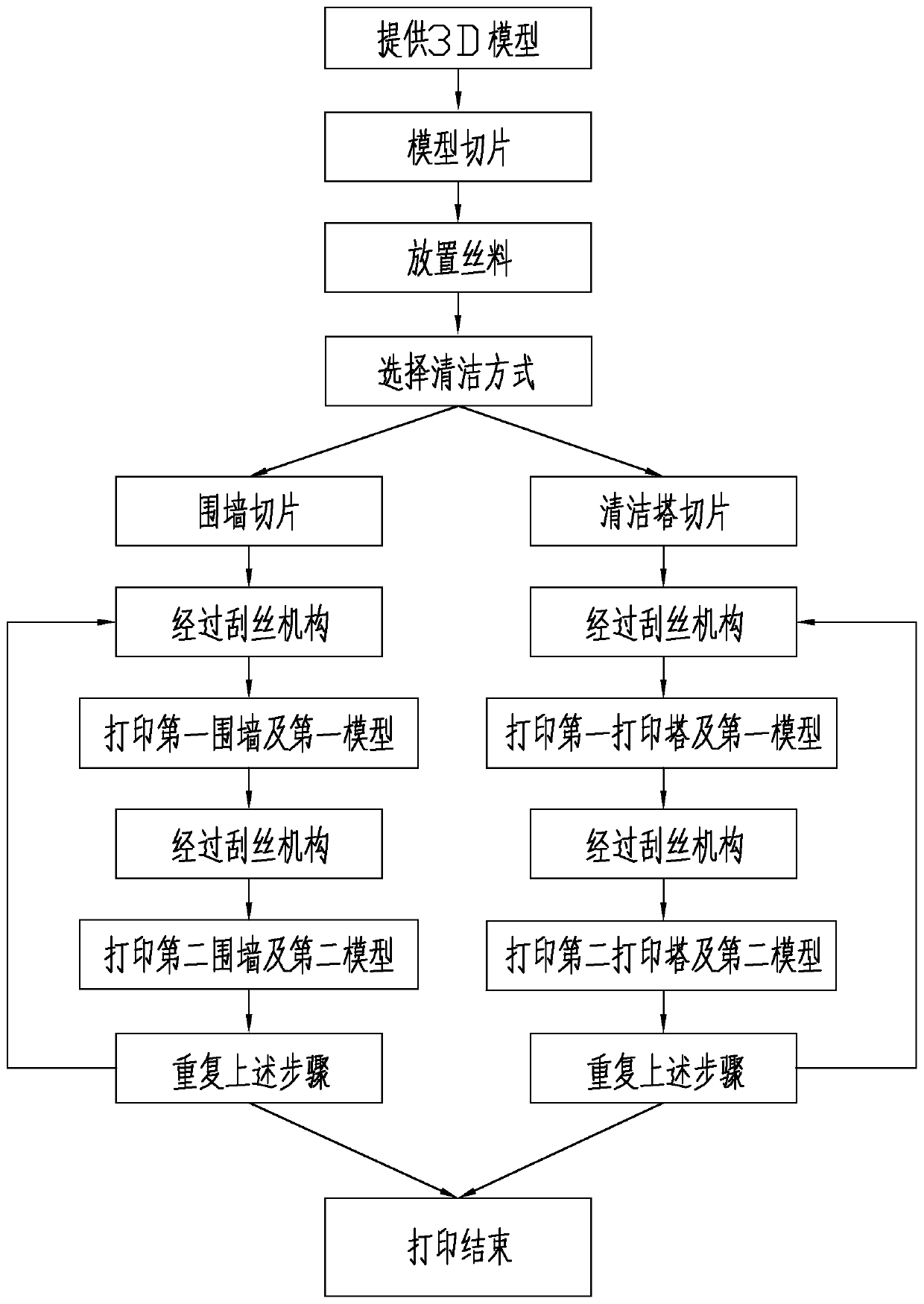

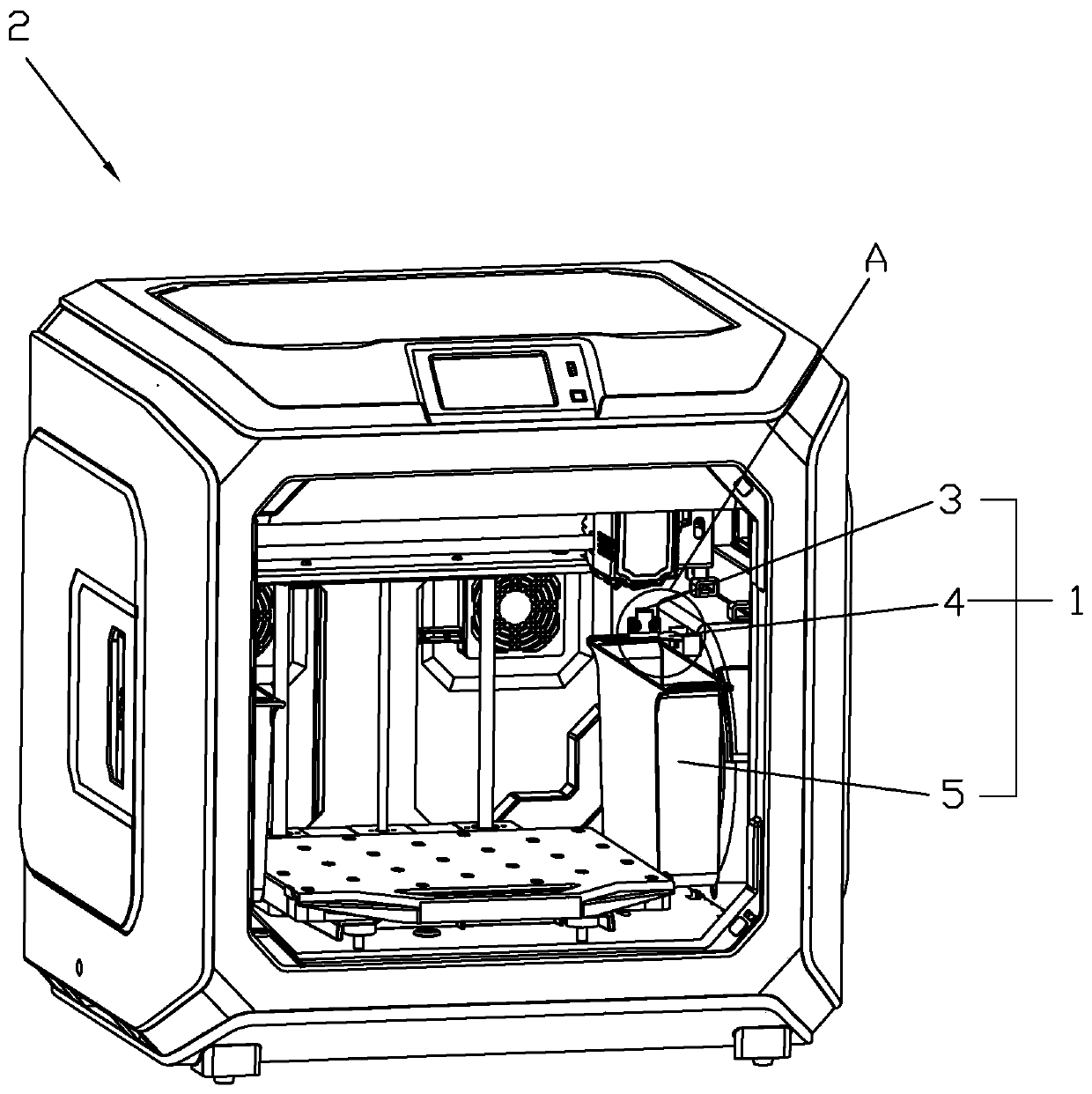

Multi-spray head 3D printing method

InactiveCN110576601ASmooth silkImprove printing qualityAdditive manufacturing apparatus3D object support structuresSoftware3D printing

The invention discloses a multi-spray head 3D printing method which comprises the following steps: (1) drawing a 3D model; (2) slicing the model: importing a 3D model document into slicing software, wherein the slicing software slices the 3D model document in layers according to printing parameters, inputs the printing parameters of a cleaning mechanism, and generates layered slices of the cleaning structure according to the 3D model document; and (3) printing in turn: printing the cleaning structure and the 3D model by using a first spray head and a second spray head in turn. The multi-sprayhead 3D printing method is suitable for a multi-spray head printer which employs two silk materials of different types or silk materials of same type but different colors. As the cleaning mechanism isprinted by the printing spray heads before the 3D model is printed, residual silk materials on the printing spray heads are blocked by the cleaning mechanism, so that the printing spray heads are cleaned. In the process of printing the cleaning mechanism, the printing spray heads are heated continuously to feed silk, so that the printing spray heads feed the silk smoothly as the 3D model is printed after the printing spray heads feed the silk stably, and therefore, the printing quality is improved.

Owner:ZHEJIANG FLASHFORGE 3D TECH CO LTD

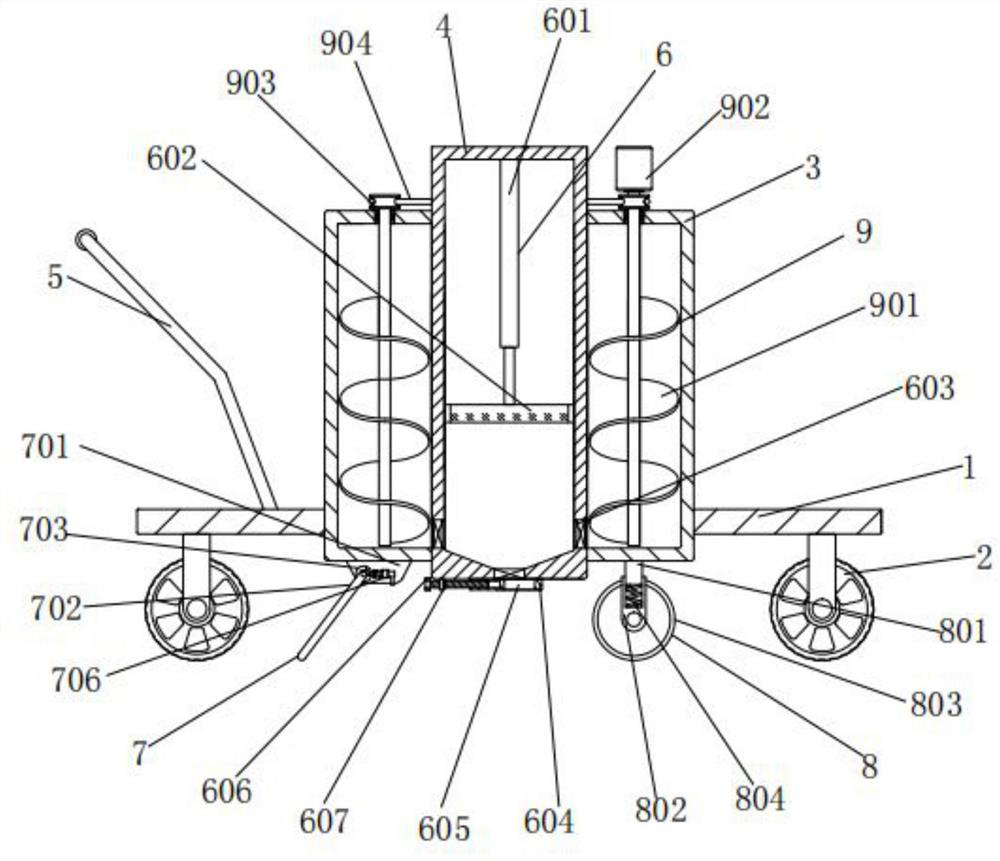

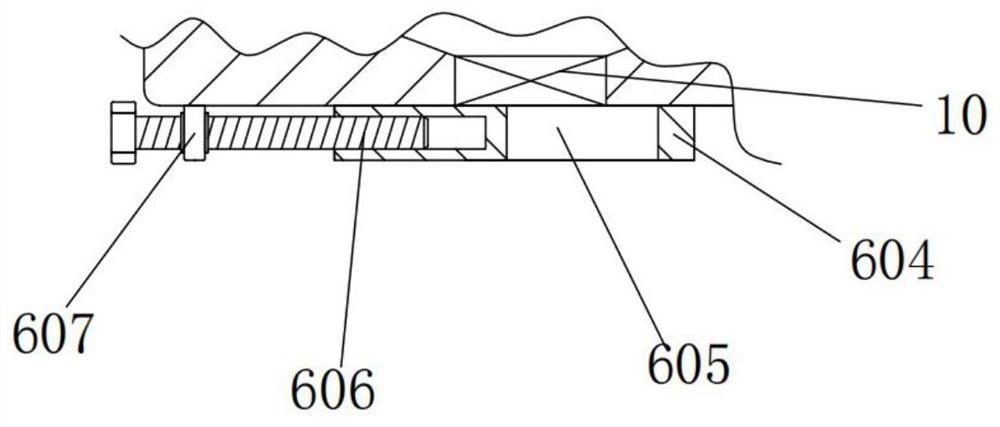

A mobile cleaning and repairing device for municipal roads

InactiveCN110904805BReduce frequency of patchingLittle impact on trafficRoads maintainenceEnvironmental resource managementCart

The invention relates to a mobile cleaning and repairing device for municipal roads, which includes a cart, a crushing mechanism, a cleaning mechanism and a watering mechanism. The crushing mechanism is installed at the right end of the lower end surface of the cart, and a Cleaning mechanism, the watering mechanism is installed at the left end of the lower end surface of the trolley, the cleaning mechanism is located at the right left end of the crushing mechanism, and the watering mechanism is located at the right left end of the cleaning mechanism. A mobile cleaning and repairing device for municipal roads according to the invention. The municipal roads are cleaned and repaired with a step-by-step continuous design concept, so that one device can complete multiple tasks, improve work efficiency, reduce the probability of pits forming again near the edge of the repair pit, and reduce road repairs frequency, thereby reducing the impact on traffic on this road section due to road repairs.

Owner:CHINA FIRST HIGHWAY ENG +1

Sealing device for material bucket capable of stirring concrete

InactiveCN110733119AStir thoroughlyPlay the role of scrapingEngine sealsMechanical machines/dredgersHydraulic motorImpeller

The invention relates to a sealing device for a material bucket capable of stirring concrete. The sealing device comprises a bucket body, wherein a stirring shaft driven by a hydraulic motor is rotatably mounted in the bucket body, an intermediate impeller is fixedly installed in the middle of the stirring shaft, a left spiral blade and a right spiral blade which are opposite to each other in rotation direction are arranged on the two sides of the intermediate impeller correspondingly, bearing boxes are mounted on the two side walls of the bucket body correspondingly, bearing chambers are arranged in the bearing boxes correspondingly, bearings are installed in the bearing chambers, the stirring shaft is mounted on the bearings, and the hydraulic motor is located on the outer side of the bucket body and is mounted on the bearing boxes. The device has the following effects that 1), a double oil seal structure of a framework oil seal and a mechanical seal assembly is adopted, the sealingcapability of the product in a harsh environment is improved, and the service life of the product is prolonged; 3), an impeller cover is in a frustum shape, materials can be prevented from being bonded to a mechanical seal box, cleaning is convenient, secondary sealing can be carried out on the mechanical seal box, and the sealing effect is improved.

Owner:莱州市三能工贸有限公司

Width measuring and repairing device for preventing and treating mass concrete cracks and operation method

PendingCN113775198AHigh repair accuracyAvoid wastingBuilding repairsMechanical engineeringMass concrete

The invention discloses a width measuring and repairing device for preventing and treating mass concrete cracks and an operation method. The width measuring and repairing device comprises a vehicle body, wherein a sleeve is fixedly connected to the inner part of the vehicle body in a penetrating manner; a vertical cylinder is fixedly connected to the inner part of the sleeve in a penetrating manner; and a repairing mechanism is arranged in the vertical cylinder. According to the width measuring and repairing device for preventing and treating mass concrete cracks disclosed by the invention, the control of a grouting range and a grouting amount is realized through the size of the staggered area of a through hole and an opening in the bottom of the vertical cylinder, so that the repairing accuracy is improved, and the width measuring and repairing device is suitable for cracks of different sizes; besides, waste can be avoided; during expansion, after grouting is performed at the cracks, the width measuring and repairing device can have the effect of scraping flatly, so that the repairing flatness is improved; scale lines are arranged, so that the width of the cracks can be measured through comparing a scraping plate with the width of the cracks; after grouting is performed at the cracks, rolling can be performed, so that the repairing compactness is improved, and the repairing quality is improved; and the width measuring and repairing device has the effect of stirring slurry, so that the slurry is prevented from solidifying, the quality of the slurry is improved, and the repairing effect is further improved.

Owner:CHINA MCC17 GRP

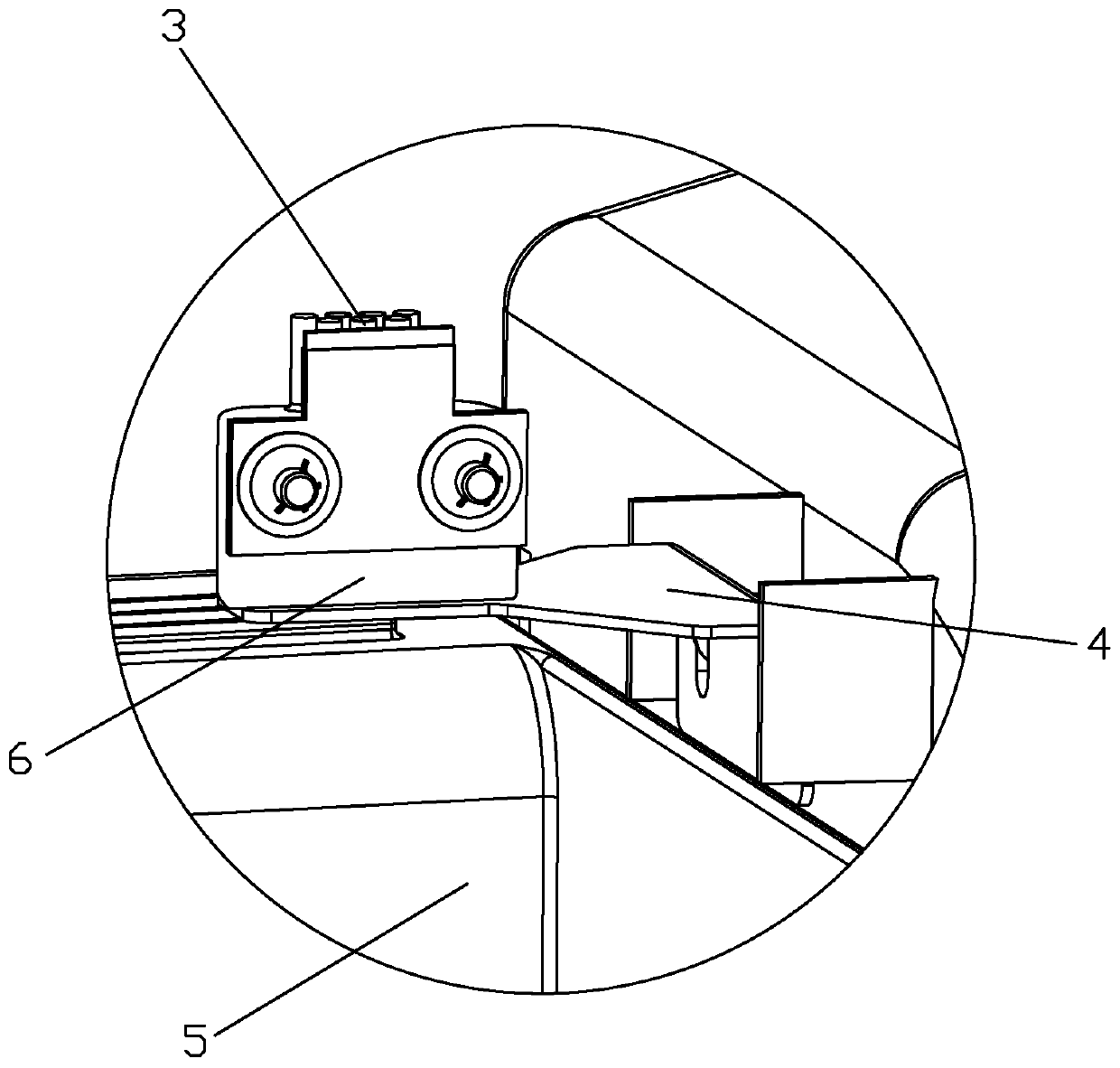

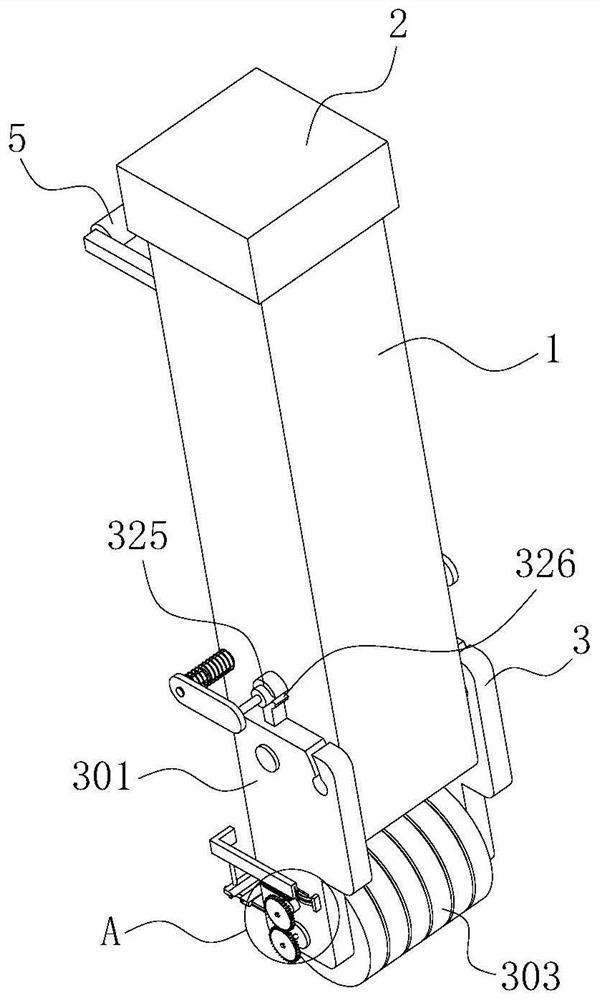

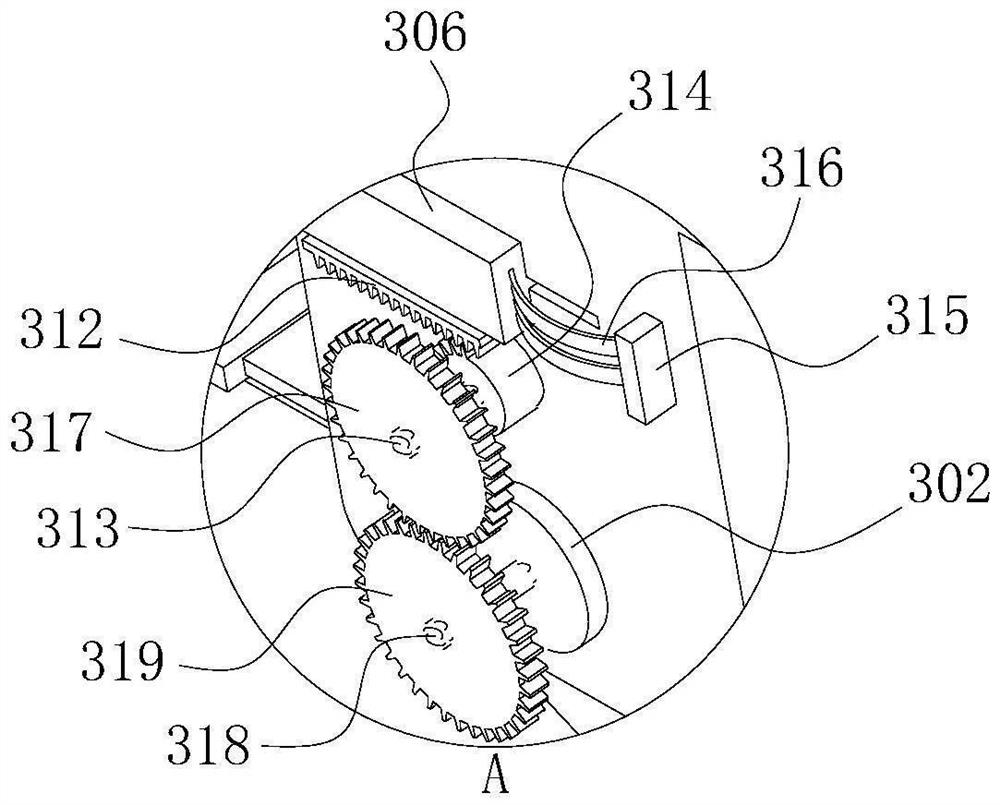

Geophysical exploration equipment suitable for complex terrains

InactiveCN114675344ASmooth runningPlay the role of scrapingPortable framesGeological measurementsTerrainClassical mechanics

The invention belongs to the technical field of exploration, and particularly relates to geophysical exploration equipment suitable for complex terrains, which comprises a mounting column, an exploration instrument mounted at the top of the mounting column, a walking mechanism mounted at the bottom end of the mounting column, a square groove formed in the bottom surface of the mounting column in the length direction of the mounting column, and a supporting mechanism mounted on the mounting column. A push-pull handle is fixedly mounted on the outer wall of the mounting column; when the exploration equipment provided by the invention is transferred on the grassland, soil cannot adhere to the surfaces of the walking wheels, and grass cannot wind the walking wheels; in the exploration equipment provided by the invention, the angles of the four supporting arms can be independently adjusted, and the angles of the supporting arms can be limited to ensure that the supporting arms can be always attached to the earth surface, so that the exploration equipment is ensured to be in a stable static state during working.

Owner:山东省地质矿产勘查开发局第五地质大队

A multi-stage filter grease trap

ActiveCN113559608BEasy to handle collectionEasy to handleFatty/oily/floating substances removal devicesGeneral water supply conservationOil canFiltration

The invention relates to the technical field of oil separators, in particular to a multi-stage filtration oil separator, comprising a pool body, a separation mechanism is arranged in the pool body, a screening mechanism is arranged in the pool body, and the screening mechanism There is a scraping mechanism on it, a flushing mechanism is arranged in the tank body, a cleaning mechanism is arranged on the separating mechanism, an adjusting mechanism is arranged on the separating mechanism, and an oil scraping mechanism is arranged on the tank body; The cooperation between the mechanism and the sweeping mechanism can better handle the solid waste in the sewage, avoid the blockage of the basket net by the solid waste, and improve the treatment effect of the sewage; The height of the tank can be adjusted, which is convenient for the treatment of different types of swill; the oil scraping mechanism is located inside the tank body, which is convenient to push and scrape the oil floating on the surface, so that the oil can be discharged more smoothly, and it is also convenient for Scrape off the oil stains on the inner wall of the equipment to reduce the generation of odors.

Owner:深圳市合众源环保科技有限公司

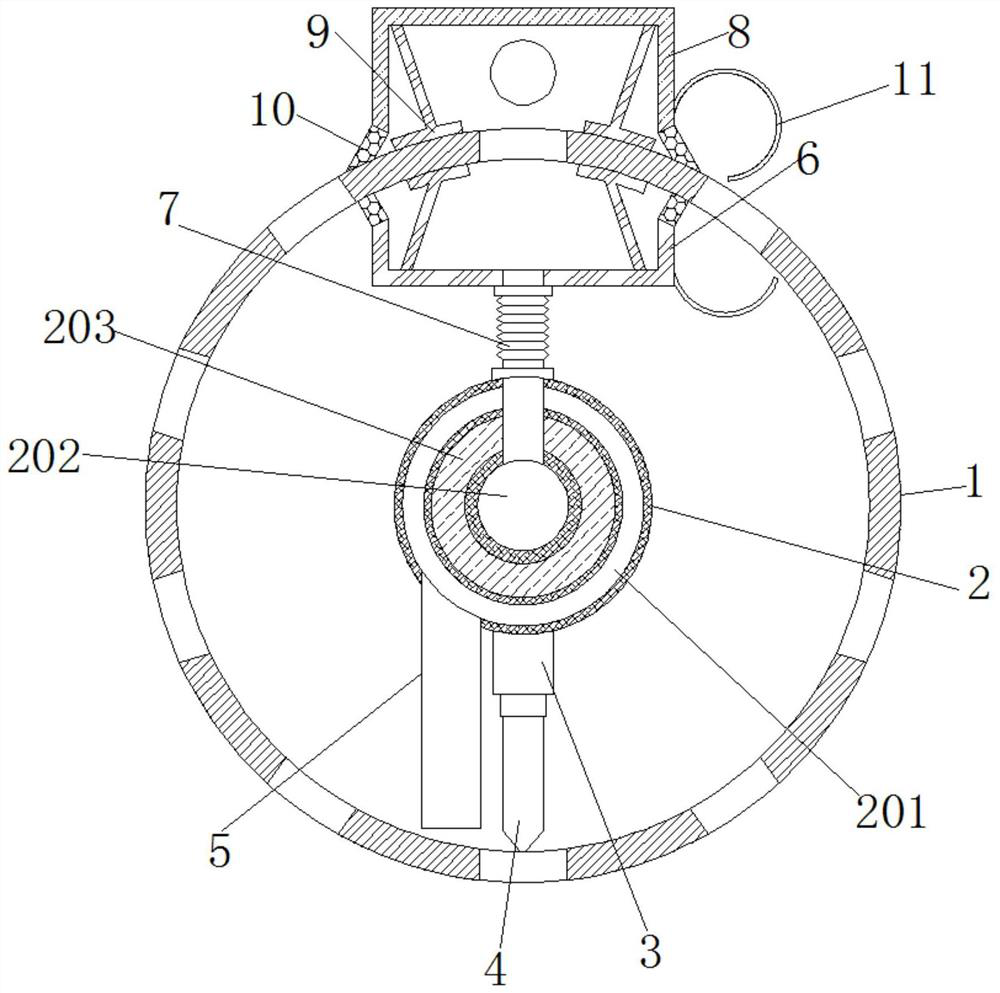

Enameled wire painting box

The invention provides an enameled wire painting box which is convenient to use. The enameled wire painting box comprises a box body, wherein the box body is provided with a box cover, and the rear side of the box cover is rotationally installed at the top of the box body through a hinge; U-shaped through holes are formed in the top of the two sides of the box body, guide wheels are arranged in the box body close to the U-shaped through holes, and the two ends of the guide wheels are rotationally installed on the front side surface and the rear side surface of the box body respectively; a roller is arranged between the two guide wheels and is rotationally mounted at the bottom end of a connecting shaft, and the top end of the connecting shaft is fixedly mounted on the box cover; a circular scraper is further arranged at one U-shaped through hole; and the guide wheels are arranged above the liquid level in the box body, the bottom surface of the roller is arranged below the liquid level in the box body, and a copper wire can penetrate through the other U-shaped through hole, sequentially winds around the upper portion of one guide wheel, the lower portion of the roller and the upper portion of the other guide wheel and then penetrates out of the circular scraper.

Owner:江苏锡洲新材料科技有限公司

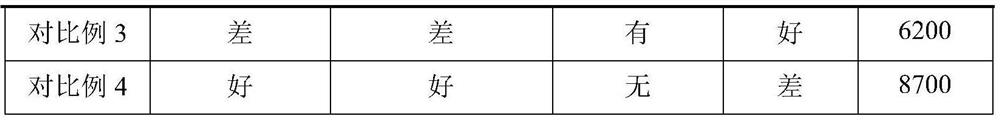

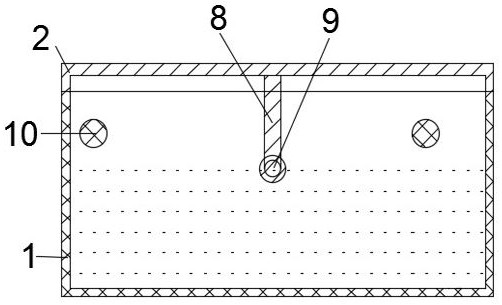

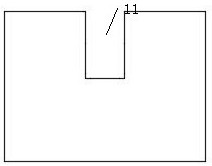

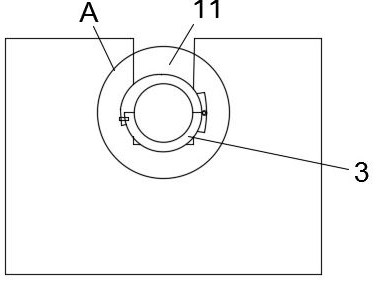

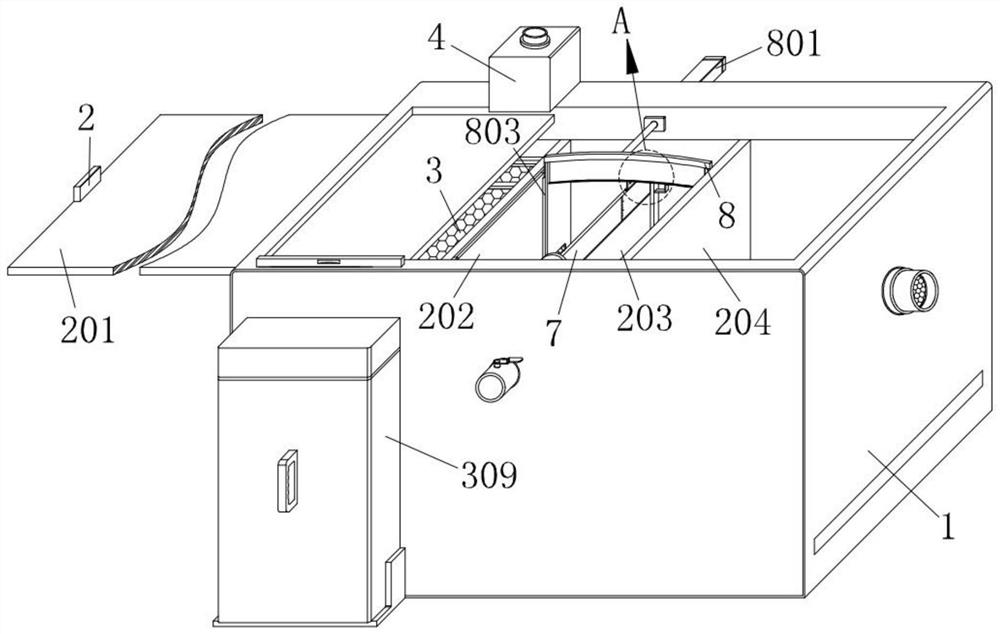

Multi-stage filtering oil separation tank

ActiveCN113559608AAvoid cloggingImprove work efficiency and processing effectFatty/oily/floating substances removal devicesGeneral water supply conservationOil separationSewage treatment

The invention relates to the technical field of oil separation tanks, in particular to a multi-stage filtering oil separation tank which comprises a tank body, a separation mechanism arranged in the tank body, a screening mechanism arranged in the tank body, a scraping and sweeping mechanism arranged on the screening mechanism, a washing mechanism is arranged in the tank body, a sweeping mechanism is arranged on the separation mechanism, an adjusting mechanism is arranged on the separation mechanism, and an oil scraping mechanism is arranged on the tank body. Through cooperation of the screening mechanism and the scraping and sweeping mechanism, solid waste in sewage can be better treated, the phenomenon that a basket net is blocked by the solid waste is avoided, and the sewage treatment effect is improved; the adjusting mechanism is arranged in the separation mechanism, so that the height of an oil separation plate 203 can be conveniently adjusted, and the height is conveniently suitable for treatment conditions of different types of swill; the oil scraping mechanism is arranged in the tank body, so that the oil dirt floating on the surface can be pushed and scraped conveniently, the oil dirt can be discharged more smoothly, meanwhile, the oil dirt attached to the inner wall of equipment can be scraped conveniently, and peculiar smell is reduced.

Owner:深圳市合众源环保科技有限公司

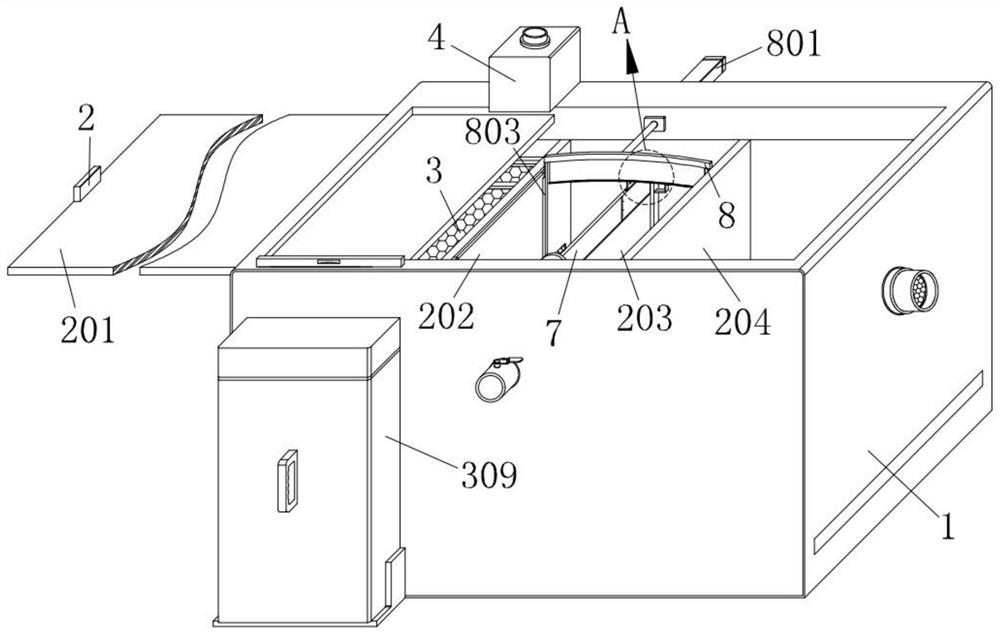

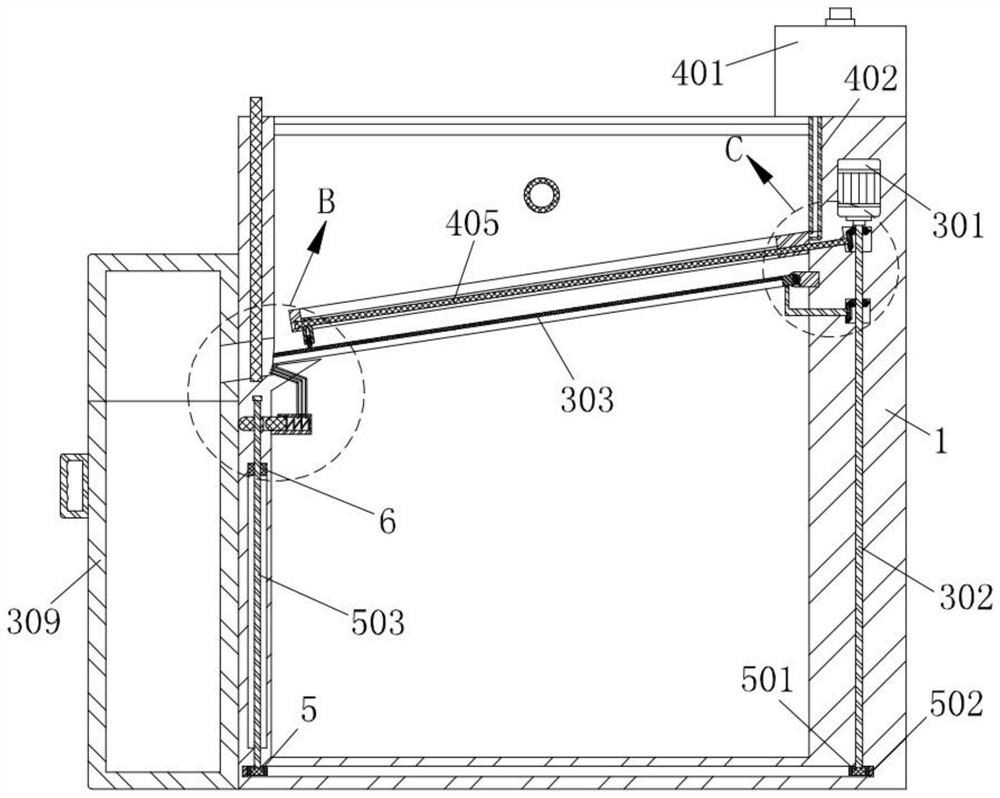

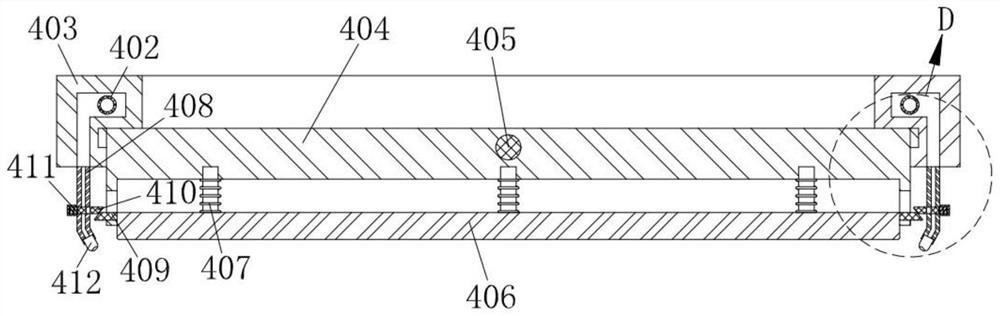

A hull derusting and painting equipment

ActiveCN111644285BStir wellPlay the role of scrapingGrinding drivesSpraying apparatusLacquerEngineering

The invention provides a hull derusting and painting equipment, comprising a base, a No. 1 moving assembly, a No. 2 moving assembly, a central shaft, an H-shaped bracket, a painting assembly, and a grinding disc assembly. The battery is fixedly connected between the right side of the baffle, the H-shaped bracket is connected between the left side of the baffle, and the left side of the H-shaped bracket is fixedly connected with the painting assembly. Push rod, the telescopic end at the top of the No. 1 electric push rod is fixedly connected with the bottom of the central connecting rod of the H-shaped bracket, and the No. 1 electric push rod is electrically connected with the battery. Both sides are sleeved with sliders, and the upper end of the slider is located between the slider and the partition and is sleeved with a spring. The invention provides a hull rust removal and painting equipment to solve the pollution of the environment due to the labor intensity of manual rust removal and painting of the hull and the existing paint spraying equipment. The equipment is easy to block and cause low work efficiency.

Owner:刘伦宇

An agricultural product processing and peeling machine

ActiveCN110916208BEasy to handlePlay the role of scrapingVegetable peelingAgricultural engineeringElectric machinery

The invention discloses a peeling machine for processing agricultural products, which comprises a main body of the peeling machine, a fan, a hose, a connecting pipe, a motor, a feeding platform and a conveyor belt. The pipe is connected with the connecting pipe, and the opening on the right side of the main body of the peeling machine is welded with a feed table, and the opening on the left side of the main body of the peeling machine is welded with a discharge table, and the top of the right side inside the main body of the peeling machine A support frame is provided, and a conveyor belt is provided below the support frame, and the conveyor belt is connected to the motor through a drive roller at one end thereof, and the inner end of the upper screw rod of the second peeling sheath is connected to the peeling head through a second connecting block. connected, and the inner ends of the screw rods on both sides of the lower part of the second peeling sheath are connected with the peeling head through the first connecting block. The agricultural product processing and peeling machine can quickly scrape off the skin of strip-shaped raw materials such as yam, and facilitate the subsequent processing of strip-shaped raw materials such as yam.

Owner:子长市窑洞娃食品有限公司

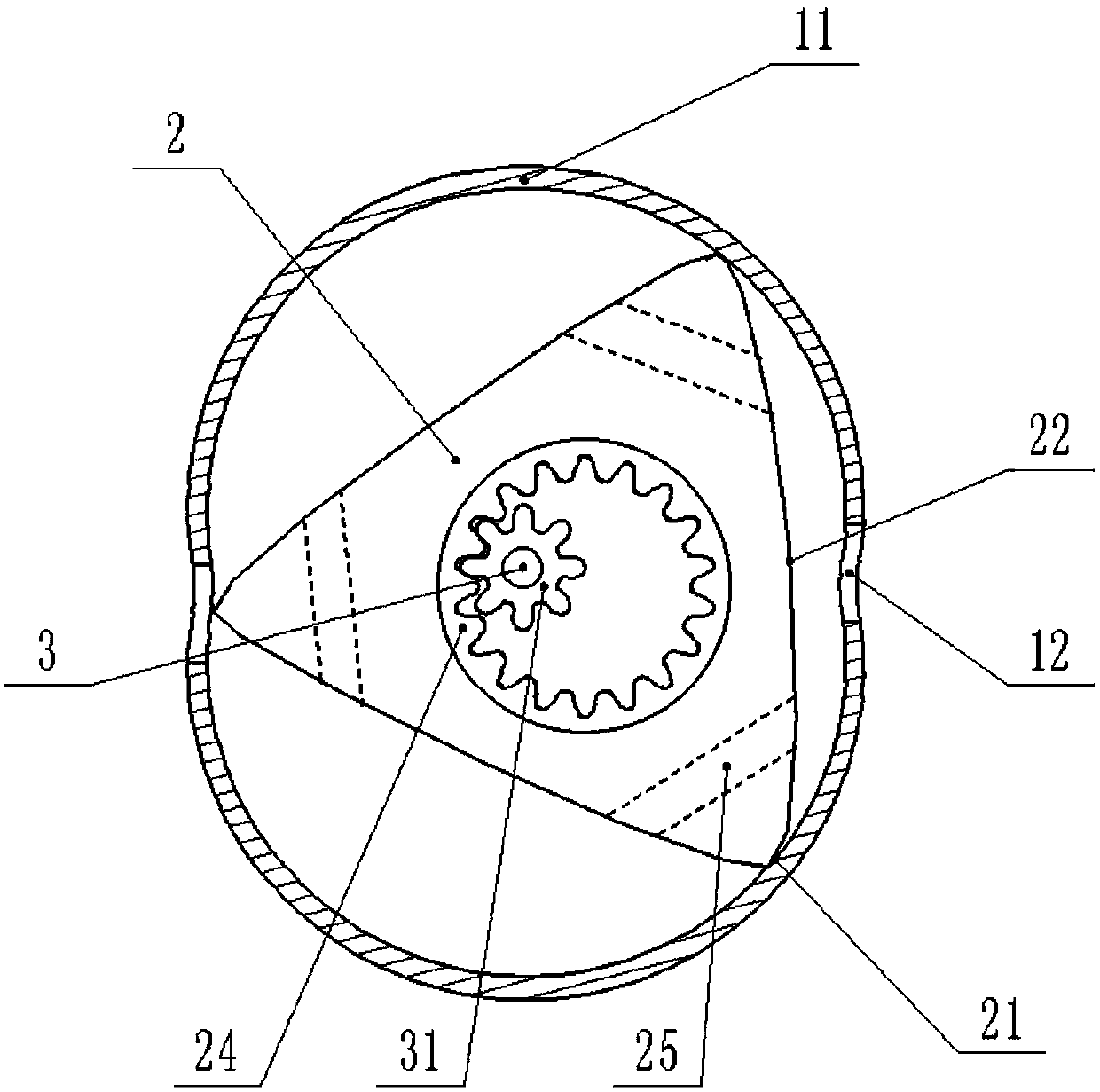

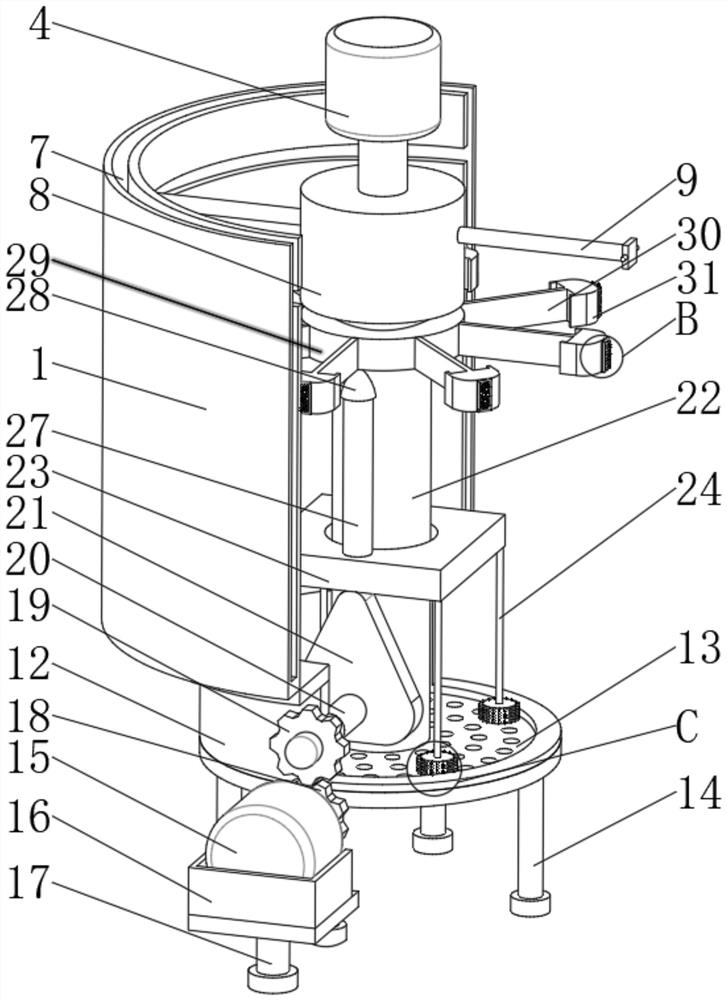

A cold precipitation crystallizer for chemical production

ActiveCN110772830BPlay the role of scrapingNo wall stickingSolution crystallizationHeat exchange cooling cystallizationGear wheelElectric machinery

The invention relates to the technical field of chemical production equipment, and discloses a cold precipitation crystallizer for chemical production, including a shell, the inside of the shell is provided with a mounting column, and the left and right ends of the mounting column are fixedly connected with an air outlet pipe A cooling chamber is opened on the inner wall of the housing, and the air outlet pipe runs through the inner wall of the housing and is located inside the cooling chamber. The cold precipitation crystallizer used in chemical production drives the main gear to rotate through the auxiliary electrode, and the secondary transmission gear rotates. When crystals adhere to the inside of the shell, the auxiliary motor is turned on to drive the cam at the other end of the installation shaft to rotate. Rotate the movable plate at the top of the cam and move up and down to drive the lifting movement of the lifting rod and the lifting block at the top, and the installation ring at the top of the lifting block drives the stirring rod to do reciprocating lifting movement immediately. The brush then scrapes the inner wall of the housing to achieve the advantage of not sticking to the wall.

Owner:衡阳凯美科化工有限公司

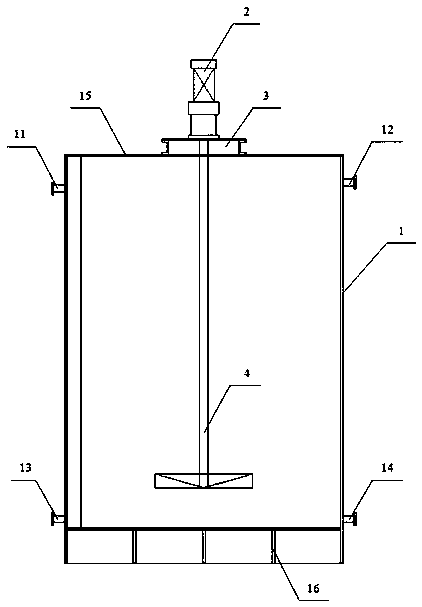

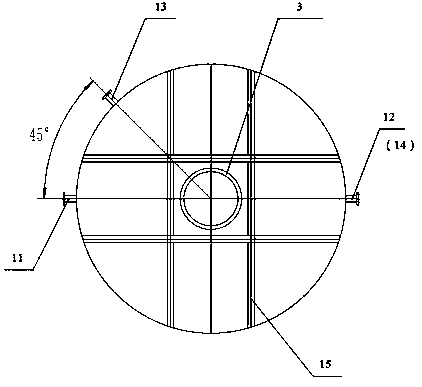

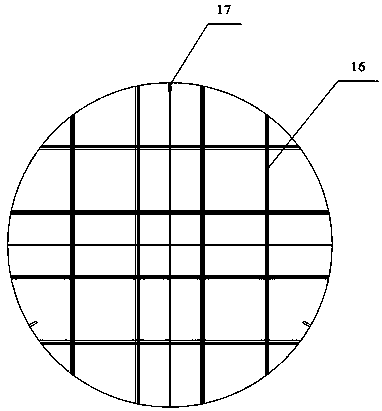

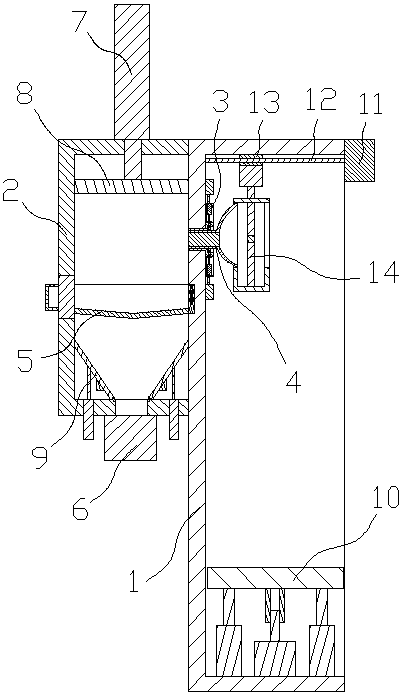

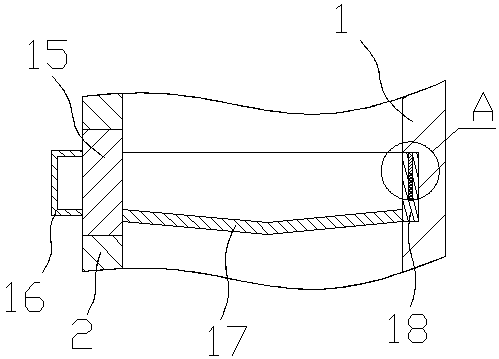

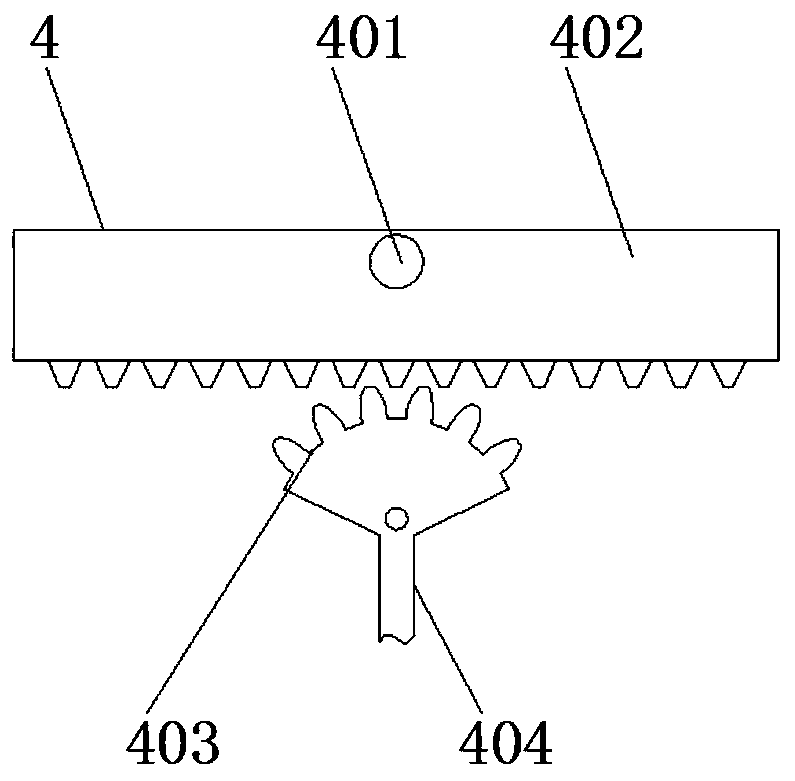

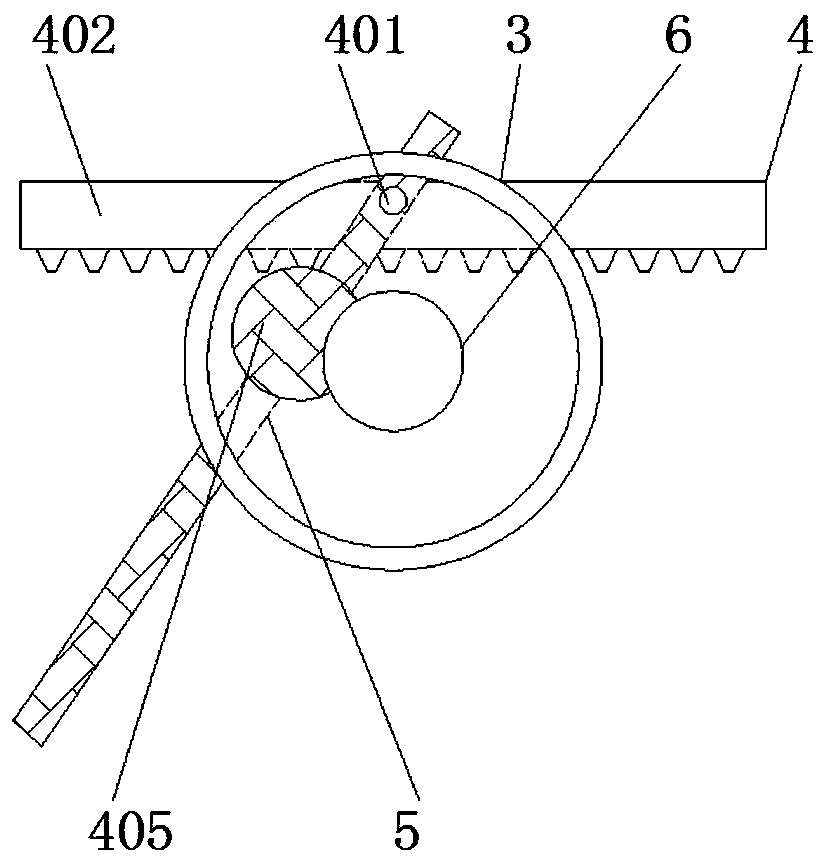

A reactor for solid waste treatment

ActiveCN108620010BAvoid accumulationGuaranteed uptimeRotary stirring mixersTransportation and packagingSewage outfallEngineering

The invention relates to a reactor for solid waste treatment, comprising a reactor body (1), a liquid inlet (11) and an overflow port (12) are arranged above the outer periphery of the reactor body (1); the reactor body ( 1) is provided with a liquid outlet (13) and a sewage outlet (14) below the outer periphery; the drive device (2) is connected to the top of the reactor body (1) through the bearing (3), and the drive device drives the inside of the reactor body (1) The stirring paddles (4) rotate synchronously; avoid the accumulation of stirring materials between the drive shaft and the connection part of the cutter head, reduce the waste of raw materials, ensure the long-term operation of the stirring paddles, prolong the service life of the stirring paddles, and reduce the maintenance frequency and maintenance of the stirring paddles overhead.

Owner:镇江新区固废处置股份有限公司

Dust mask effect demonstration machine capable of realizing concentration regulation of different dust particles

InactiveCN108492703AGood and convenient concentration adjustment effectSimple structureEducational modelsEngineeringDust particles

The invention relates to a dust mask effect demonstration machine capable of realizing concentration regulation of different dust particles. The dust mask effect demonstration machine comprises a demonstration cabinet and a dust particle cabinet, wherein a communicating hole matched with the dust particle cabinet is formed in the left side wall of the demonstration cabinet, a dust mask is in fit in the communicating hole and is clamped by a mask clamping mechanism in the demonstration cabinet, a dust particle picking and placing device is arranged at a part, located below the communicating hole, of the dust particle cabinet, a base plate of the dust particle picking and placing device is a ventilation plate, a dust blowing air port is formed in the lower side of the dust particle cabinet,the dust blowing air port is communicated with a dust blowing fan, a concentration regulating air cylinder which is a vertical trend and penetrates the interior of the dust particle cabinet is arranged at the upper part of the dust particle cabinet, and a concentration regulating block in seal fit with the dust particle cabinet is connected below the concentration regulating air cylinder. The dustmask effect demonstration machine provided by the invention has the advantages that the concentration regulating block is controlled to go up and down by virtue of the concentration regulating air cylinder, further volume of a dust particle cavity is regulated, the effect of regulating concentrations of the dust particles is achieved, the condition that quantity of the dust particles is too largeand beyond a blowing range of the fan cannot occur, and then the good and convenient dust particle concentration regulating effect is realized.

Owner:DONGGUAN UNIV OF TECH

A medical sewage treatment device based on centrifugal separation of floating objects

The invention relates to a sewage treatment device, in particular to a medical sewage treatment device for separating floating objects based on a centrifugal type. It includes an external mechanism including an outer casing, the internal mechanism is arranged in the outer casing, and an internal mechanism including an inner casing and a separate assembly. In the present invention, through the interference of the separation plate, the sewage in the inner casing cannot form a vortex, thereby reducing the impact of the vortex on the floating matter, and the reduced floating matter will be attached to the filter surface, and then subjected to the centrifugal force. The floating matter attached to the filter surface moves to the eccentric place and enters the collecting part corresponding to the moving direction, and then after reducing the vortex, the filter surface cooperates with the centrifugal force to realize the collection of floating objects, which eliminates the interference of the vortex and facilitates The treatment of floating objects in the later stage.

Owner:WEIFANG WOHUA WATER TREATMENT EQUIP

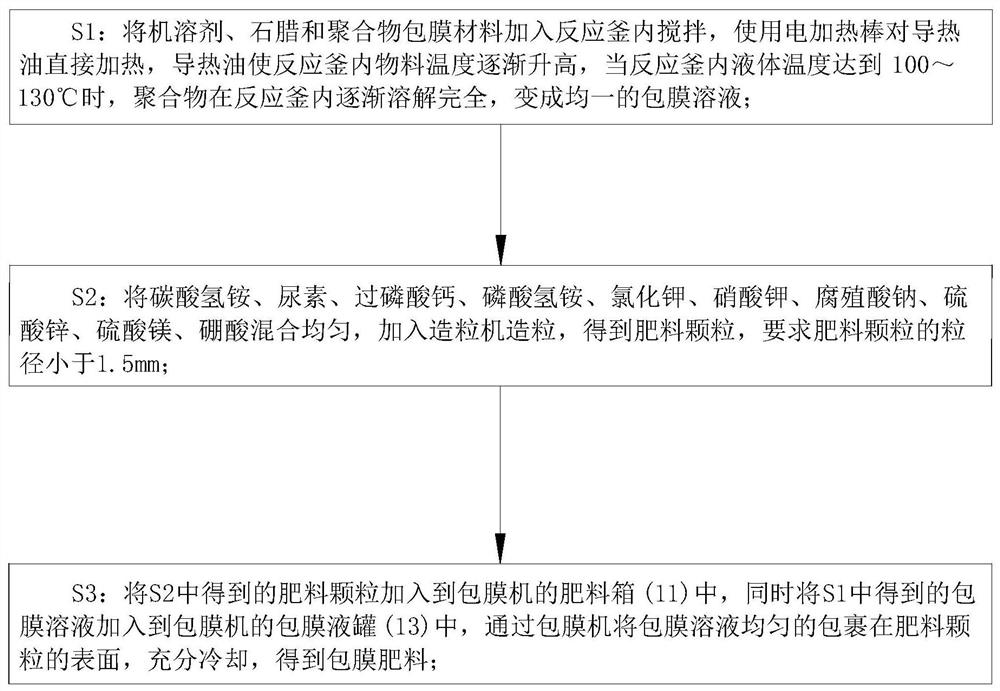

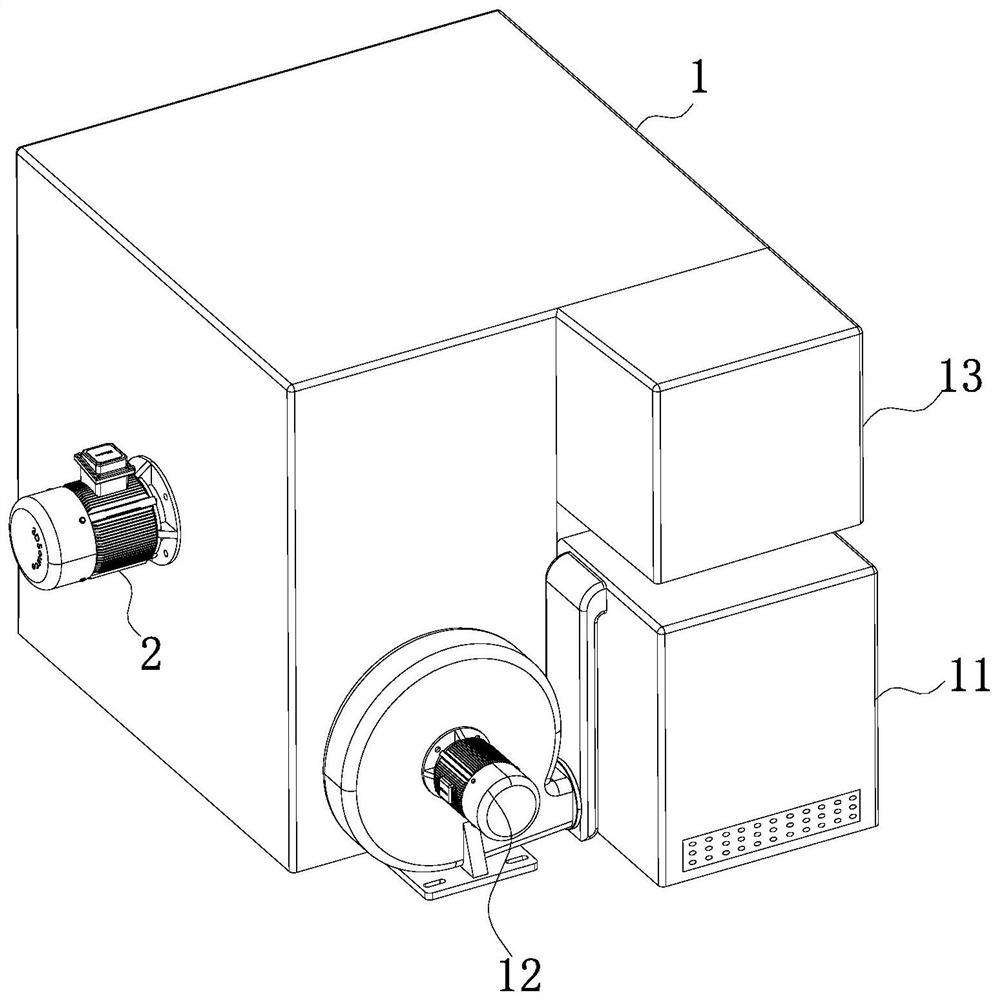

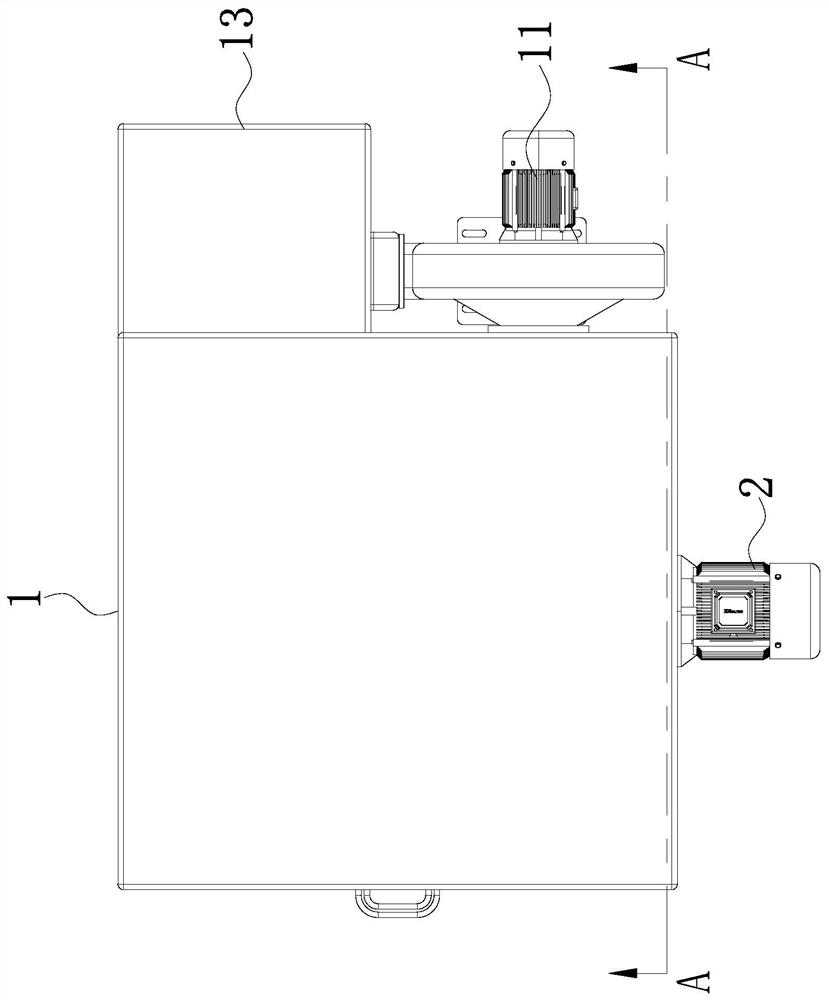

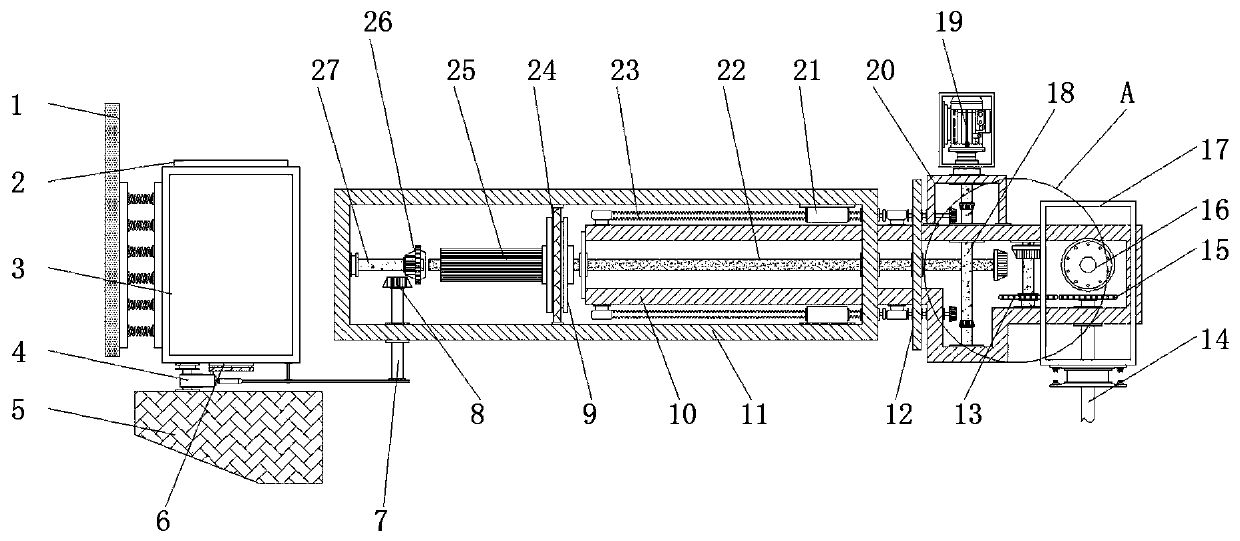

Fertilizer coating process

InactiveCN112409064AUniform coating thicknessFast coatingSuperphosphatesMagnesium fertilisersAgricultural scienceElectric machine

The invention belongs to the technical field of fertilizer coating production, and particularly relates to a fertilizer coating process, a coating machine used in the fertilizer coating process comprises a machine shell, a rotating motor and a fixed pipe; a working cavity is formed in the machine shell; a fixed pipe is fixedly connected to the interior of the working cavity; the front end face ofthe machine shell is fixedly connected with a rotating motor; a fertilizer box is fixedly connected to the position, close to the rear end face of the shell, of the right side face of the shell. According to the fertilizer coating device, rapid coating of the surfaces of fertilizer particles is effectively realized, a fertilizer layer is uniformly sprayed on the surface of the coating adhesive plate, then a coating solution is sprayed, and the problems of extrusion collision and stacking between the fertilizer particles are avoided, so that the coating thickness of the surfaces of the fertilizer particles is relatively uniform. If the coating thickness needs to be controlled, repeated coating can be carried out for multiple times, so that the coating thickness is effectively controlled, and the quality stability of the coated fertilizer is improved.

Owner:当涂县江心仁贵家庭农场

Furnace ramming mechanism of furnace ramming vehicle for large-capacity submerged arc furnace

ActiveCN109990604AReasonable structureFlame reduction featureCharge manipulationElectrical conductorDrive shaft

The invention discloses a furnace ramming mechanism of a furnace ramming vehicle for a large-capacity submerged arc furnace. The ramming mechanism comprises a protection mechanism, a scraping mechanism, an inner cylinder body and an outer cylinder body; a limiting plate is arranged outside the inner cylinder body; a shell is arranged on one side of the outside the inner cylinder body, the shell isfixedly connected with the inner cylinder body through a fixing plate, a first driving shaft is vertically fixed inside the shell, and the top end of the first driving shaft penetrates through the outer wall of the inner cylinder body and extends into the inner cylinder body. The protection mechanism is arranged on one side of a hopper, connecting seats are fixed on the opposite sides of a high-temperature-resistant ceramic protection plate and the hopper in the protection mechanism, a plurality of damping springs are fixed between the connecting seats, and the damping springs are arranged atequal intervals between the connecting seats, so that the protective effect is improved; during furnace ramming, the high-temperature-resistant ceramic protection plate plays a role in protecting, ametal conductor is prevented from causing danger by being directly collided with a large sleeve, brasses and electrodes in the furnace, and the damping springs play a certain role in buffering.

Owner:宁夏三元中泰冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com