Method for producing spongy iron by direct reduction of dry coal powder gasification and hot coal gas fine ore fluidized bed

A technology of ore fluidized bed and dry coal powder, which is applied in the field of metallurgy and ironmaking, can solve the problems of being unable to get rid of the dependence on massive carbon-containing raw materials, increasing energy and raw material costs, and low gasification temperature of hot furnaces, etc., to achieve resource utilization. And the effect of improving energy utilization rate, reducing energy consumption, and high gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

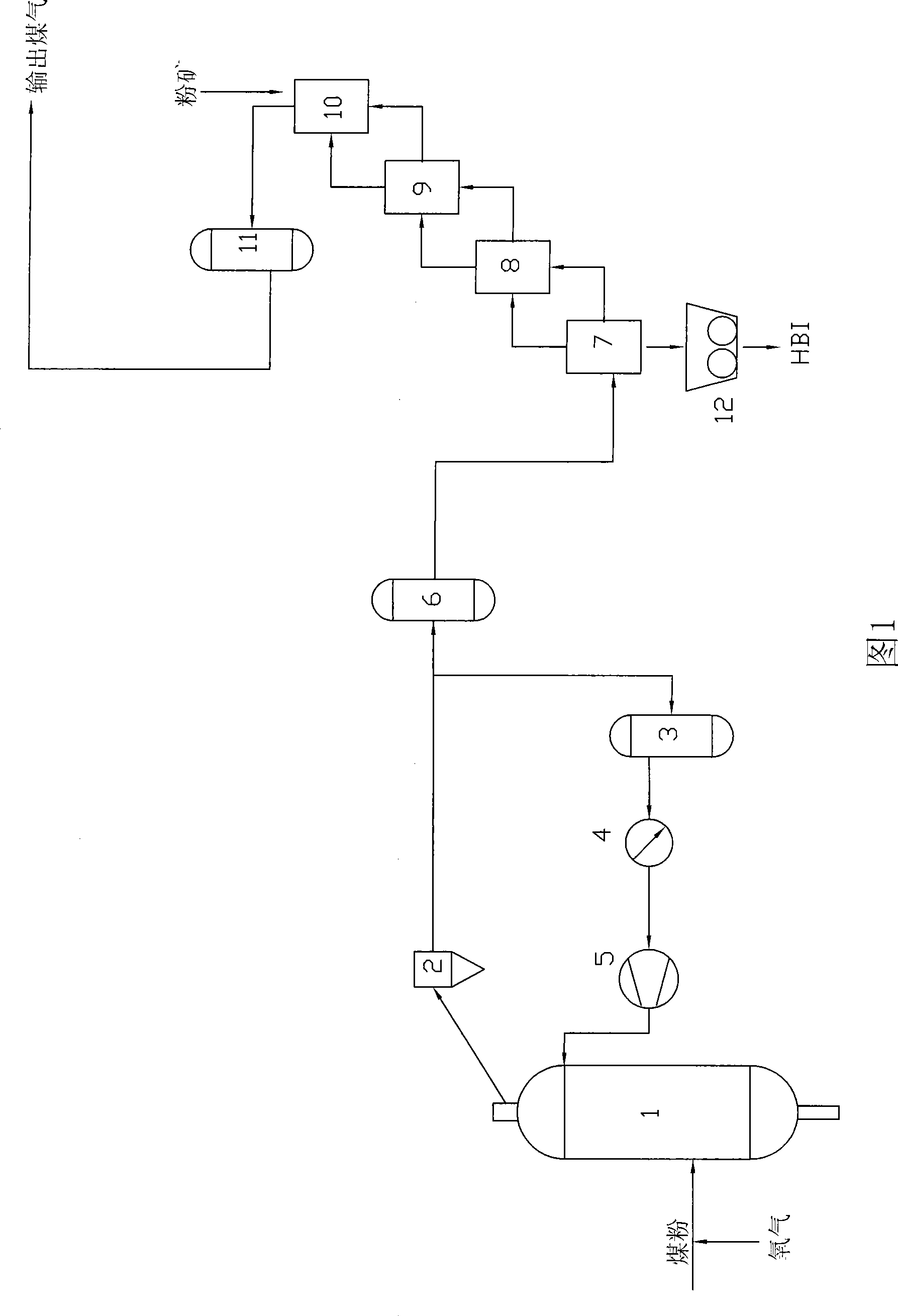

[0065] Referring to Fig. 1, the dry coal gasification thermal coal gas powdered ore fluidized bed direct reduction process of the present invention produces sponge iron, the pulverized coal that is ground to a particle size of less than 0.1mm and dried to a moisture content of less than 2% is passed through a dry coal gasification furnace 1. The burner is sprayed into the furnace together with oxygen, and a violent gasification reaction occurs under high temperature and high pressure, and the organic matter in the coal is converted into CO, H 2 , CO 2 and H 2 O, the ash is turned into slag at high temperature and then discharged from the gasifier.

[0066] Since the actual gasification reaction temperature in the furnace is as high as 1500-1600°C, the high-temperature coal gas produced by gasification is quenched by cold gas at the top of the gasification furnace to 900-950°C and then leaves the gasifier; the hot gas at 900-950°C passes through first The hot cyclone 2 dedust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com