Cargo handling conveying device

A transmission device and cargo loading and unloading technology, applied in loading/unloading, conveyors, transportation and packaging, etc., can solve the problems of wasting manpower, high handling costs, easy damage of loading and unloading goods, etc., to achieve reduced labor intensity, strong versatility, The effect of improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

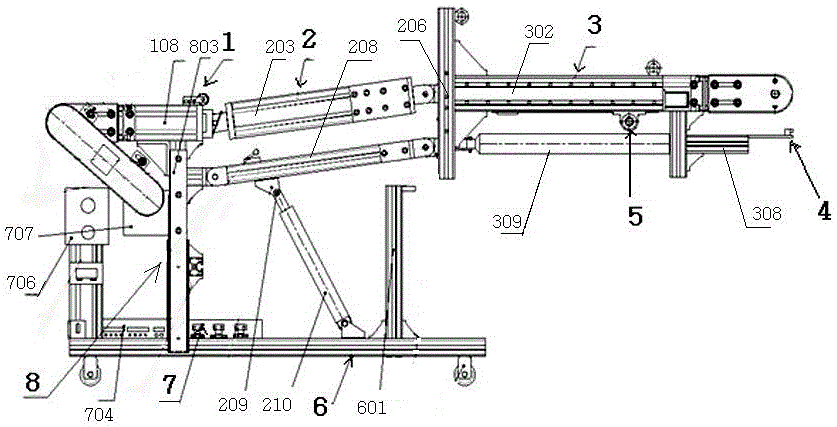

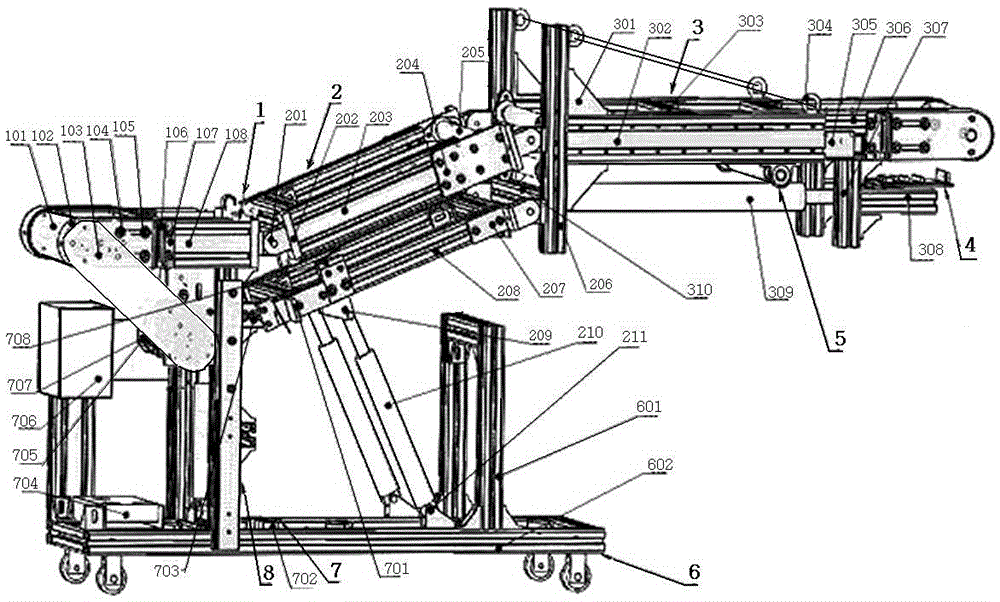

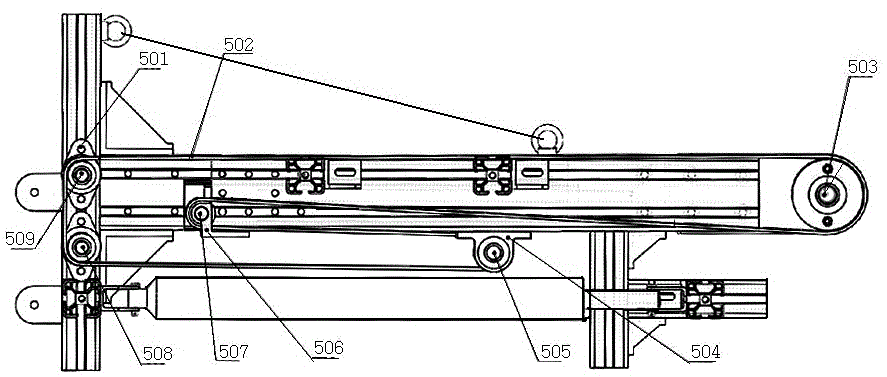

[0019] figure 1 It is a schematic diagram of the front view of the structure of the present invention; it can be seen from the figure that the present invention includes an integral lifting platform 1, an adjustable inclined plane four-bar mechanism 2, a front telescopic plane 3, an automatic following system 4, a belt storage mechanism 5, a frame 6, and a circuit control System 7, lifting slide rail mechanism 8. Integral lifting platform 1, adjustable inclined four-bar mechanism 2, front telescopic plane 3, and belt storage mechanism 5 form a multi-section integrated transmission device; the governor 706 of the circuit control system 7 is located on the upper side of the DC power supply, and the DC power supply is fixed to the frame 6 Connection; overall lifting platform 1, adjustable inclined four-bar mechanism 2, and front telescopic plane 3 are connected by livin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com