Steamer feeding robot

A robot and feeding mechanism technology, applied in conveyors, mechanical conveyors, loading/unloading, etc., can solve the problems of uneven heating of materials, easy material jamming, material accumulation, etc., and achieve uniform dosage, small impulse, and uniform materials as much as possible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

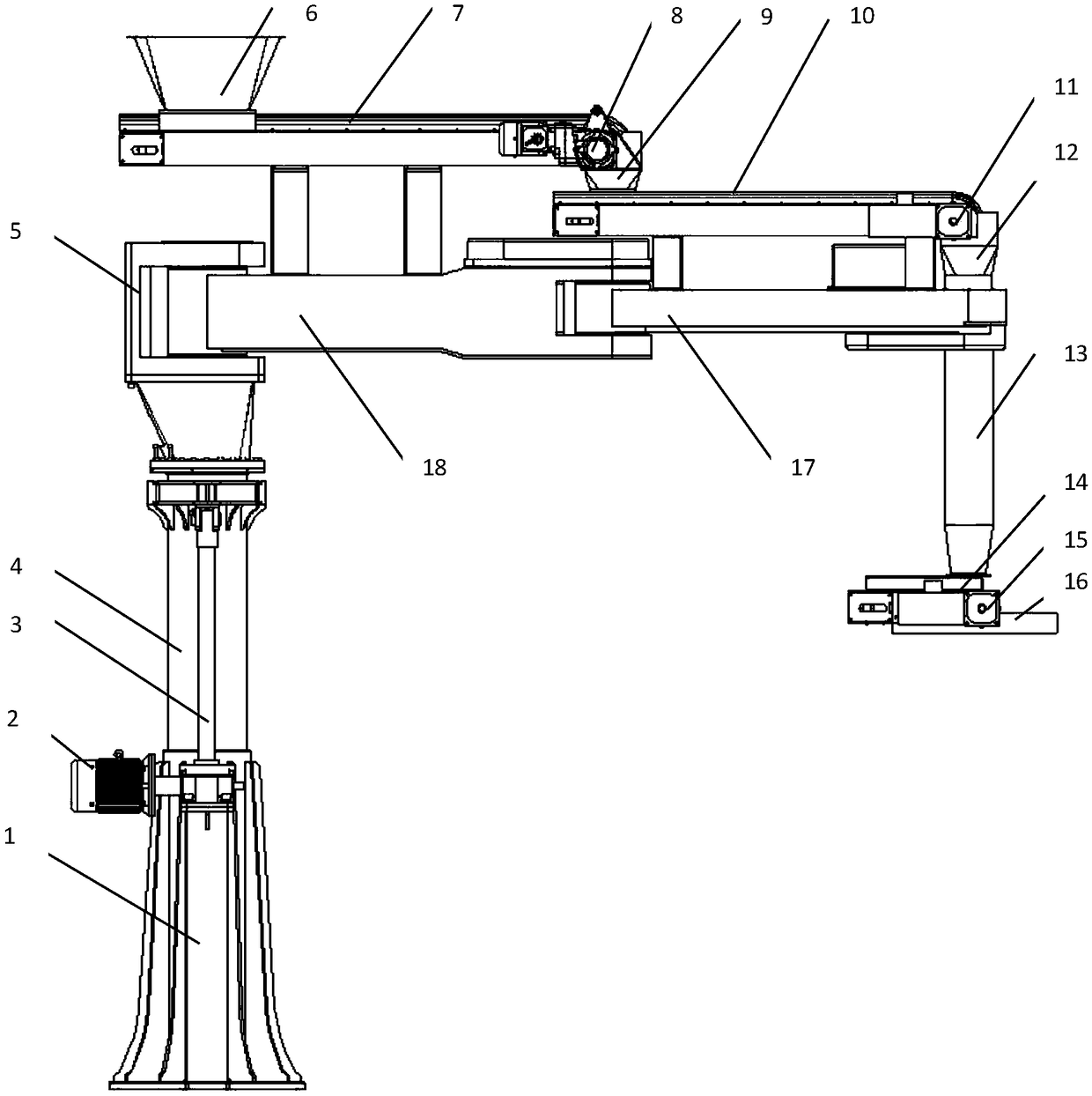

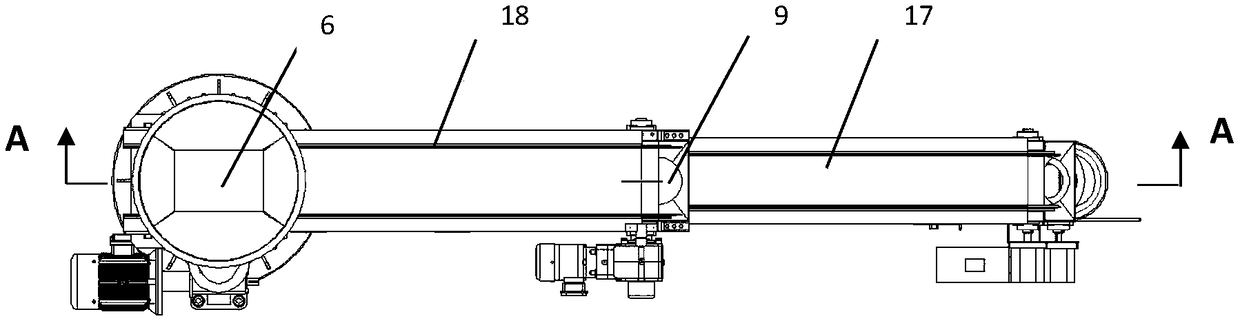

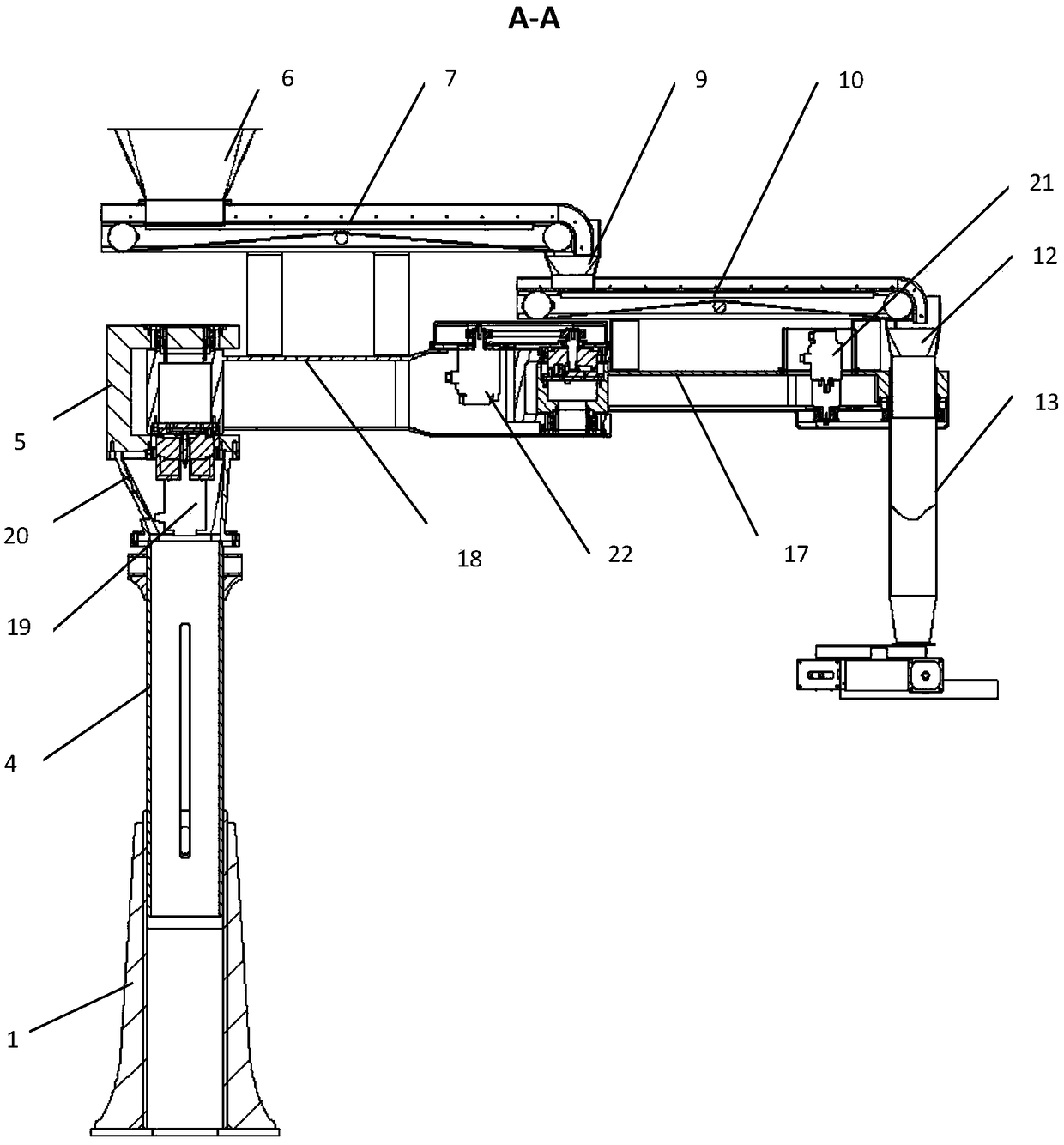

[0027] Such as Figure 1-Figure 5 As shown, the upper robot includes a base 1, a lifting drive mechanism, a lifting column 4, a boom 18, a small arm 17, a primary feeding mechanism, and a secondary feeding mechanism. The lifting column 4 is driven and installed on the base 1 for the lifting drive mechanism. In order to drive the lifting column 3 to move up and down to adapt to the change of the height of the fermented grains in the retort barrel, the top of the lifting column 4 is connected to one end of the boom 18 through the boom rotation mechanism, and the other end of the boom 18 is connected to the bottom arm through the boom rotation mechanism. 17 connection, the first-level feeding mechanism is installed on the upper part of the boom 18, and the second-level feeding mechanism is installed on the upper part of the forearm 17. Both the first-level feeding mechanism and the second-level feeding mechanism use timing belts for material transportation. Carry out material tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com