Coaxial different-speed combined paddle reactor

A coaxial allometric, reactor technology, applied in the direction of enzyme production/bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of increasing equipment complexity and equipment processing. The difficulty of the reactor, the decrease of the heat transfer performance of the reactor, and the inability of the material to be removed in time, to achieve the effect of easy adjustment of operating parameters, promotion of uniform suspension, and efficient use of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

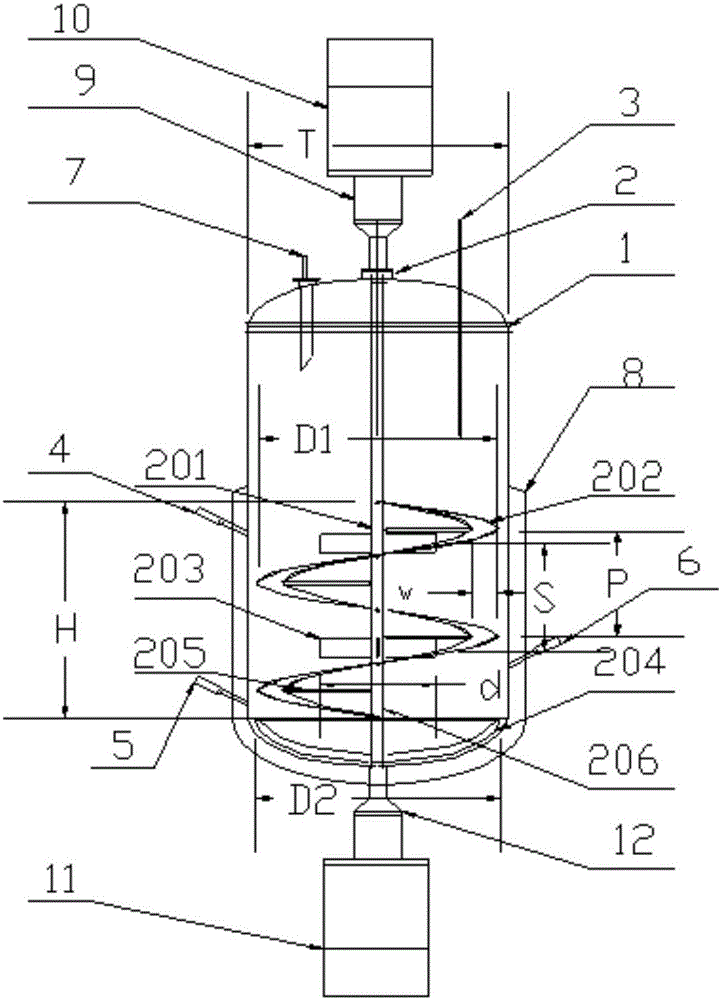

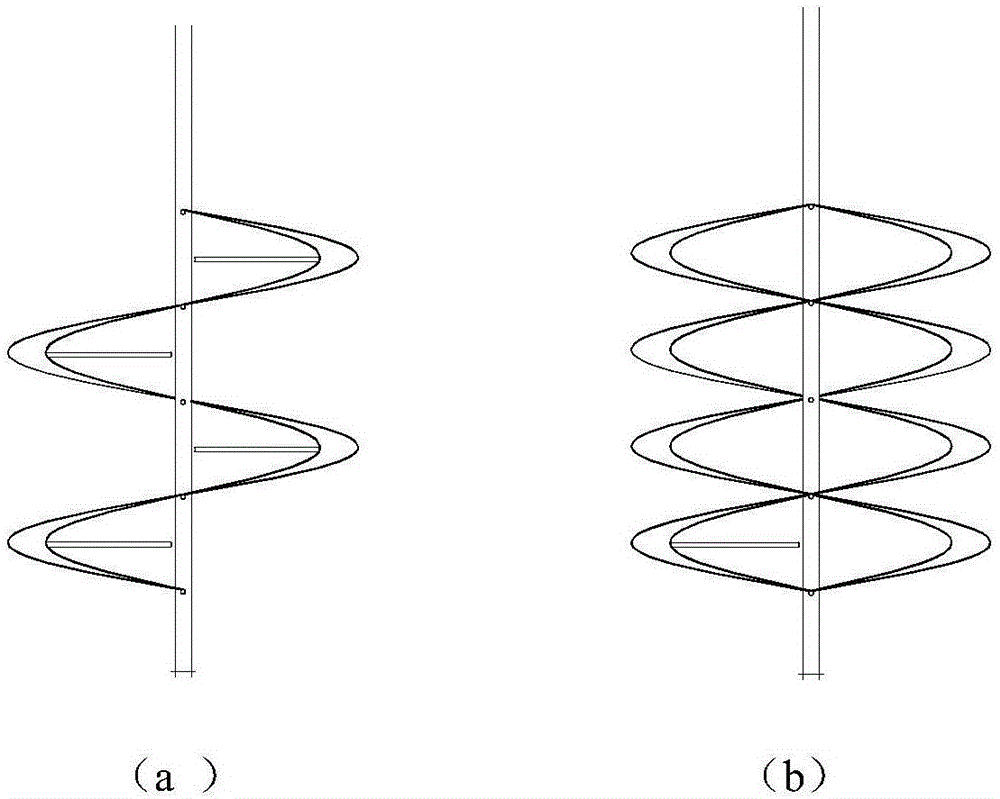

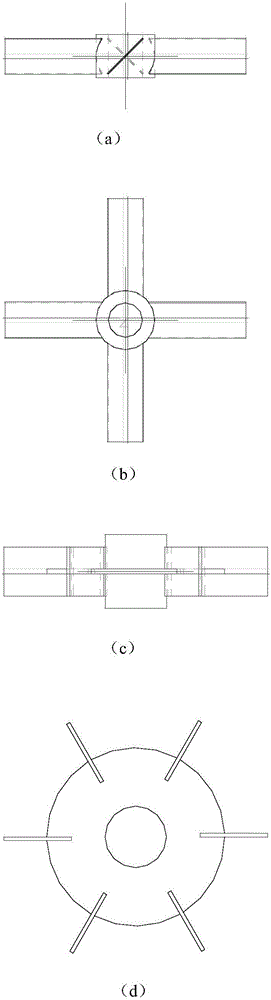

[0036] Such as figure 1 As shown, the coaxial variable speed combined paddle reactor 1 of the present invention includes a stirring device 2, a stirring shaft 201, a ribbon type stirring paddle 202, a lower layer stirring paddle 203, a bottom stirring paddle 204, a support rod 205, and a solid stirring shaft 206 , foam detector 3, pH meter 4, thermocouple 5, dissolved oxygen electrode 6, feeding port 7, steam jacket device 8, first coupler 9, first motor 10, second motor 11, second coupler 12 . Stirring device 2 is axially installed in reactor 1, and stirring device 2 comprises a spiral ribbon type stirring paddle 202 that spirals around stirring shaft 201 from top to bottom, and one is positioned at reactor bottom and is installed on solid stirring shaft 206. Lower floor stirring paddle 203. The ribbon-type stirring paddle 202 is fixed on the stirring shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com