A hull derusting and painting equipment

A technology for painting equipment and hulls, applied in metal processing equipment, grinding/polishing equipment, spray devices, etc., can solve the problems of secondary rust, nozzle blockage, operation danger, etc., to achieve uniform stirring, prevent blockage, and facilitate The effect of scraping impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

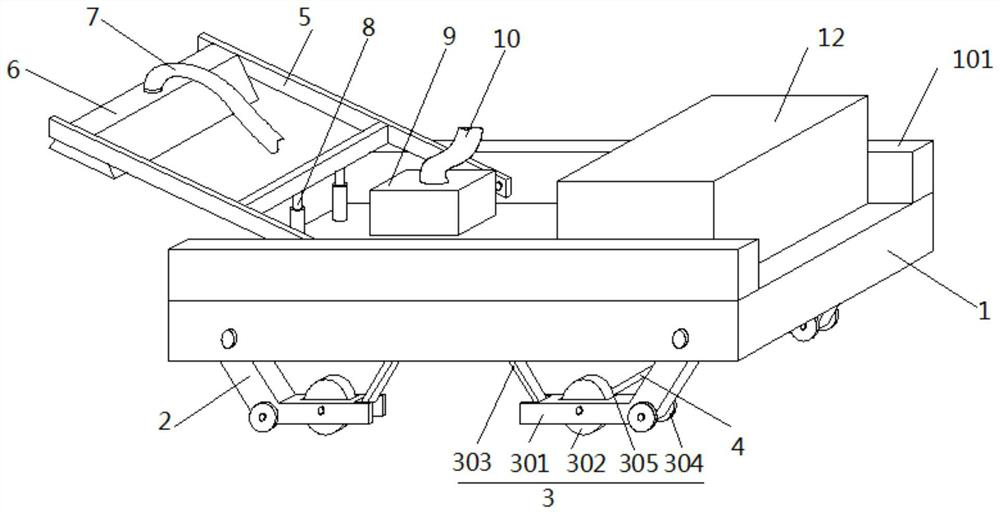

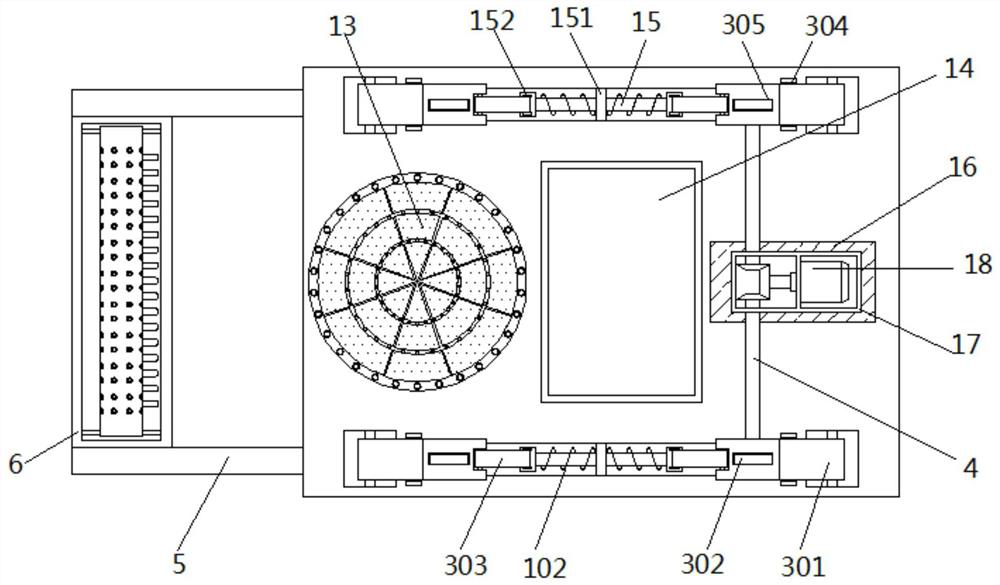

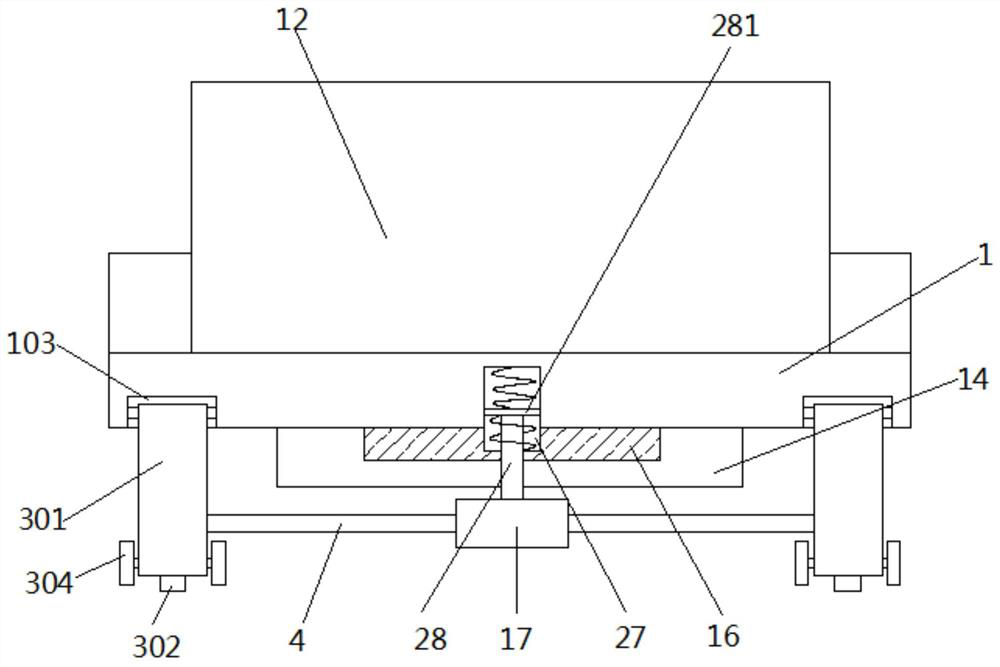

[0031] as attached figure 1 to attach Figure 10Shown: a hull derusting and painting equipment, including a base 1, a No. 1 moving component 2, a No. 2 moving component 3, a central shaft 4, an H-shaped bracket 5, a painting component 6, and a grinding disc component 13. The front and rear sides of the top of the base 1 are The baffle 101 is fixedly connected, the right side of the top of the base 1 is located between the baffles 101 and the battery 12 is fixedly connected, the H-shaped bracket 5 is connected between the left side of the baffle 101, and the left side of the H-shaped bracket 5 is fixedly connected with a painting assembly 6. The front and rear ends of the left center of the top of the base 1 are fixedly connected to a No. 1 electric push rod 8, and the telescopic end of the top of the No. 12 Electrically connected, the top of the base 1 is located between the H-shaped bracket 5 and the battery 12 and is fixedly connected with a fixed box 9, and the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com