Traffic transport vehicle facilitating loading and unloading

A transport vehicle and transportation technology, applied in the field of transportation, can solve the problems of sticky sludge, sticky box surface, large amount of cleaning work for transport vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

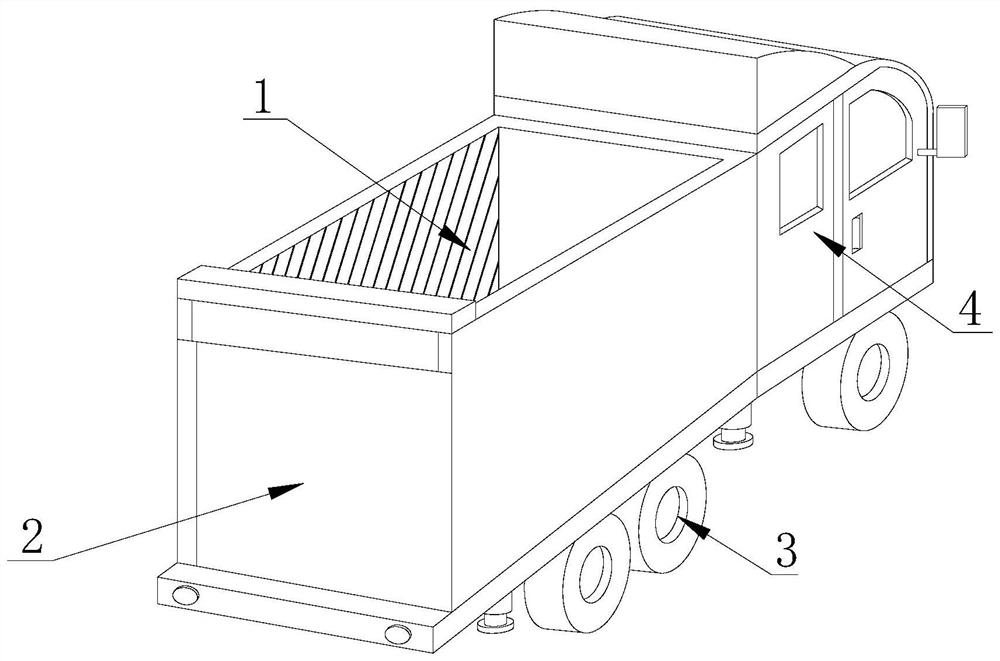

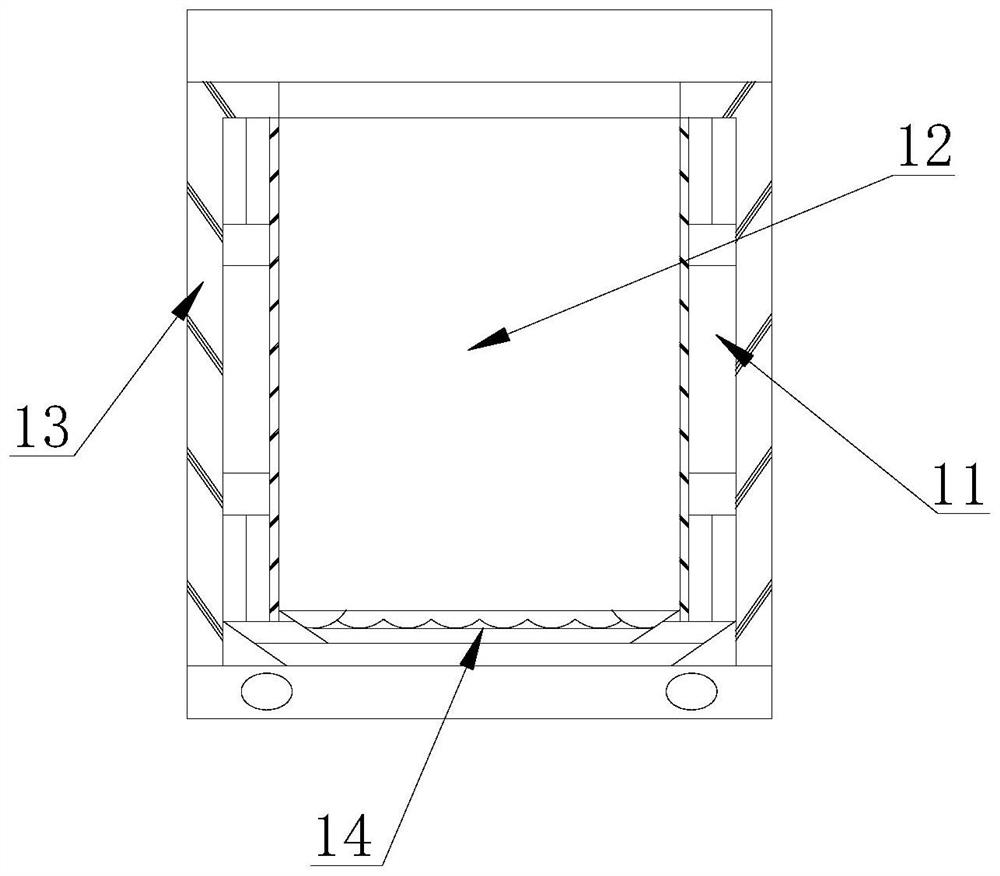

[0030] Append figure 1 Adherent Figure 5 Down:

[0031] Its structure includes a carrier box 1, a partition bonding door 2, a drive wheel 3, a head 4, and the lower surface of the carrier box 1 and the driving wheel 3 top gap, the drive wheel 3 upper end with the head 4 lower end gap, The front of the head 4 is fitted with the top of the carrier box 1, and the carrier box 1 is hinged to the left side of the partition bonding door 2, the carrier box 1 including the cleaning plate 11, carrier 4, box wall 13, The storage seat 14, the inner side of the cleaning plate 11 is embodied in the inner surface of the box wall 13, and the lower end of the inner wall of the box wall 13 is engaged with the storage seat 14, and the surface of the accommodating seat 14 is fitted with the carrying bin 12 four-week activity. Sides on both sides of the carrier 12 and the surface gap between the cleaning plate 11.

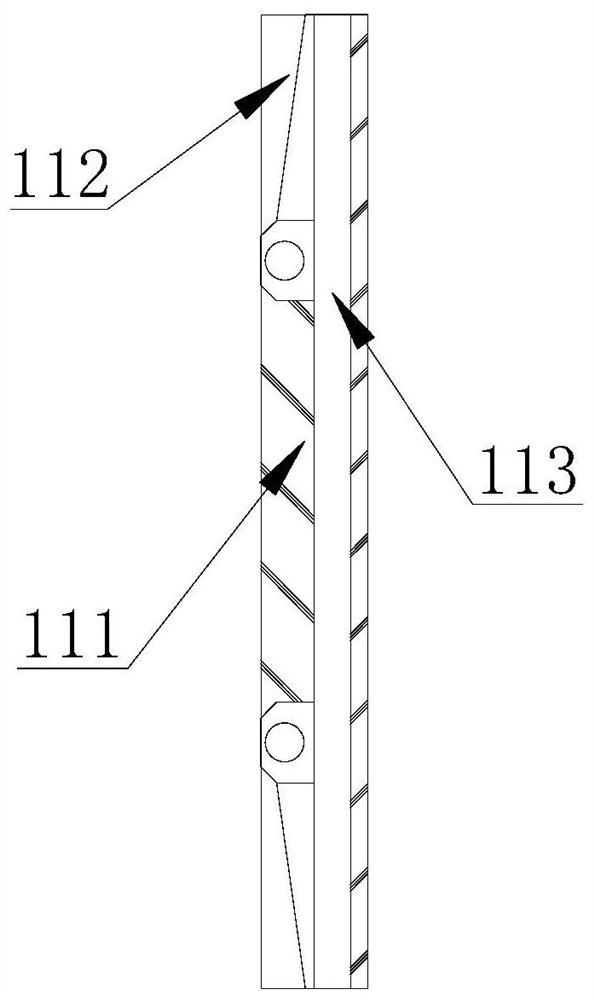

[0032] Wherein, the cleaning plate 11 includes a wiper plate 111, a card slot 112, an ...

Embodiment 2

[0038] Append Image 6 Adherent Figure 9 Down:

[0039] Wherein, the receiving seat 14 includes a collecting plate 141, a tank 142, a spring post 143, and a two side engaging the inner groove 142 on both sides, the lower end of the ink solid slot 142 and the spring post 143 surface. The gap is fitted, the spring post 143 is fitted with the lower end activity of the collecting plate 141, and the spring post 143 is provided, which is distributed under the left and right ends of the tank 142, and the collecting plate 141 is gapped, and the collecting plate 141 It is conducive to preventing residual sludge from splashing after the sludge unloading.

[0040] Wherein, the collecting plate 141 includes a stirring ring B1, a drainage plate B2, a fixed plug B3, a filter screen B4, and the agitating ring B1 is embedded with the lower surface of the filter screen B4, the upper end of the filter screen B4 Mixed with the lower end of the drainage plate B2, and the entire bolt is fixed to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com