Premixing stirring system for cake stirring machine

A mixing system and a whisk technology, applied to the structural components of mixing/kneading machinery, mixing/kneading with vertical installation tools, etc., can solve the problems of easy adhesion on the inner wall of the mixing tank, high viscosity of raw materials, and uneven mixing and other problems, to achieve the effect of easy cleaning, uniform premixing and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

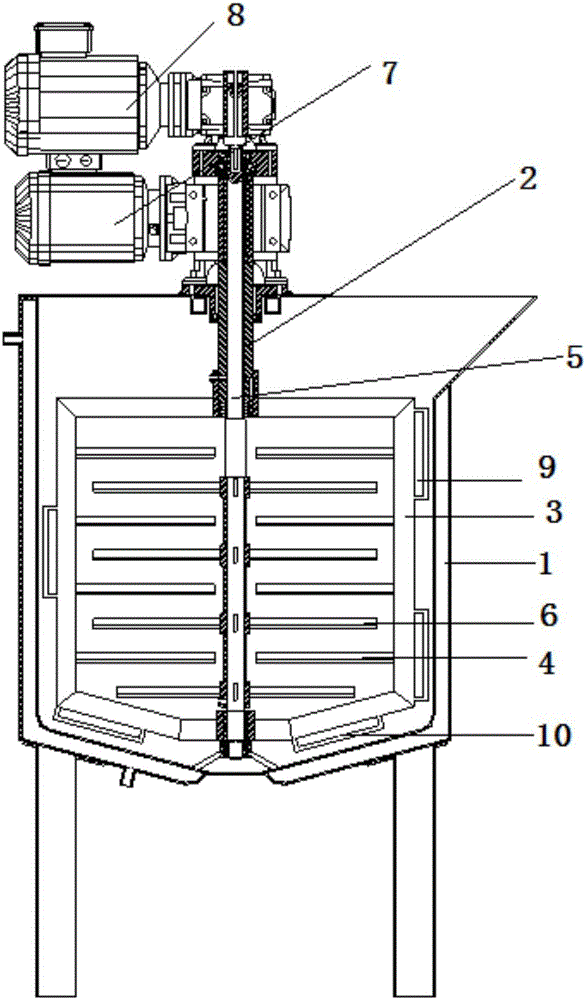

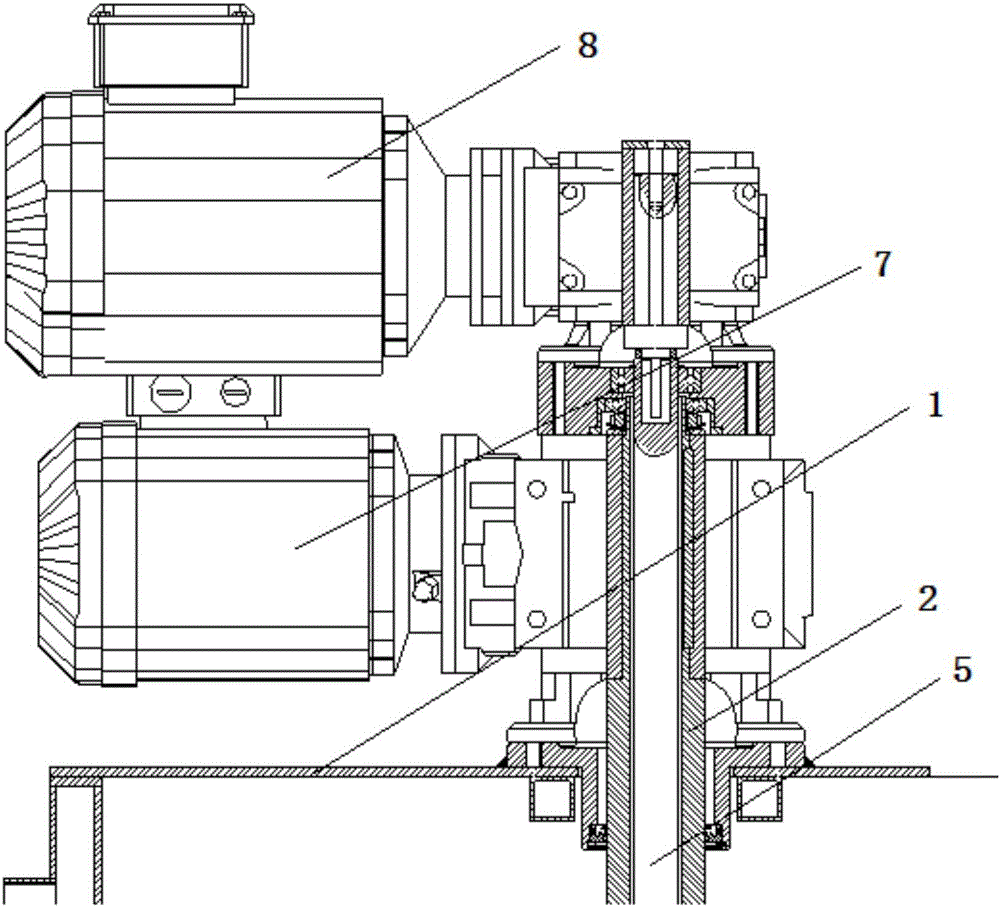

[0015] See attached picture.

[0016] A premixing system for a cake whipping machine, comprising a stirring tank body 1, a vertical hollow outer rotating shaft 2 is mounted on the top of the stirring tank body 1, and a vertical hollow outer rotating shaft 2 is fixedly installed on the lower part of the outer rotating shaft 2 to match the inner wall shape of the stirring tank body. The matching stirring frame blade 3 has a plurality of outer transverse blades 4 fixedly distributed on the inner side of the stirring frame blade 3; the inner rotating shaft 5 is installed in the rotation of the outer rotating shaft 2, and the lower end of the inner rotating shaft 5 protrudes from the outer rotating shaft and runs through the stirring frame type The blades are rotated and installed in the mounting holes at the bottom of the stirring frame blades. The inner shafts are provided with a plurality of inner transverse blades 6 spaced apart from the outer transverse blades 4; 7,8 control r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com