Method for producing spongy iron by direct reduction of dry coal powder gasification and hot coal gas fine ore fluidized bed

A technology of ore fluidized bed and dry coal powder, which is applied in the field of metallurgy and ironmaking, to achieve the effect of improving carbon conversion rate, simple processing equipment and reducing production cost

Inactive Publication Date: 2010-12-01

BAOSHAN IRON & STEEL CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a dry coal gasification hot coal gas powdered ore fluidized bed direct reduction method to produce sponge iron, overcome the limitation of natural gas resources in the existing gas-based method, and use efficient and clean coal gasification technology to produce high-quality Reducing gas: the sensible heat of high-temperature gas is used to provide the energy required for the reduction of iron ore powder, which improves energy utilization and avoids the problem of carbon deposition during the heating process of reducing gas. The sponge iron produced can be directly used in electric furnace steelmaking , superior to traditional blast furnace and direct reduction ironmaking processes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

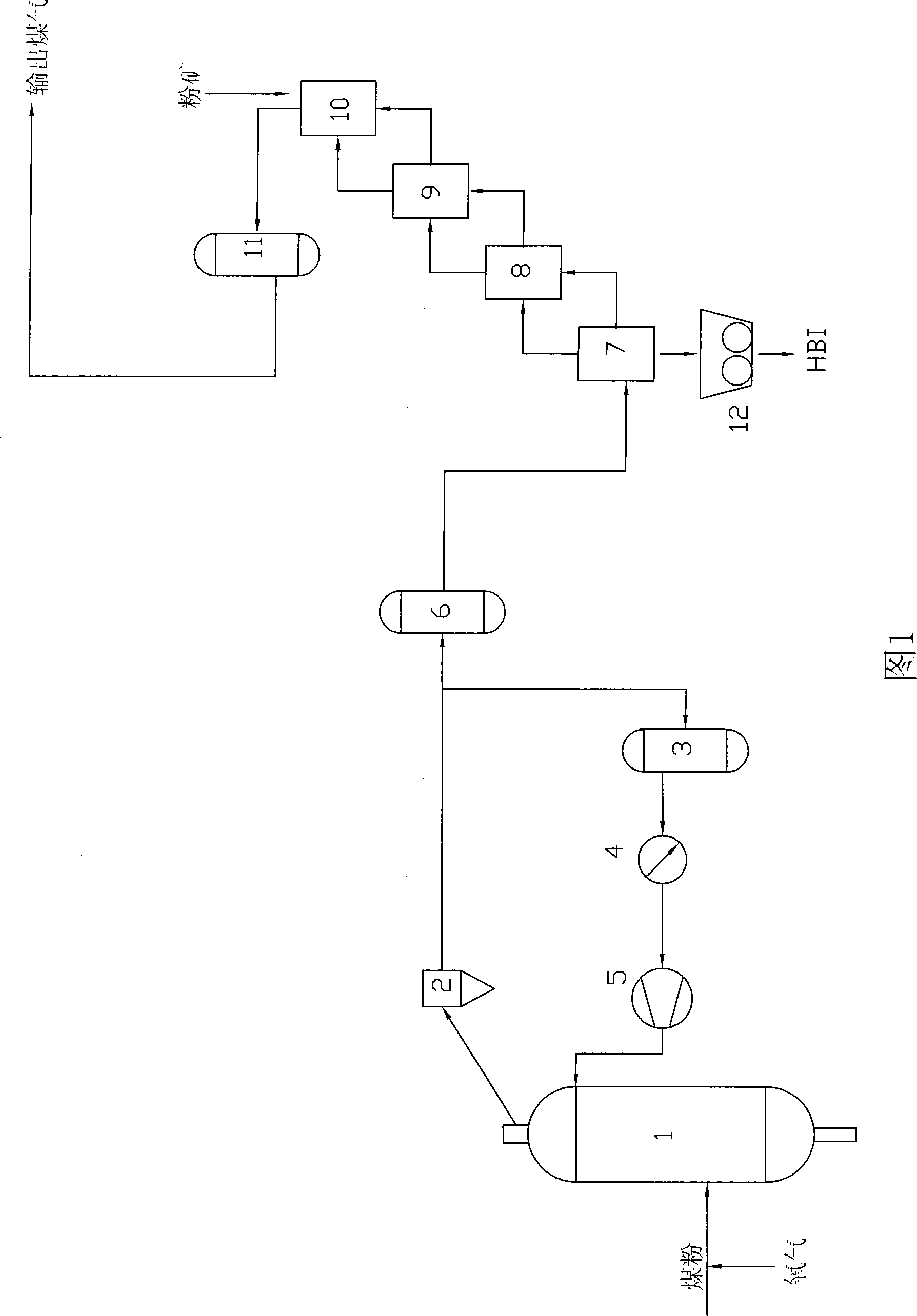

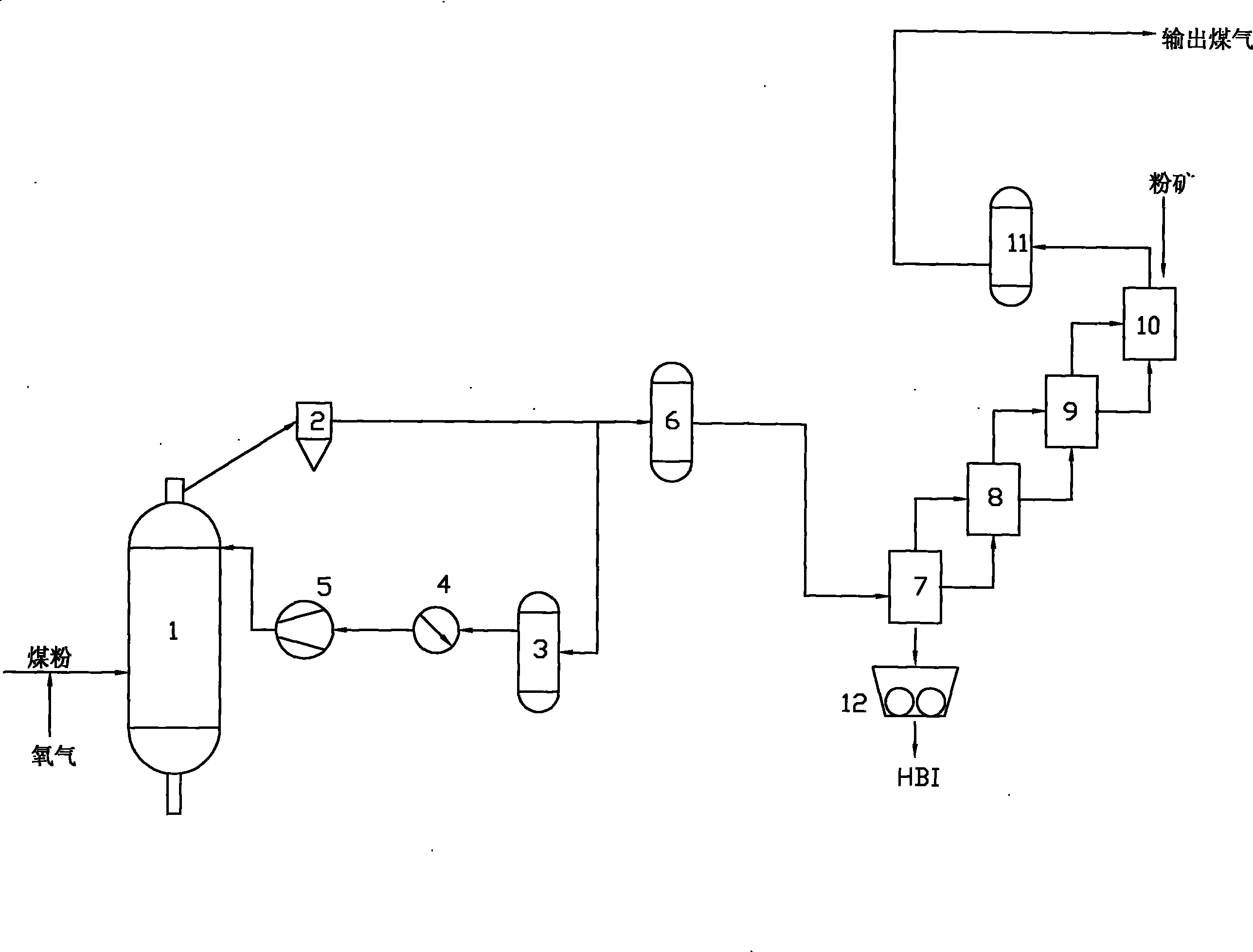

The invention discloses a method for reducing and producing sponge iron directly by a dry coal dust gasified hot coal gas fineore fluidized bed, which comprises the following steps of: a) grinding and drying the feed coal; b) spraying the dry coal dust and pure oxygen into a pressured gasification furnace; c) chilling the hot coal gas at the top of a gasification furnace to be 900 DEG C to 950 DEG C by the cooled coal gas of 30 DEG C to 80 DEG C, then removing dust, and after washing and cooling part of the coal gas to be 30 DEG C to 80 DEG C, which then returns to the top of the gasificationfurnace, chilling the high-temperature coal gas; d) desulfurizing the remaining coal gas which is taken as reducing gas for entering a fluidized bed reactor; and e) introducing the hot coal gas into the last level of the multilevel fluidized bed; and then the coal gas flows in the opposite direction of the iron-containing powder lot; the coal gas flows through all levels of the fluidized bed in the reverse direction and the iron-containing powder lot flows through all levels of the fluidized bed in the forward direction, and then the iron-containing powder lot and the reduced gas countercurrent contact with each other, therefore, the sponge iron is obtained by progressive reduction and carburization. The reduced gas is produced by adopting the technology of gas generation; the energy utilization rate is improved by using the sensible heat of the hot coal gas to provide the energy which is necessary in the hematite reduction; and the generated sponge iron can be used for the electrosmelting of steel directly.

Description

Dry coal gasification hot coal gas powder ore fluidized bed direct reduction method for producing sponge iron technical field The invention belongs to the field of metallurgy and ironmaking, and in particular relates to a method for producing sponge iron by direct reduction of dry coal powder gasification hot coal gas powder ore fluidized bed. Background technique At present, the industrial production technology of direct reduced iron can be divided into two categories: gas-based method and coal-based method. The gas-based method can be divided into two types: shaft furnace direct reduction and fluidized bed direct reduction. Among them, the shaft furnace method is represented by Midrex and HYL processes, and the sponge iron produced by these two methods accounts for more than 80% of the world's total output. The gas-based shaft furnace method has the advantages of mature production technology, reliable equipment, high productivity (volume utilization coefficient of 8-10...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B13/00C22B1/14

CPCY02P10/122

Inventor 钱晖周渝生李肇毅沈红标顾德仁

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com