One-time dust removal system for revolving furnace

A technology of dust removal system and converter, applied in the field of steelmaking dust removal, can solve problems such as environmental pollution, reduced dust removal efficiency, high temperature dry flue gas overflow, etc., and achieve the effects of preventing environmental pollution, improving dust removal efficiency, and preventing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

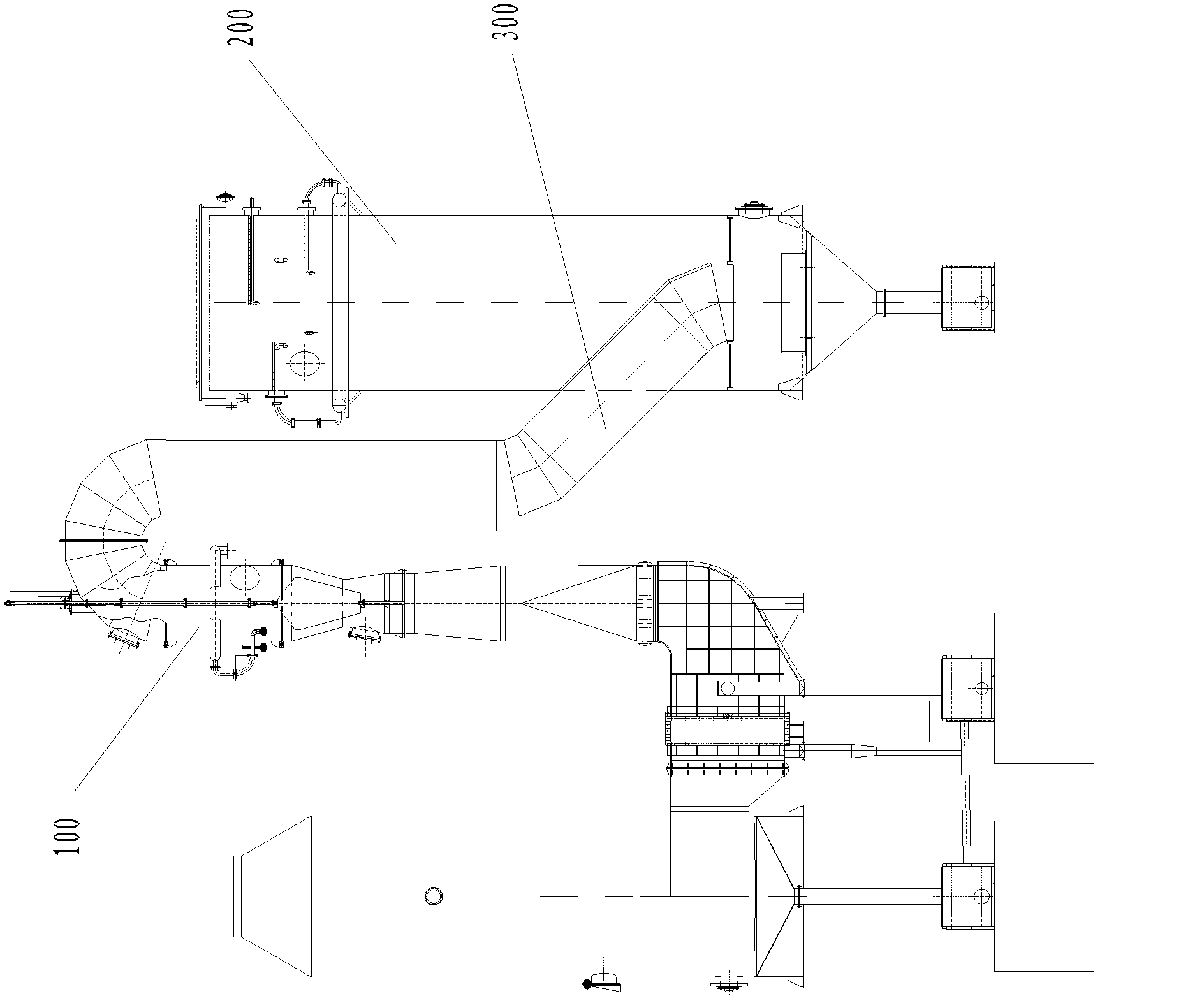

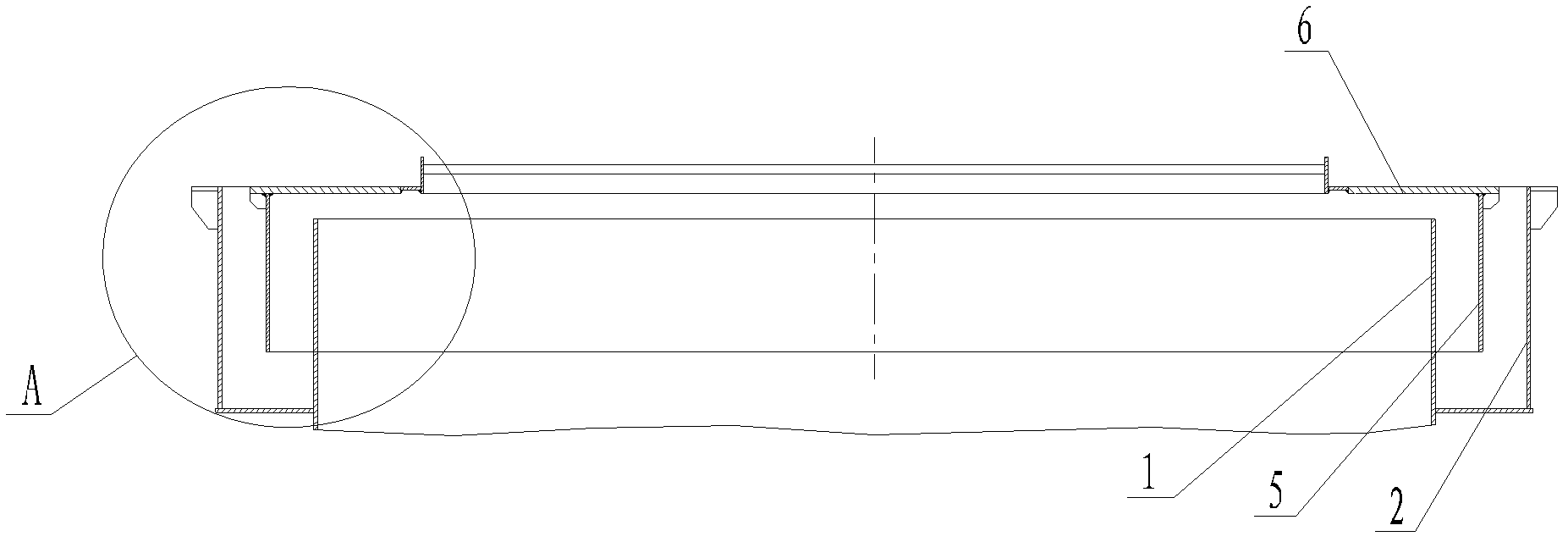

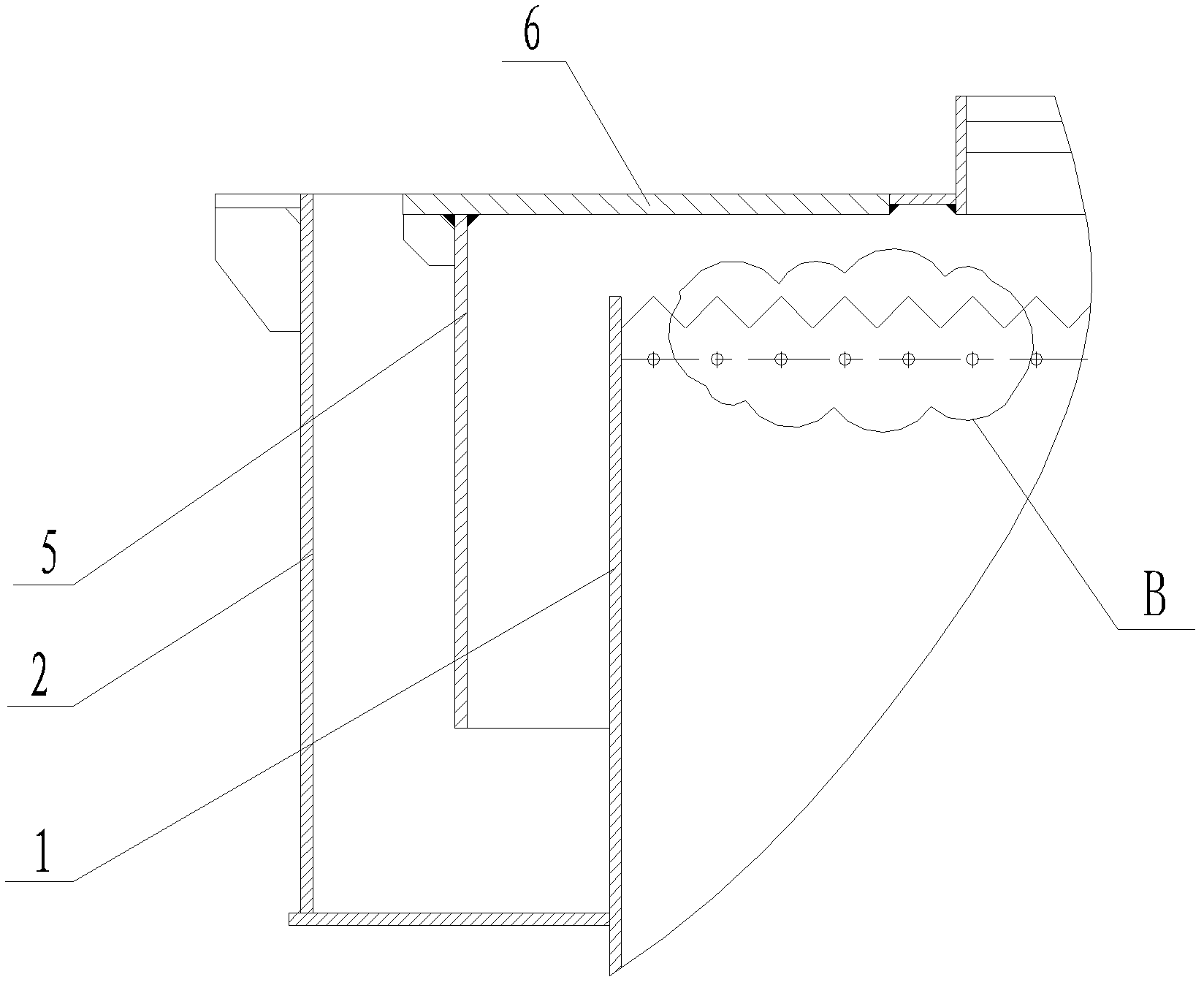

[0074] Such as figure 1 As shown, the converter primary dust removal system of the present invention includes a rapid overflow cooling tower 200 and an adjustable venturi tube 100 , and the middle and lower part of the rapid overflow cooling tower 200 is connected to the adjustable venturi tube 100 through a connecting elbow 300 . Such as figure 2 As shown, the top of the tower body 1 of the rapid overflow cooling tower 200 is provided with an overflow water tank 2 whose cross section around the outer wall of the tower body 1 is circular, and the top of the overflow water tank 2 is higher than the top of the tower body 1, and the overflow Water is housed in the water flow tank 2, and the water in the overflow water tank 2 can overflow into the tower body 1 from the top edge of the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com