Experimental device of gas-sensitive temperature property test of carbon nano tube sensor and method

A technology of carbon nanotubes and temperature characteristics, applied in the direction of material resistance, etc., can solve the problems of inability to test the temperature characteristics of carbon nanotubes, lack of temperature adjustment parts, and inability to test temperature characteristics, and achieves easy popularization and application, improved sensitivity, and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

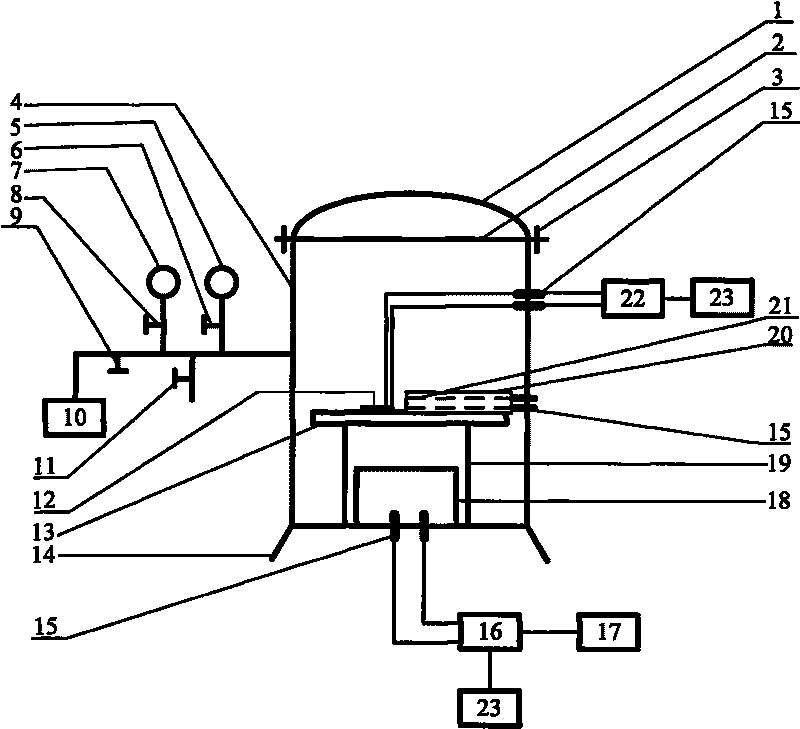

[0025] Such as figure 1As shown, an experimental device for testing the gas-sensitive temperature characteristics of a carbon nanotube sensor mainly includes a cylinder body 4, a vacuum pump 10, an AC contactor 16, a digital display regulator 17, an electric furnace 18, a thermal resistance 21, an impedance analyzer 22, etc. . The cylinder body 4 is cylindrical with a closed bottom, made of stainless steel, with a wall thickness of 6mm, an inner diameter of 100mm, and a height of 100mm. The sealing ring 2 is connected with the cylinder body 4 through the screw nut 3, so that the inside of the cylinder body 4 becomes a sealed space to withstand the internal and external air pressure and the corrosiveness of the measured gas during the experiment. The cylinder body 4 passes through the tripod 14 placed on the ground. The vacuum pump 10 communicates with one side of the cylinder through the air guide tube and through the ball valve 9, the vacuum gauge 7 and the vacuum gauge nee...

Embodiment 2

[0027] Such as figure 1 As shown, an experimental device for testing the gas-sensitive temperature characteristics of a carbon nanotube sensor is the same as in Example 1, wherein: the wall thickness of the cylinder 4 is 4mm, the inner diameter is 80mm, and the height is 80mm, and the power of the electric furnace 18 is 500W.

Embodiment 3

[0029] Such as figure 1 As shown, an experimental device for testing the gas-sensing temperature characteristics of a carbon nanotube sensor is the same as in Example 1, wherein: the wall thickness of the cylinder 4 is 5mm, the inner diameter is 90mm, and the height is 90mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com