Bulk cargo automatic ship-unloading system and method thereof

A multi-drive, main control unit technology, applied in loading/unloading, load hoisting components, transportation and packaging, etc., can solve problems such as being unsuitable for full automation of bulk cargo terminals, to improve operational efficiency, achieve full automation, and ensure The effect of safety features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

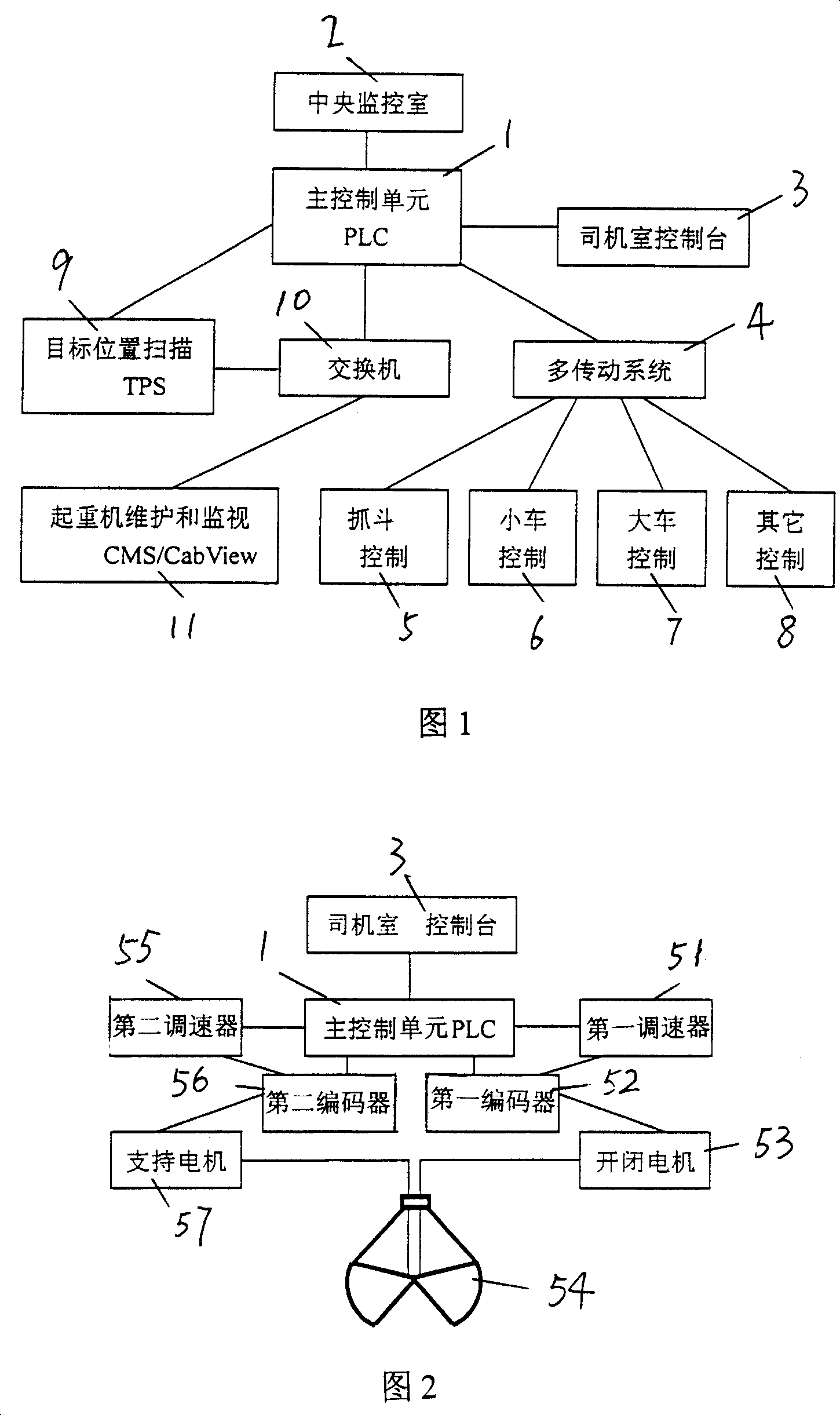

[0014] An automatic bulk cargo unloading system in Fig. 1, it includes a main control unit 1, the main control unit 1 is connected with the central monitoring room 2, the main control unit 1 is connected with the driver's cab console 3, the main control unit 1 is connected with the multi-drive The mechanism 4 is connected, the multi-transmission mechanism 4 is connected with the grab control unit 5, the multi-transmission unit 4 is connected with the trolley control unit 6, the multi-transmission unit 4 is connected with the cart control unit 7, and the multi-transmission unit 4 is connected with other control units 8, The main control unit 1 is connected to the target position scanning unit 9 , the main control unit 1 is connected to the switch 8 , the target position scanning unit 7 is connected to the switch 10 , and the switch 10 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com