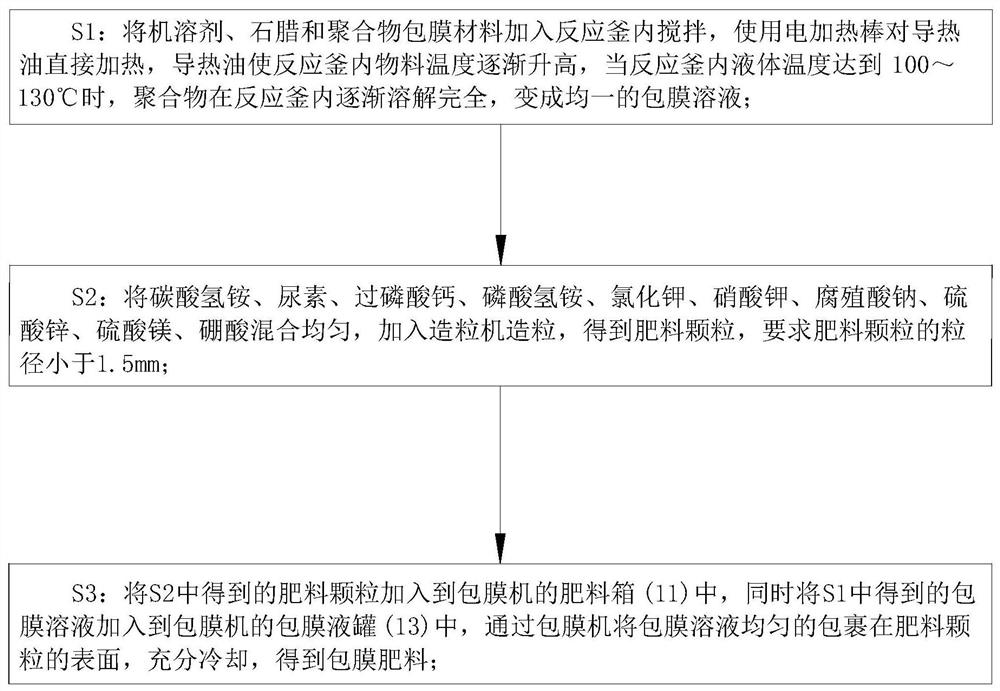

Fertilizer coating process

A fertilizer coating and coating technology, which is applied to organic fertilizers, inorganic fertilizers, ammonium salt fertilizers, etc., can solve the problems of poor film thickness uniformity, difficulty in controlling the thickness of the coating, and difficulty in controlling the fertilizer effect time of coated fertilizers. To achieve the effect of improving quality stability, improving coating efficiency and realizing effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

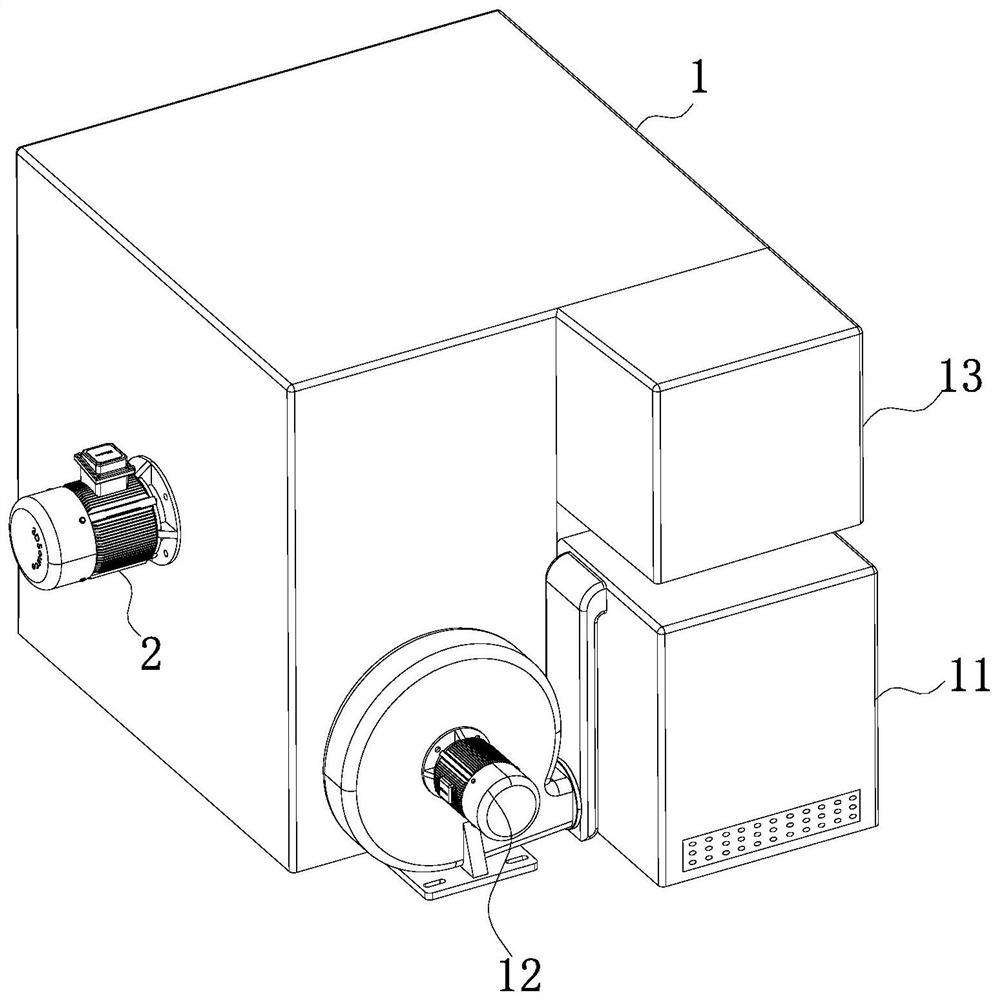

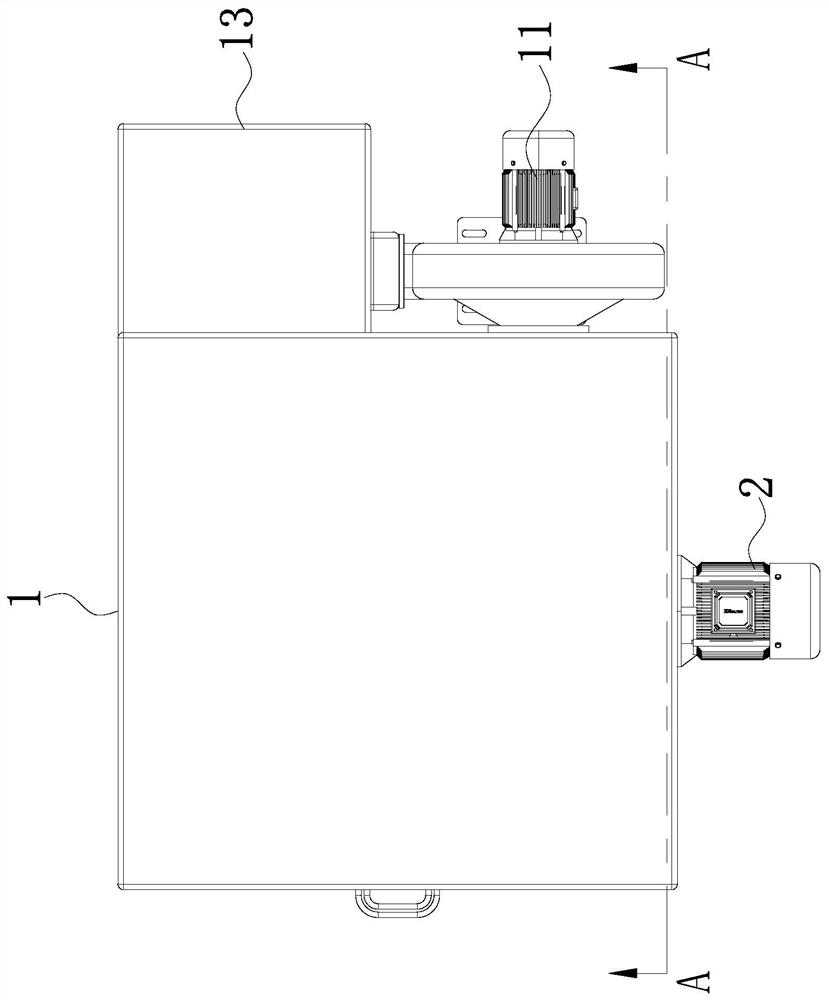

Examples

Embodiment approach

[0048] As an embodiment of the present invention, uniformly arranged second push rods 213 are firmly connected between the control plate 212 and the second guide block 211; Arranged third ejector pin 214;

[0049] During work, by arranging the second push rod 213 and the third push rod 214, the control plate 212 can be driven to move by the second push rod 213, and the movement of the scraper 27 can be driven by the third guide rod to realize the movement of the control plate 212 and the scraper. The position adjustment of the plate 27, the position adjustment of the control plate 212 can effectively control the film thickness of the coating solution on the surface of the coating sticky plate 24, to meet different coating thickness requirements, and the position adjustment of the scraper 27 can control the scraping Plate 27 carries out function switching, when not fully contacting between scraper 27 and coating adhesive plate 24, scraper 27 plays the effect of scraping off the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com