Flow-type multi-purpose bulk cargo spiral stacking machine

A multi-purpose, mobile technology, applied in the field of loading equipment, bulk material pile height and ship loading, it can solve the problems of high energy consumption, low operating efficiency and low utilization rate of dump trucks, etc., and achieve the safety and stability of the whole vehicle High efficiency, improved operating efficiency, and strong adaptability to the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

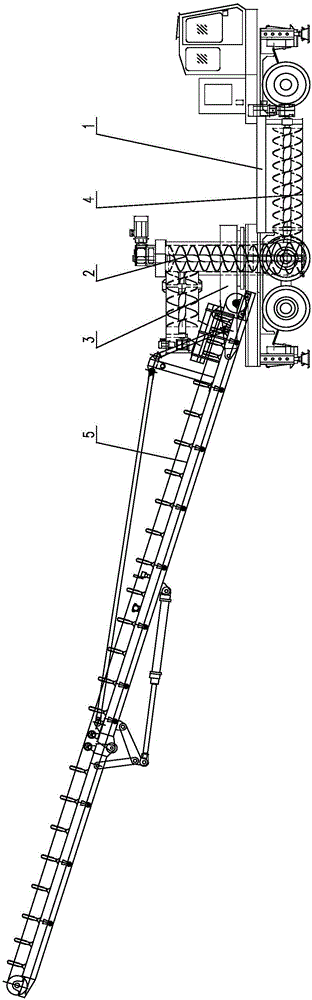

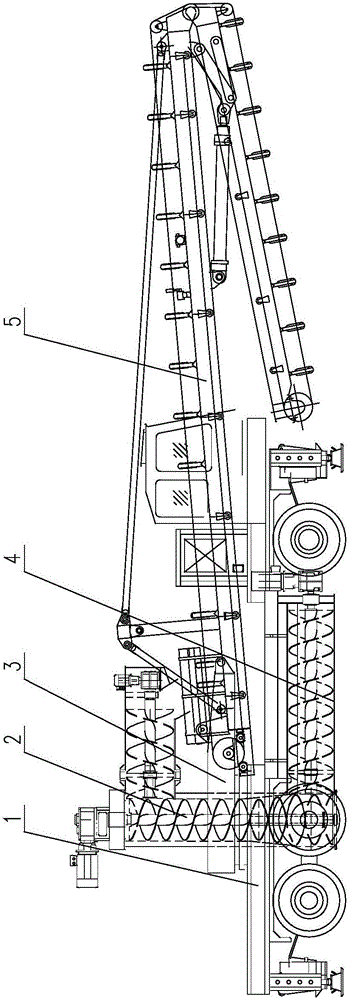

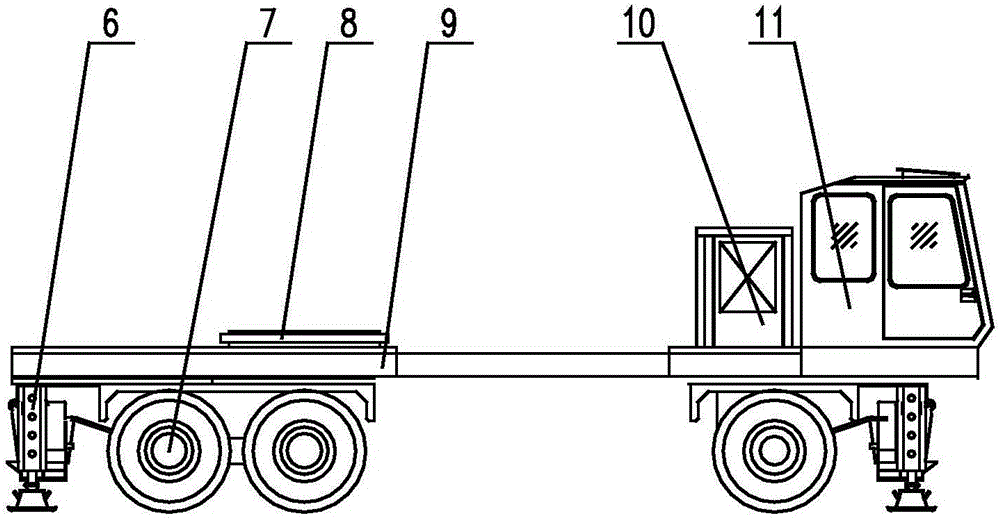

[0019] like figure 1 , figure 2 As shown, the mobile multi-purpose bulk cargo screw stacker includes a car body assembly 1, a screw transfer system 2, a rotary mechanism 3, a material receiving device 4 and a folding belt conveyor 5. The car body assembly 1 is placed on the ground, moves through the walking and steering mechanism 7 when walking, and is supported by the hydraulic support legs 6 when working. The material receiving device 4 is arranged at the middle part of the vehicle frame 9 of the vehicle body assembly 1, and is connected and fixed with the vehicle frame 9 by bolts, thereby receiving the unloading of the dump truck during work. The horizontal conveying screw 19 in the screw transfer system 2 is in the trough 22 of the material receiving device 4, and is fixedly connected to the trough 22 through the intermediate support 36 and the tail support 37, and the tail end is arranged on the outer side of the end wall of the trough 22. The horizontal conveying scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com