Sealing device for material bucket capable of stirring concrete

A sealing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, engine sealing, etc., can solve the problems of inconvenient fixing and transition of the mixer, inability to promote large-scale use, and no mixing function, etc., to improve the mixing effect , easy to clean, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

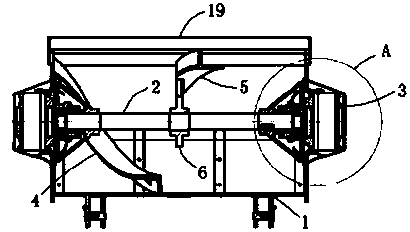

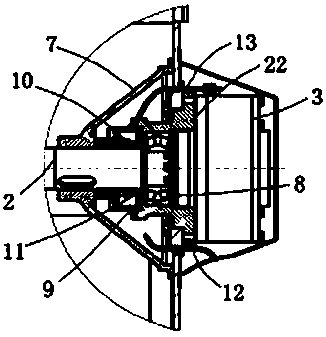

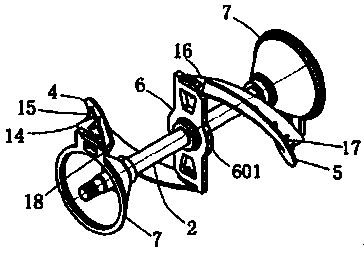

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 , Figure 5 Commonly shown, the present invention discloses a hopper capable of mixing concrete, which includes a bucket body 1, a stirring shaft 2 driven by a hydraulic motor 3 is installed in rotation in the bucket body 1, and a middle dial wheel is fixedly installed in the middle of the stirring shaft 2 6. The left helical blade 4 and the right helical blade 5 with opposite rotations are arranged on both sides of the middle dial 6 respectively, and the end of the left helical blade 4 and the right helical blade 5 close to the middle dial 6 is fixedly installed on the middle dial 6 , the other end of the left helical blade 4 is fixedly mounted on the left end of the stirring shaft 2, the other end of the right helical blade 5 is fixedly mounted on the right end of the stirring shaft 2, and a left passing material is provided between the left helical blade 4 and the stirring shaft 2 There is a gap between the ri...

Embodiment 2

[0037] The present invention also discloses a loader capable of mixing concrete. The loader includes the hopper capable of mixing concrete described in Embodiment 1. Through the use of the hopper, the loader also has many beneficial features. Effect.

[0038] As mentioned above, the present invention provides a hopper capable of mixing concrete and a loader including the hopper, which have many beneficial technical effects, thus having good application potential and industrial production prospect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com