Marine bulk cargo transferring system ship

A technology for bulk carriers and hulls, applied in ship accessories, cargo handling equipment, ships, etc., can solve the problems of small coverage of loading operations, poor type of transfer equipment, low transfer capacity, etc., and achieve large loading coverage and high transfer capacity. , the effect of high unloading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

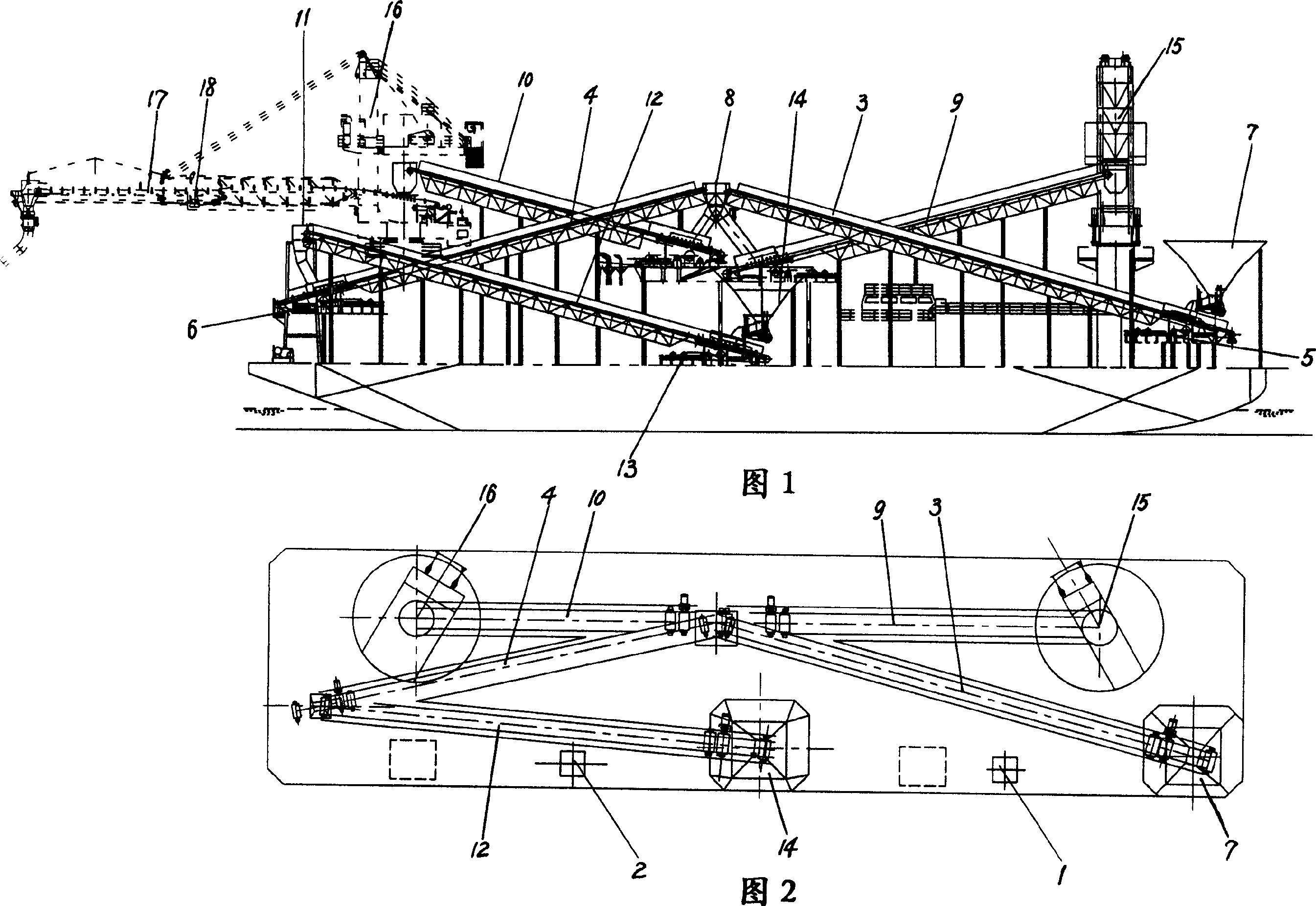

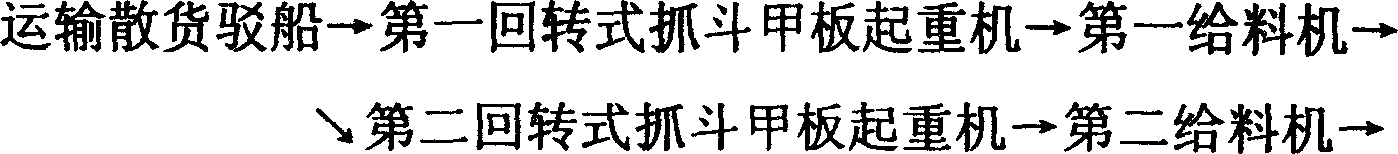

[0025] Referring to Fig. 1 and Fig. 2, the present invention is a kind of marine bulk cargo transshipment system ship, power equipment and hoisting equipment are housed on the hull. As a bulk cargo reloading system, it includes a rotary grab deck crane, a belt conveyor system, a retractable rotary ship loader, and a power supply control system.

[0026] As shown in Figure 2, the rotary grab deck crane is fixedly placed on the main deck of the hull. The slewing grab deck crane is composed of a first slewing grab deck crane 1 and a second slewing grab deck crane 2 which are arranged separately, and the two cranes are arranged at a certain distance apart on the main deck of the hull. The crane is composed of a column, a tower, a slewing, luffing, and lifting mechanism, and has functions such as slewing, luffing, grab lifting, opening and closing.

[0027] The belt conveyor system can be composed of more than five belt conveyors, and each belt conveyor is connected through the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com