Shipping device for port cargoes

A cargo and port technology, applied in the field of port cargo handling machinery and equipment, can solve the problems of long preparation time, high cost of using door cranes, unsuitable for loading and unloading operations, etc., and achieve short adjustment time, cost reduction, and cargo loading efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

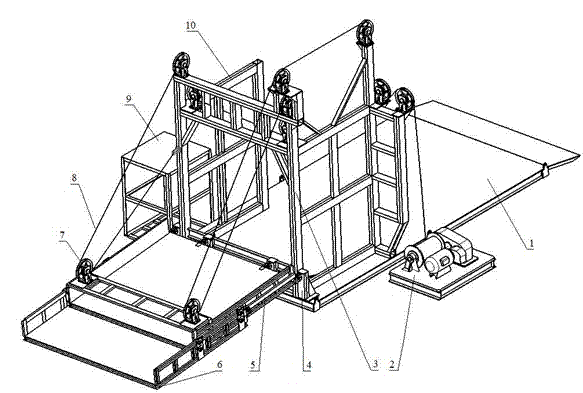

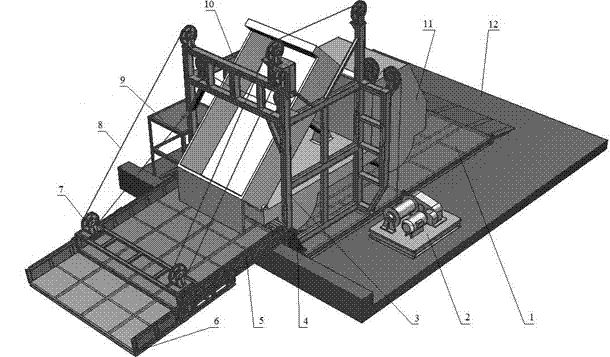

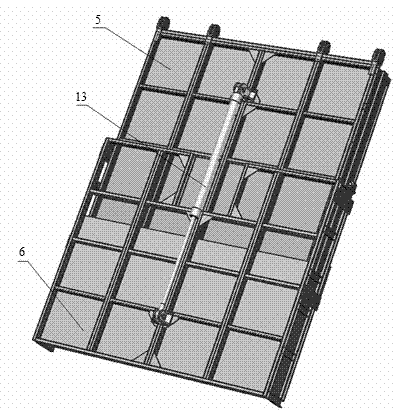

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] like figure 1 As shown, platform 1 is designed into flat and ramp structures according to the water level drop of the port. When the water level drop is small, the platform is designed as a flat structure. Weld the angle iron on the ordinary steel plate to prevent the cargo dump truck 11 from slipping when it starts; when the water level drop is large, it can be designed as a ramp structure. For the ramp structure, the angle value of the slope does not exceed 25°, and the supporting structure must Firm and reliable, the unloading position of the dump truck 11 is designed as a flat structure, which is convenient for the safe operation of the dump truck 11; in order to ensure the stability of the device and prevent rollover, the platform must be firmly and reliably connected to the bottom of the port 12.

[0022] When hoisting device 2 works, winding steel wire rope a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com