Dual-system material-smoothening automatic-balancing regulating control device and method

An automatic balancing and control device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of dual-system feeding material deviation difficulties, operator negligence, pressing materials, etc., to promote safe production and production capacity increase, normal operation guaranteed, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

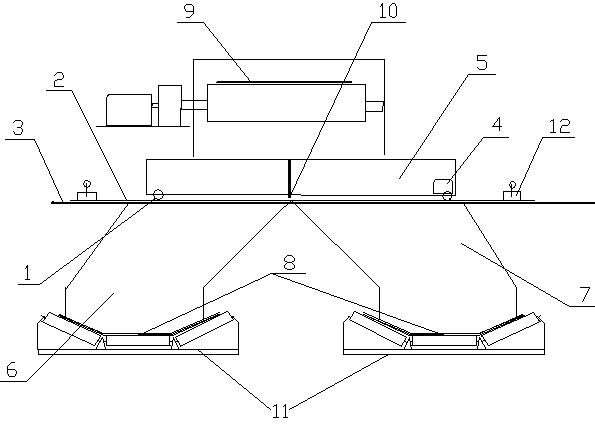

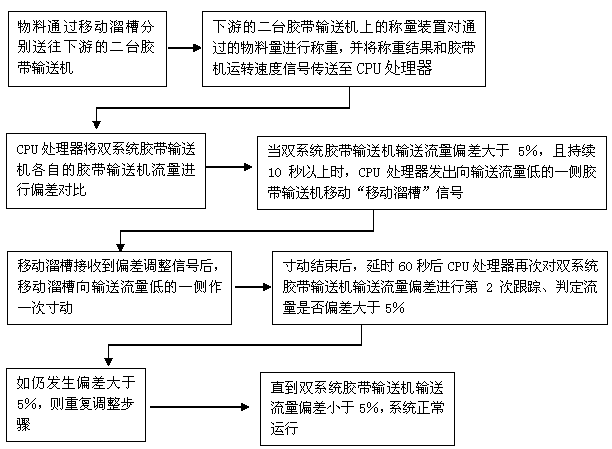

[0029] like figure 1 As shown, a dual-system feeding automatic balance adjustment control device includes a mobile trolley 1, a trolley track 2, a rail fixing frame 3, a trolley travel motor 4, a mobile chute 5, a dual-system left chute 6, a dual-system right chute 7 and Electronic scale 8, the trolley track 2 is fixed on the track fixing frame 3, limit stops 12 are arranged at both ends of the trolley track 2, the mobile trolley 1 is arranged on the trolley track 2, and the mobile chute 5 is installed on the mobile On the trolley 1, the mobile chute 5 is arranged below the upstream belt conveyor 9, and the feed port of the mobile chute 5 is matched with the upstream belt conveyor 9, and the double system left chute 6 and the double system right chute 7 are arranged on the mobile chute 5, the feed ports of the dual-system left chute 6 and the dual-system right chute 7 are matched with the discharge port of the mobile chute 5; The outlets of the chute 6 and the dual-system rig...

Embodiment 2

[0037] A dual-system feeding automatic balance adjustment control device, the difference between Embodiment 2 and Embodiment 1 is that in order to ensure that the distance of each displacement of the moving chute 5 is a fixed value, in the present invention, the trolley travel motor 4 It is a stepping motor, and the moving chute 5 is driven to move by the stepping motor, so that the single displacement distance adjustment of the moving chute 5 is more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com