Uniform dispersion equipment for coating production

A uniform dispersion and equipment technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of easy sticking of raw materials to the inner wall of the dispersion tank, waste of resources, increase of labor intensity, etc., to prevent waste of raw material resources, The effect of reducing workload and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

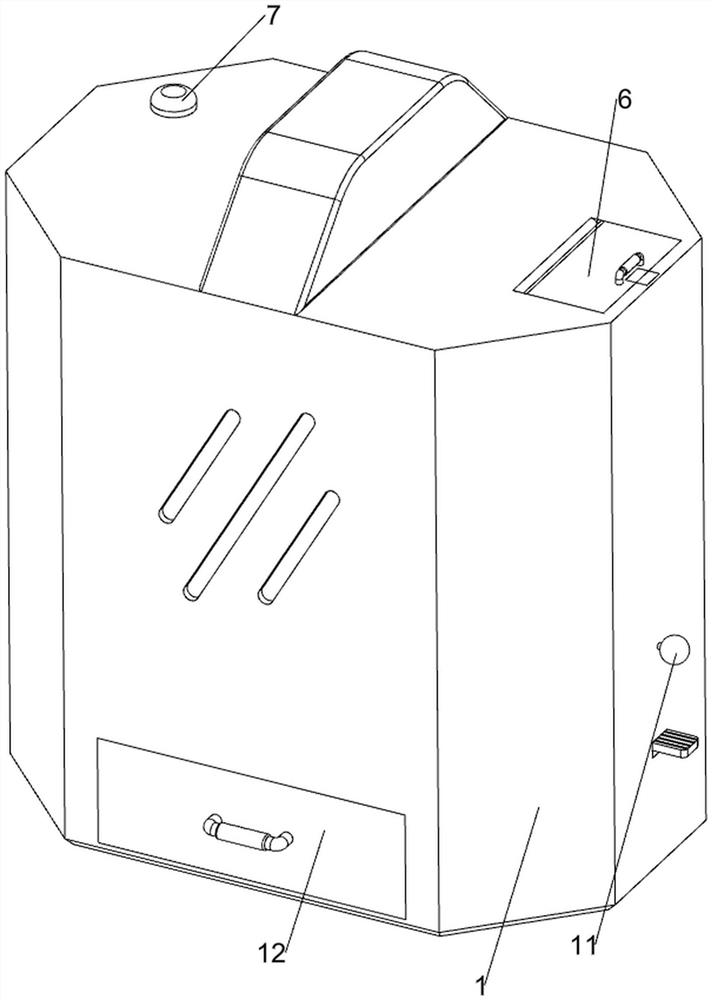

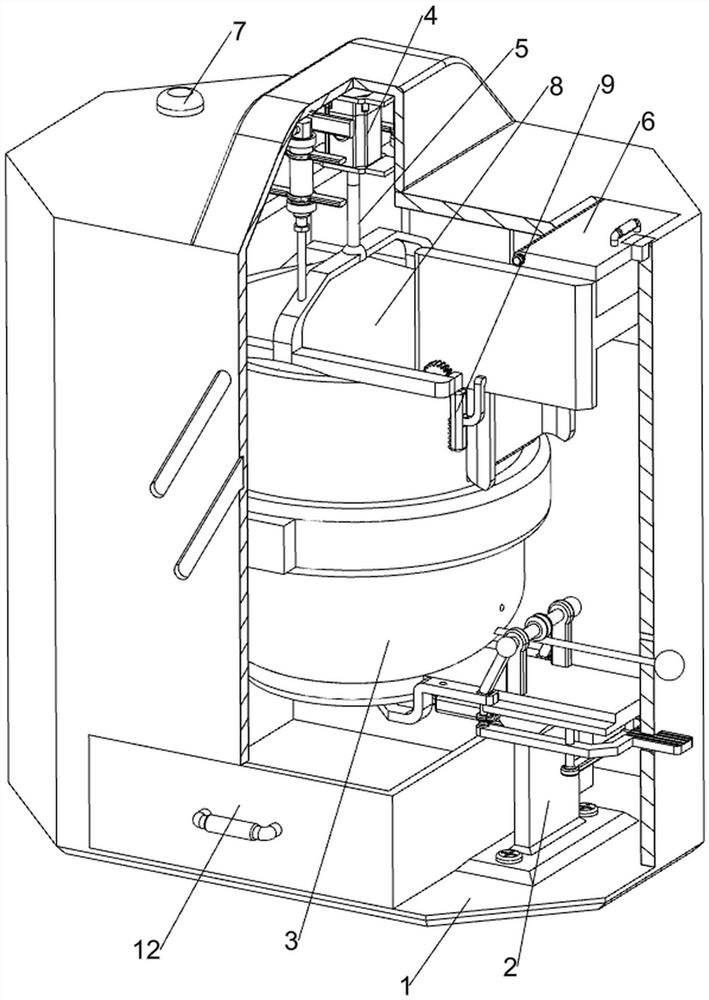

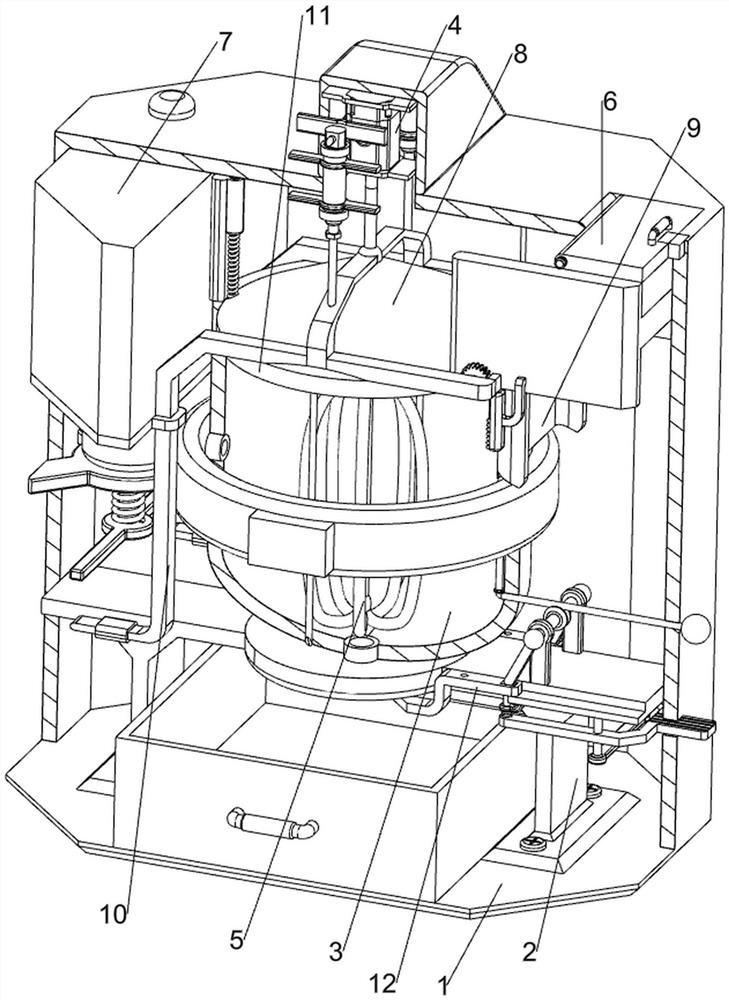

[0037] A uniform dispersion equipment for coating production, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, it includes a casing 1, a bracket 2, a storage tank 3, a servo motor 4, a stirring paddle 5, an opening and closing mechanism 6, and an adding mechanism 7. A storage tank 3 is installed between the inner sides of the housing 1, a servo motor 4 is installed in the middle of the upper side of the housing 1, and a stirring paddle 5 is connected to the output shaft of the servo motor 4. The lower side of the stirring paddle 5 is located inside the storage tank 3, and the top of the housing 1 An opening and closing mechanism 6 is arranged on the right side, and an adding mechanism 7 is installed on the upper left side inside the casing 1 .

[0038] The opening and closing mechanism 6 includes a cover plate 61, a magnet block 62, a first rotating shaft 63 and a first torsion spring 64. The right side of the...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 with Figure 18 As shown, it also includes a splash-proof assembly 8. The splash-proof assembly 8 includes a cylinder 81, a connecting rod 82 and a splash guard 83. A cylinder 81 is installed symmetrically front and back in the middle of the upper side of the interior of the housing 1. Between the lower side of the telescopic rod of the cylinder 81 A connecting rod 82 is connected, and the connecting rod 82 is rotationally connected with the stirring paddle 5 , and a splash guard 83 is installed at the bottom of the connecting rod 82 .

[0043] Also includes a guide assembly 9, the guide assembly 9 includes an engaging rod 91, a fixed plate 92, a guide rail 93, a swivel seat 94, a second rotating shaft 95, a gear 96, a rack 97, a guide plate 98 and a second torsion spring 99, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com