High-efficiency cement stirring device

A mixing device and high-efficiency technology, applied in the field of mixing machinery, can solve problems such as low work efficiency, waste of raw materials, and volume reduction, and achieve the effects of reducing the use of manpower, avoiding unnecessary waste of raw materials, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

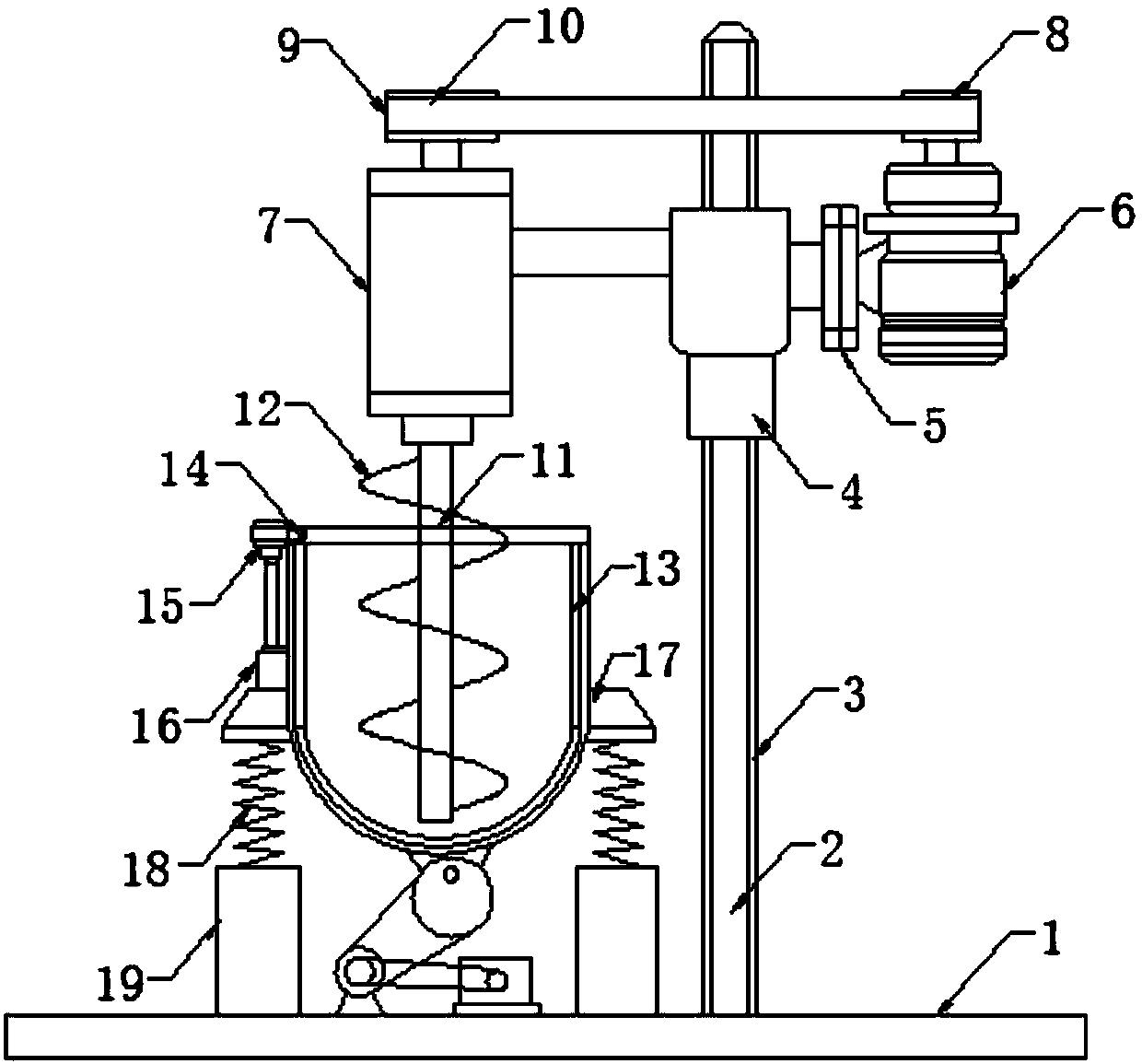

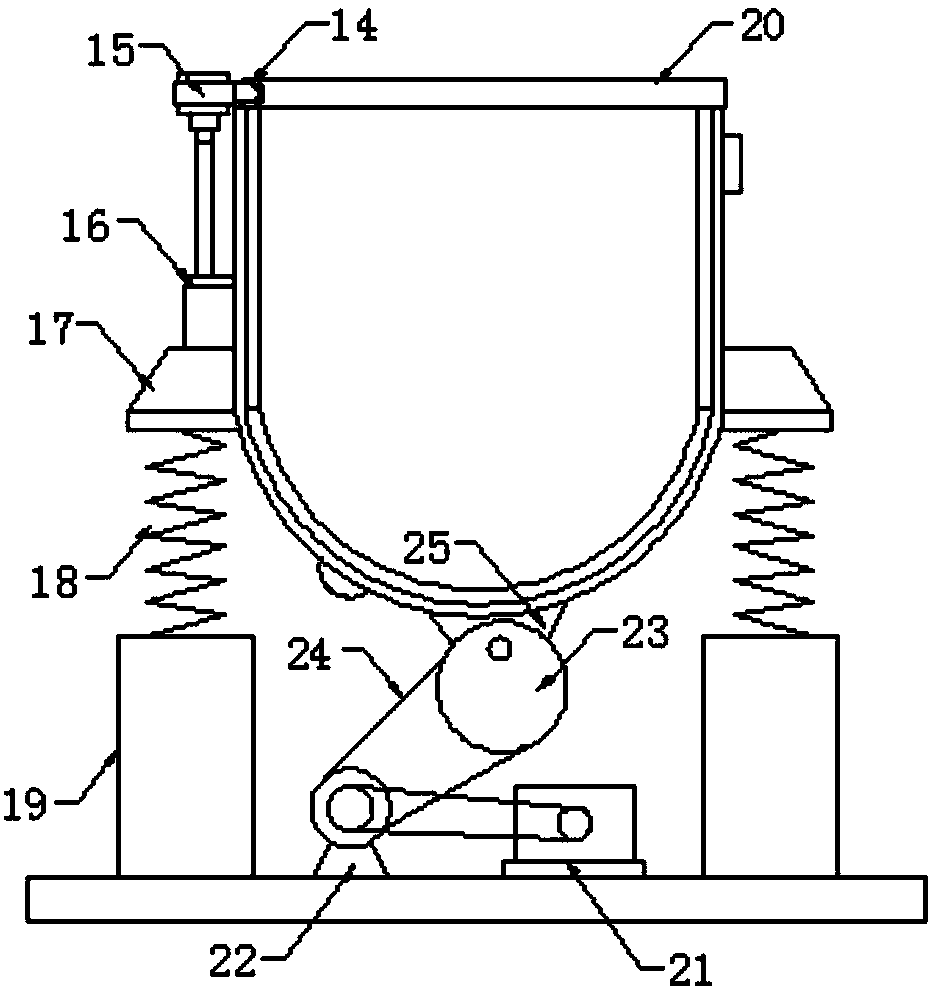

[0021] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a high-efficiency cement mixing device, including a base 1, a column 2, a longitudinal slide rail 3, a lifting sliding sleeve 4, a connecting piece 5, a stirring motor 6, a headstock 7, Driving wheel 8, transmission belt 9, driven wheel 10, main shaft 11, stirring fan blade 12, cylinder body 13, movable shaft 14, lifting joint 15, hydraulic cylinder 16, positioning sleeve 17, limit spring 18, support seat 19, cylinder cover 20. Drive motor 21, drive wheel 22, eccentric wheel 23, belt 24 and positioning member 25, base 1 is fixed with column 2, and vertical slide rail 3 is provided on column 2, and column 2 is installed by sliding through longitudinal slide rail 3 The lifting sliding sleeve 4, the two ends of the lifting sliding sleeve 4 are respectively fixedly connected with the stirring motor 6 and the main shaft box 7 through the connecting piece 5, the output end of the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com