Quick preparation method of metal surface boronizing layer

A metal surface, boronizing layer technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of chemical heat treatment surface infiltration layer preparation, etc., to shorten the preparation time, overcome the high temperature , the effect of broad application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

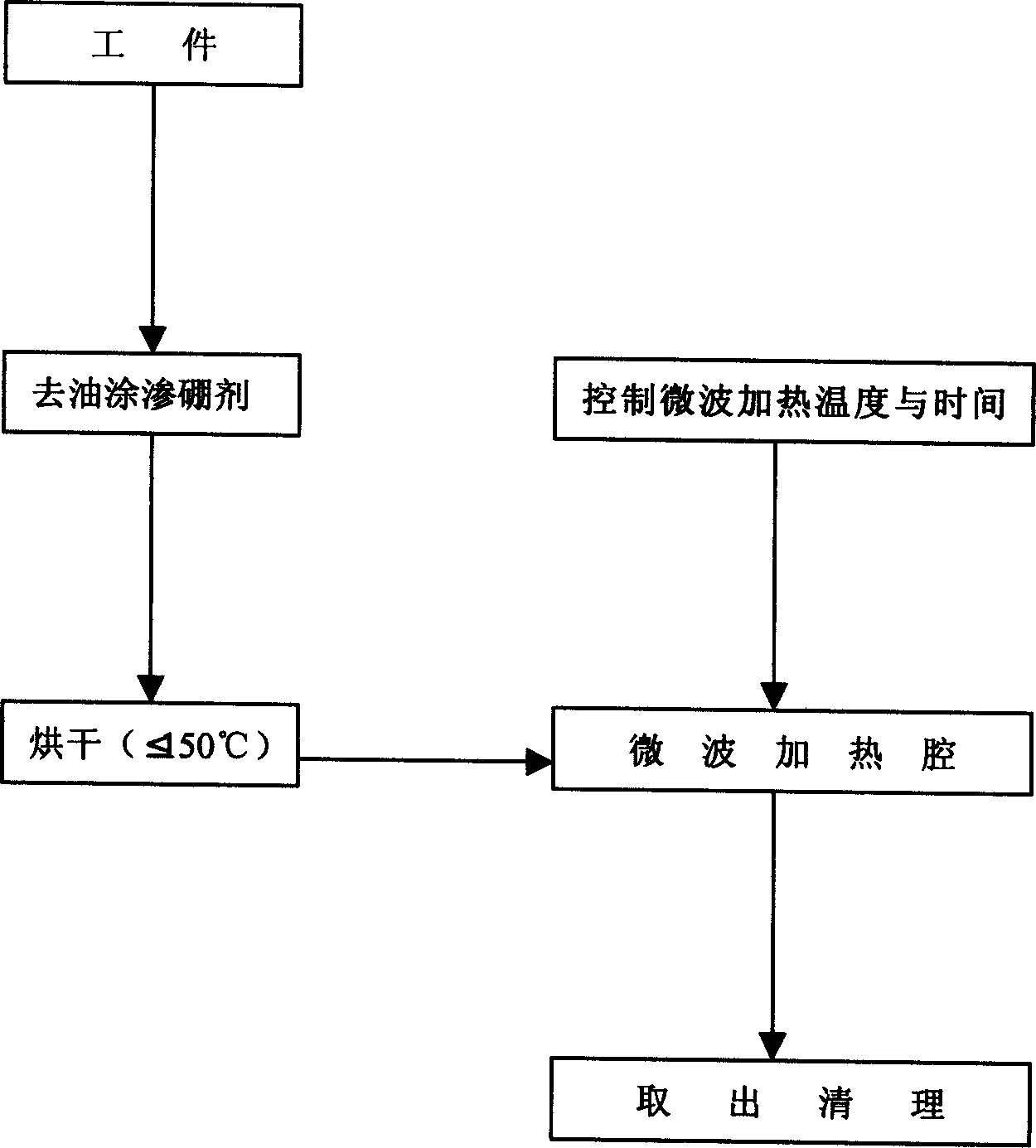

Method used

Image

Examples

Embodiment 1

[0024] The quality is 50% borax + 10% SiC + 10% KCl + 20% Na 2 AlFe 6 +5%B 4 C+5%Cr 2 o 3 Composition of Paste Boronizing Agent Wraps 35 # Put the carbon steel in a ceramic crucible with a diameter of 50mm and put it into the heating chamber of a microwave oven at a temperature of 850°C, heat and keep it for 1 hour to obtain a boronizing layer with a thickness of 30μm, and the structure is complete and compact. X-ray analysis shows that the boronizing layer is Fe 2 B, FeB duplex structure.

Embodiment 2

[0026] Adopt the same pasty boronizing agent of embodiment 1 to wrap 25 # Carbon steel is placed in a ceramic crucible with a diameter of 50mm and put into a microwave oven heating chamber at a temperature of 850°C, and heated for 0.5 hours to obtain a boronizing layer with a thickness of about 10μm.

Embodiment 3

[0028] With a mass of 40% B 4 C+50%CaF 2 +10%Na 2 SiF 6 The composed boronizing agent is uniformly prepared and made into a paste with rosin 30% + alcohol 70% alcohol, and evenly coated on the workpiece that has been degreased and derusted. The coating thickness is greater than 2mm, and put into a ceramic crucible Place it in a microwave heating chamber and keep it warm at 700-950°C for 0.5-1.5 hours to obtain a boronizing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com