Device and method for detecting heights of material piles at material throwing positions of dock wall moving type ship loader

A technology of height detection device and quay wall shifting machine, which is applied in the direction of measuring device, optical device, instrument, etc., can solve problems such as difficulty in ensuring accuracy, damage to bulkhead, damage to the ground of the storage yard, etc., and achieve high accuracy and stability Good, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

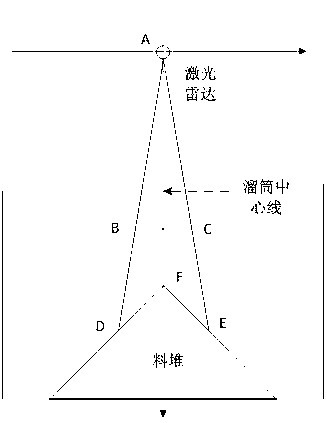

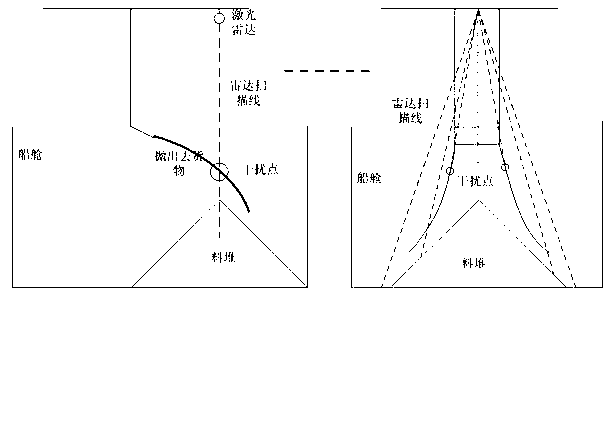

[0020] based on the following Figure 1 ~ Figure 3 , specifically explain the preferred embodiment of the present invention.

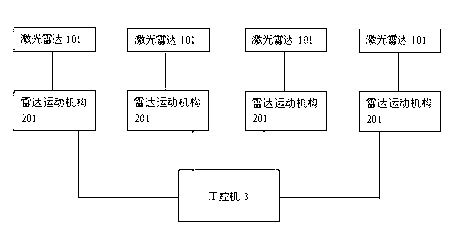

[0021] Such as figure 1 As shown, the present invention provides a device for detecting the dumping position and pile height of a quay-wall shifting ship loader, which includes a circuit-connected laser radar array, a radar movement mechanism and an industrial computer 3 .

[0022] The laser radar array includes four two-dimensional laser radars 101, which are respectively installed on the four corners of the square maintenance platform of the barrel of the ship loader.

[0023] The radar movement mechanism is a servo motor 201, and its servo motor driver can directly receive the communication command from the industrial computer to perform position control and drive the laser radar to scan at multiple angles in the horizontal direction.

[0024] The industrial computer 3 is used for background data processing, and has a display, which can monitor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com