Cargo container cradle

a cargo container and cradle technology, applied in the direction of transportation and packaging, dismountable cabinets, movable shelf cabinets, etc., can solve the problems of increasing the risk of injury associated with equipment that does not necessarily meet the strength and size requirements currently being adopted, and the proliferation of equipment previously manufactured and used that does not necessarily meet the requirements of strength and siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

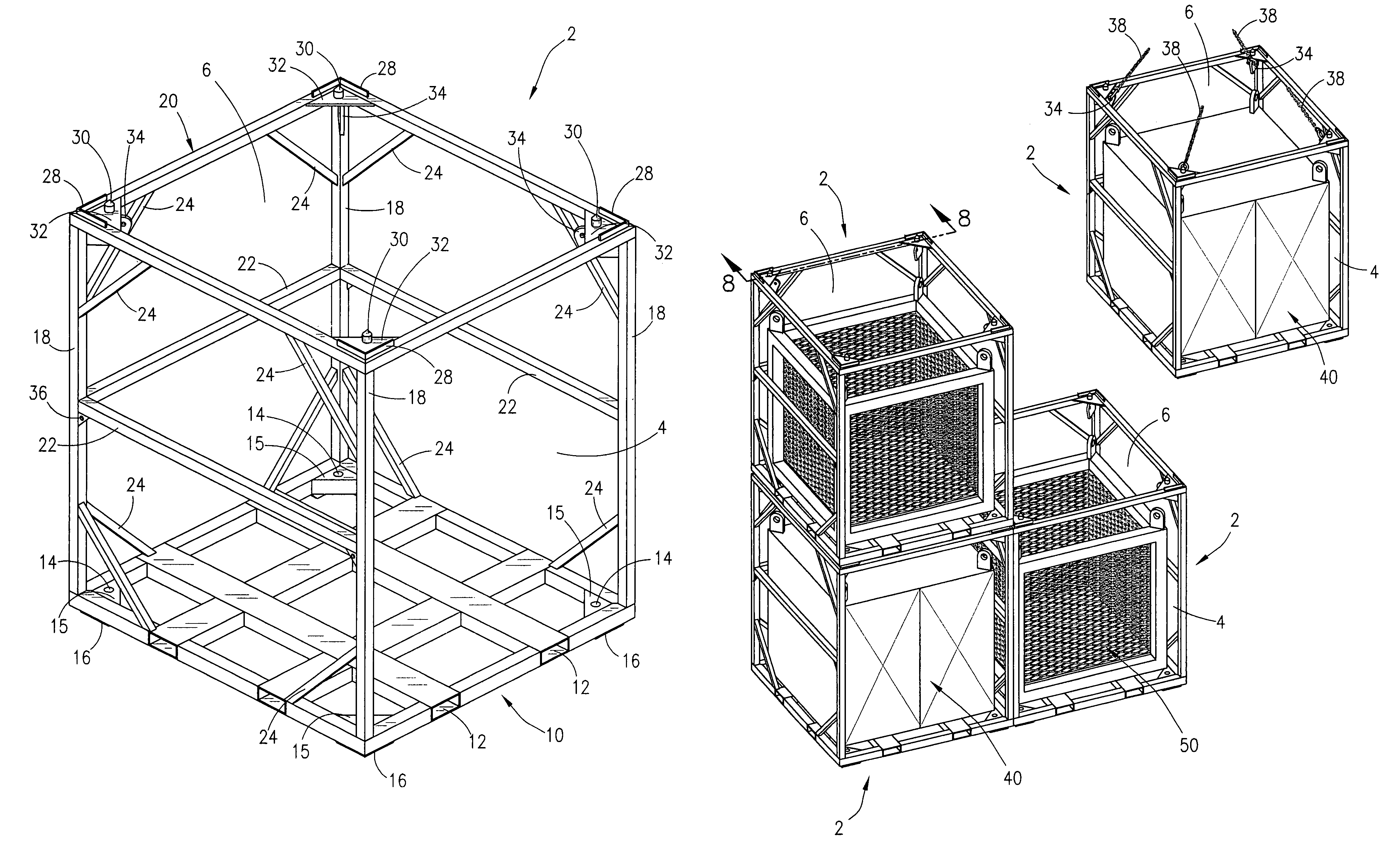

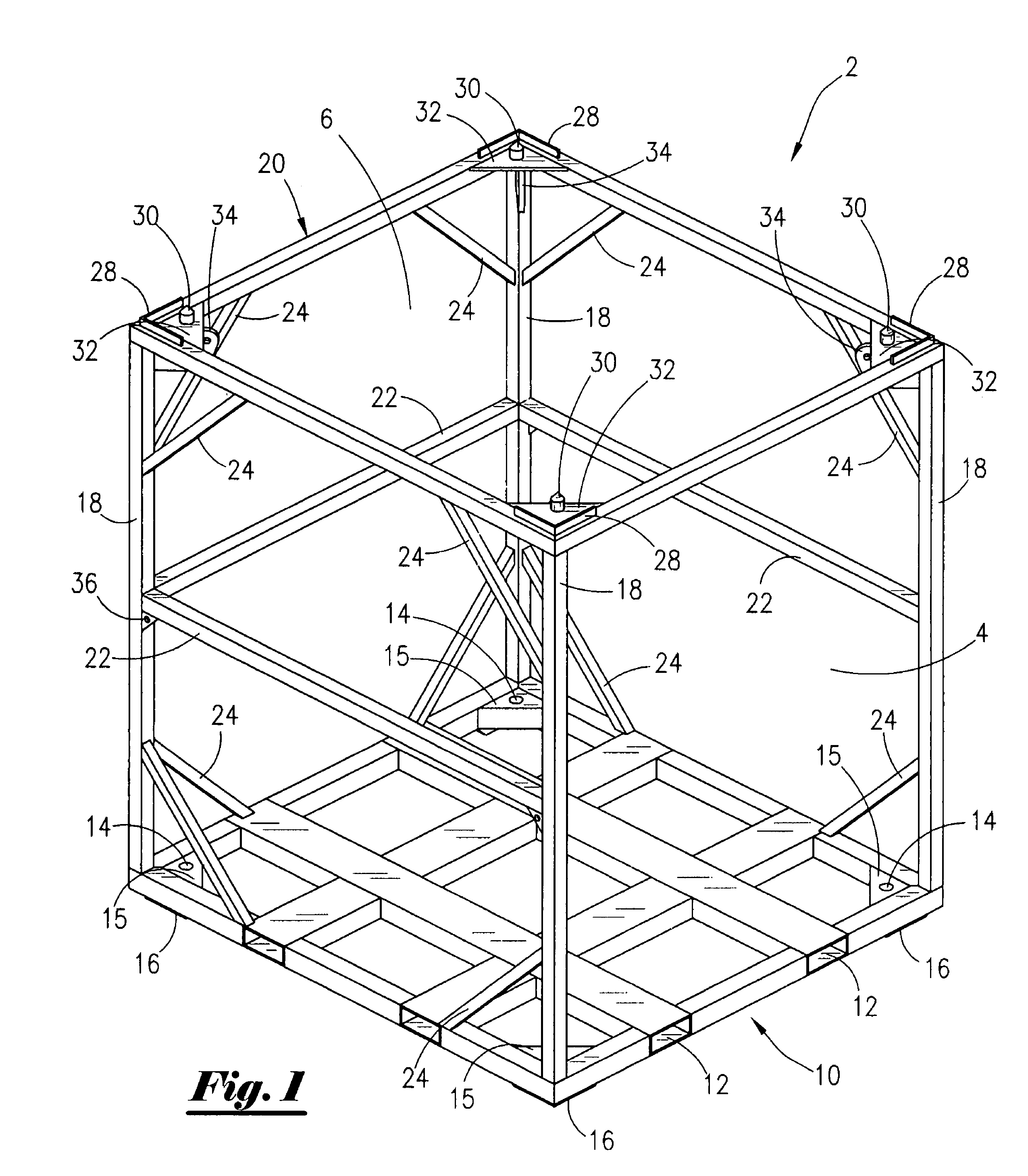

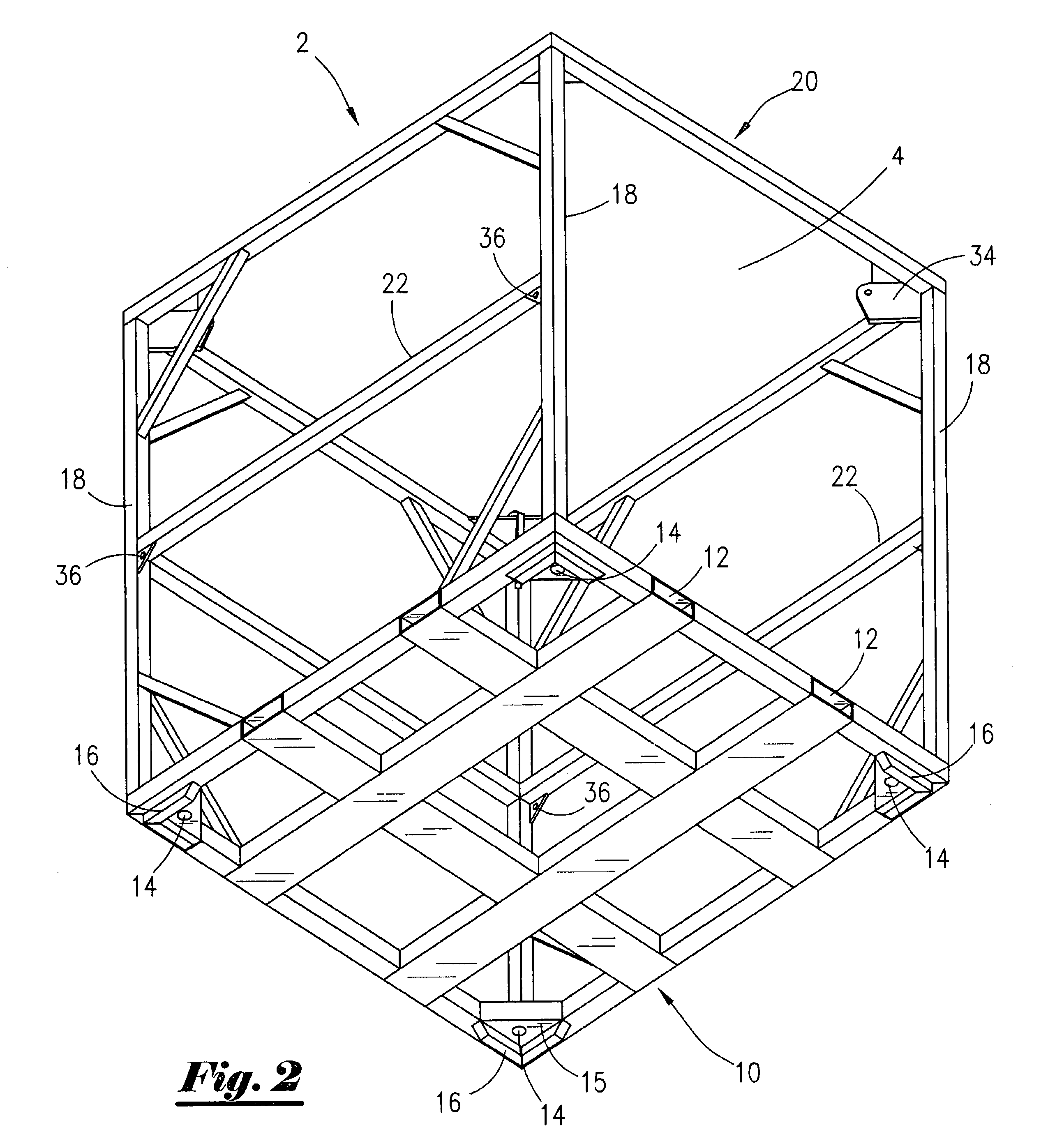

[0029]Referring to FIGS. 1 and 6, the cargo container cradle 2 is a single bay cradle unit intended to support at least one non-certified containers or baskets. It is comprised of a floor or base frame 10 made up of a network of beams and braces. The base frame 10 has openings 12 positioned to receive the tines of a forklift or pallet jack to facilitate the lifting of the cradle. Extending from each corner of the base frame 10 are base frame support bars 16. These base support bars 16 keep the cradle 2 off the deck or floor surface to avoid the accumulation of moisture around the cradle. Angled corner plates 15 extend from each corner of the base frame 10 inward toward the interior of the base frame 10. These corner plates 15 strengthen the base frame 10 and provide space for holes 14 to receive stacking pins 30 to facilitate stacking and interlocking of cradles 2 when the cradles 2 are stacked one upon another.

[0030]The base frame 10 has vertically extending support posts 18 upon w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com