Hot-rolled U-rib double-sided welding method

A technology of double-sided welding and welding area, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low welding efficiency, insufficient weld penetration, large welding deformation, etc., to achieve high welding efficiency, The effect of improving construction efficiency and reducing welding material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

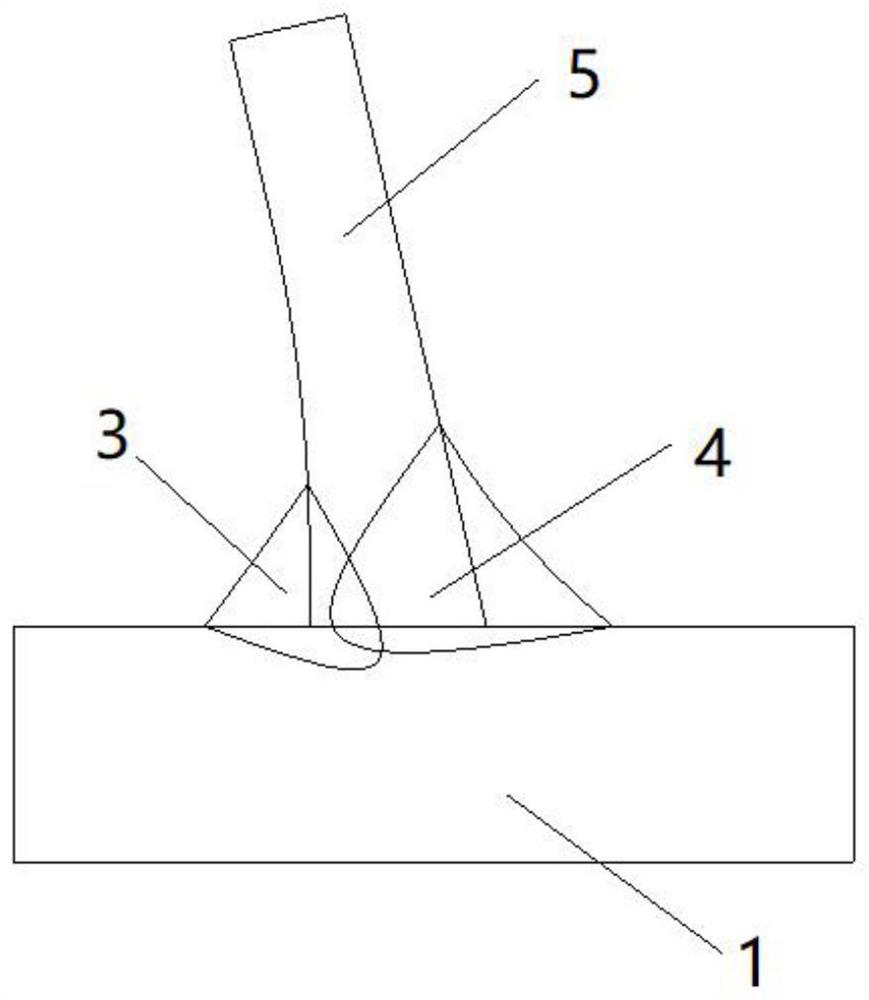

[0039] Such as figure 1 As shown, this embodiment provides a method for double-sided welding of hot-rolled U-ribs. The welding end thickness is 12 mm and the variable-section hot-rolled U-ribs 5 are as follows:

[0040] (1) Grind the area to be welded of the U rib, and polish and clean the rust, oil, paint, oxide layer, etc. of the area to be welded of the U rib until the area to be welded of the U rib is flat to facilitate welding.

[0041] (2) Grinding the area to be welded on the bridge deck 1 and the range of 20-30mm on both sides, grinding and cleaning the rust, oil, paint, oxide layer, etc. on the area to be welded on the bridge deck 1 until the area to be welded on the bridge deck 1 Flatten for subsequent steps.

[0042] (3) Put the U rib upside down on the bridge deck 1, so that the area to be welded of the U rib is attached to the surface of the area to be welded of the bridge deck 1, and the area to be welded of the U rib does not need to be grooved.

[0043] (4) W...

Embodiment 2

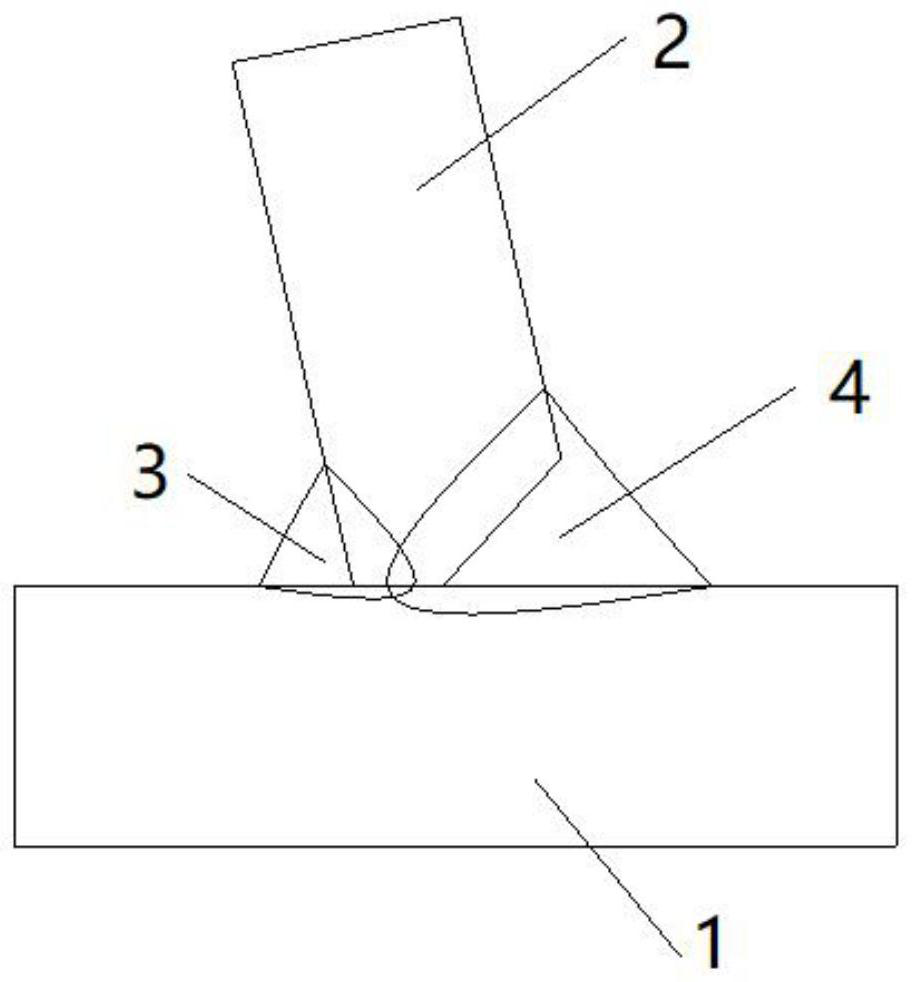

[0052] Such as figure 2 As shown, this embodiment provides a method for double-sided welding of hot-rolled U-ribs. The thickness of the welding end is 16 mm and the variable-section hot-rolled U-ribs 2 are as follows:

[0053] (1) Polish the area to be welded of the U rib, and polish and clean the rust, oil, paint, oxide layer, etc. on the area to be welded of the U rib until the area to be welded of the U rib is flat. This step is consistent with step (1) of Example 1.

[0054] (2) Grinding the area to be welded on the bridge deck 1 and the range of 20-30mm on both sides, grinding and cleaning the rust, oil, paint, oxide layer, etc. on the area to be welded on the bridge deck 1 until the area to be welded on the bridge deck 1 Flat. This step is consistent with step (2) of Example 1.

[0055] (3) Make a welding groove on the outside of the U rib to be welded. The welding area is in contact with the surface of the area to be welded on the bridge deck 1 .

[0056] (4) Weld...

Embodiment 3

[0065] This embodiment provides a double-sided welding method for hot-rolled U-ribs. This embodiment is consistent with Embodiment 2, except that step (6) is changed.

[0066] (6) The front wire adopts DC power supply, the control welding current is 910A, the welding voltage is 38.2V, the welding speed is 680mm / min, the rear wire welding current is 690A, the welding voltage is 34.7V, and the welding speed is 680mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com