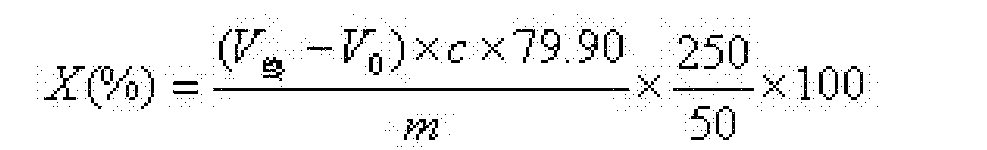

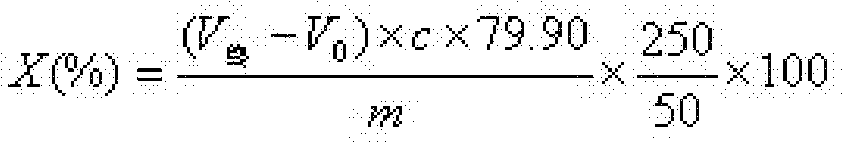

Method for detecting content of bromine in fire retardant through automatic potentiometric titration

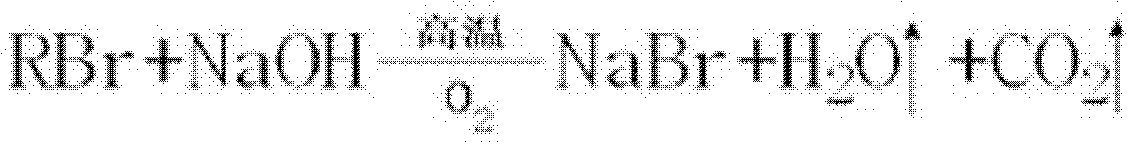

A potentiometric titration and potentiometric titration technology, applied in the direction of electrochemical variables of materials, can solve the problems of inevitable introduction of chlorine atoms, difficulty in achieving flame retardant performance, etc., and achieve the effects of low requirements, simple drugs and instruments, and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Sample pretreatment

[0034] (1) Use a clean and dry nickel crucible to directly weigh 0.3g of the sample (accurate to 0.0002g), then add 1 drop of OP-10 emulsifier and 10 drops of potassium hydroxide solution, soak the sample completely and shake it evenly;

[0035] (2) Add about 1g of ground sodium carbonate to cover the surface of the sample, then evenly add 3.5g of ground solid sodium hydroxide on the surface, cover the lid (not tightly closed), and put it on the pressure-regulated electric furnace with refractory bricks Slowly heat (with the sample coming out as the degree) to dissolve potassium hydroxide and sodium hydroxide;

[0036] (3) Continue to heat up to melt and absorb the sample in the alkali solution until there is no white powdery solid in the crucible;

[0037] (4) Turn off the electric furnace to cool the sample. Add 1 / 2 of the crucible high water, heat to dissolve all the molten material in water, transfer it to a 100ml beaker, clean the nickel...

Embodiment 2

[0053] (1) Sample pretreatment

[0054] (1) Use a clean and dry nickel crucible to directly weigh 0.4g of the sample (accurate to 0.0002g), then add 2 drops of emulsifier and 15 drops of sodium hydroxide solution, soak the sample completely and shake it evenly;

[0055] (2) Add 2g of ground sodium carbonate to cover the surface of the sample, then add 3.5g of ground solid sodium hydroxide evenly on the surface, cover the lid (not tightly closed), and slowly Slowly heat (with the sample not coming out as the degree) to dissolve potassium hydroxide and sodium hydroxide;

[0056] (3) Continue to heat up to melt and absorb the sample in the alkali solution until there is no white powdery solid in the crucible;

[0057] (4) Turn off the electric furnace to cool the sample. Add 1 / 3 of the crucible high water, heat to dissolve all the molten material in water, transfer it to a 200ml beaker, clean the nickel crucible and lid, and transfer the washing liquid into the beaker;

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com