Material online moisture measuring device and measuring method thereof

A technology of measuring device and measuring method, which is applied in the direction of using microwave to test moisture content, material size control, non-electric variable control, etc., can solve the problems of reduced measurement accuracy, difference in moisture value of microwave moisture meter, difficulty in moisture measurement, etc. Achieve the effect of reducing the thickness difference, the measurement value jumping is small, and the measurement accuracy is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

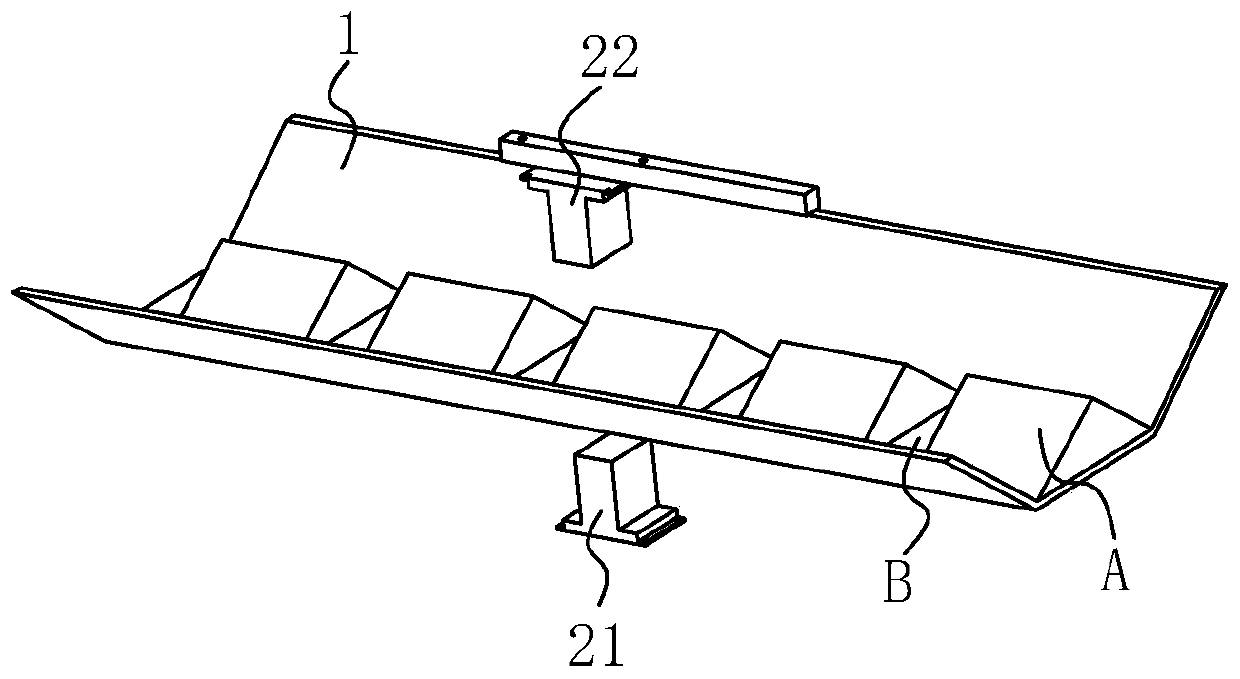

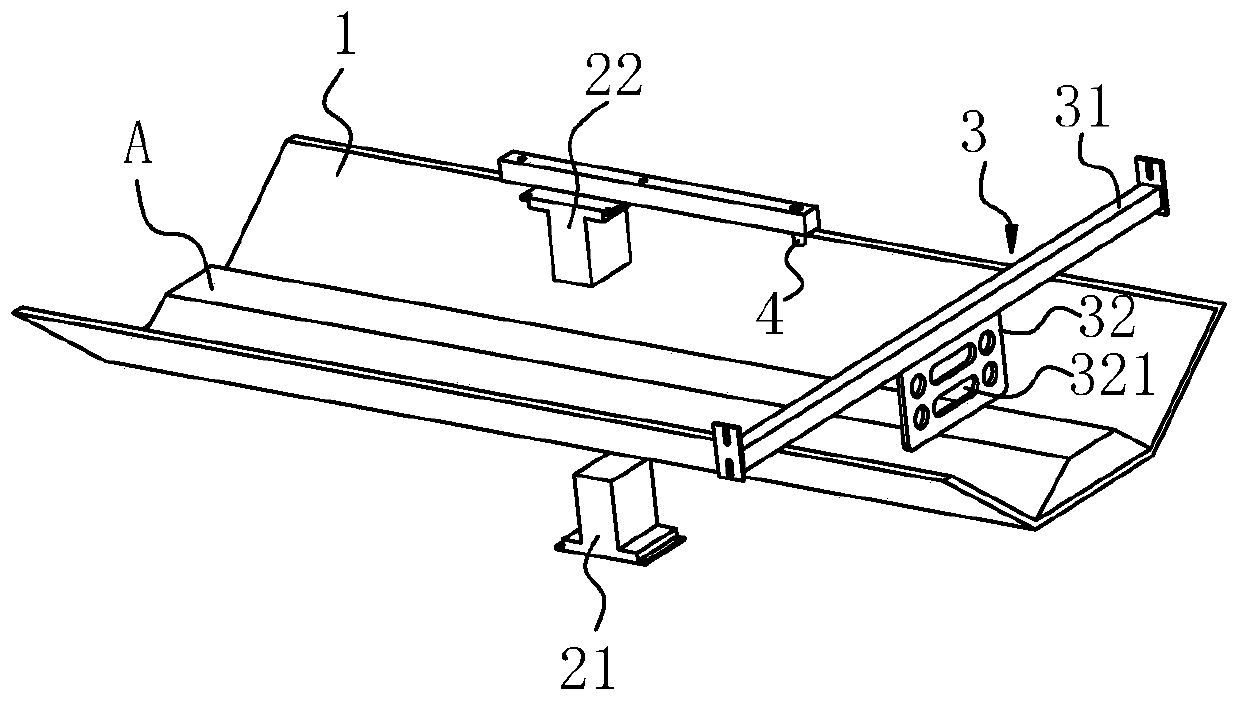

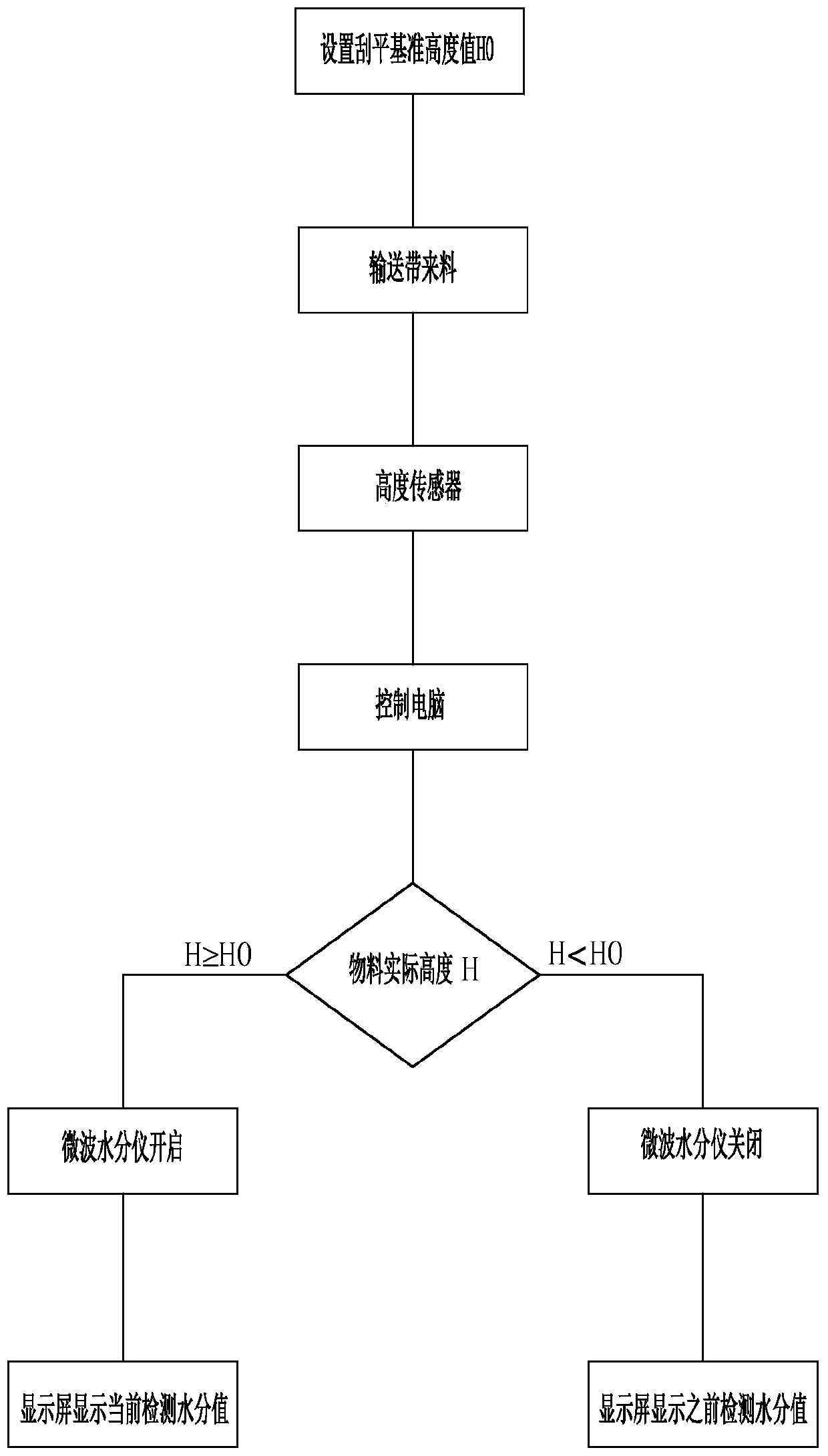

[0030] Such as figure 2 As shown, the material online moisture measurement device of the embodiment of the present invention includes: a microwave moisture meter, a scraper component 3 and a material height detection element 4, and the microwave moisture meter and the material height detection element 4 are respectively connected to the control computer by communication.

[0031] Wherein, the microwave moisture meter includes a microwave transmitter 21 arranged between the upper belt 1 and the lower belt (not specifically shown in the figure) of the material conveyor belt, and a microwave receiver 22 arranged above the upper belt 1. The location of the receiver 21 corresponds to the position of the microwave receiver 22.

[0032] Wherein, the scraping member 3 is arranged above the upper belt 1 and located upstream of the microwave receiver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com