Combinatorial synthesis

a technology of combinatorial synthesis and synthesis, applied in the field of combinatorial synthesis, to achieve the effect of lightly punched and ready-to-punch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

General

[0074] For the following examples, ceramic sheets obtained from Mistler (Morrisville, Pa.), were made from a cordierite powder mixed with a binder and tape-cast into a 6½″ voll with a thickness of 0.047″. These squares subsequently require a heating procedure to both remove the binder and provide rigidity to the piece. The cordierite sheets were placed onto a flat surface lightly dusted with powdered cordierite, and placed into a furnace with the following profile: room temperature to 932° F. over 1-6 hours, hold for ½ hour, ramp to 2100-2300° F. over 1-7 hours, hold for 0.5-12 hours, then cool slowly to room temperature. Longer heating times than those listed here are generally acceptable.

[0075] Examples of other tapes useful for this application are a 100% alumina tape and a 96% alumina / 4% glass (magnesium aluminum silicate). An alumina marketed under Alcoa A-16SG is useful. The alumina tapes have a similar thickness to the cordierite tapes. The 96% alumina tapes range in...

examples 1-16

[0078] A standard carrier used in the following experiments had the following formulation: [0079] 1.1 wt % N100 Ethyl Ether Cellulose (Hercules-Aqualon N100 grade) dissolved overnight in a 1:1 mixture of a-Terpineol (Aldrich) and Texanol (American Chemicals).

[0080] The following formulations are examples only. The possible variations are not limited to this list. Also prepared and used were other carriers with the following formulations. These variations were used to change the viscosity and solids loading of the final inks. [0081] (1) 1.1 wt % N50 Ethyl Ether Cellulose (Hercules-Aqualon N50 grade) dissolved in a 1:1 mixture of a-Terpineol (Aldrich) and Texanol (American Chemicals) [0082] (2) 1.1 wt % N300 Ethyl Ether Cellulose (Hercules-Aqualon N300 grade) dissolved in a 1:1 mixture of a-Terpineol (Aldrich) and Texanol (American Chemicals) [0083] (3) 0.55 wt % N100 Ethyl Ether Cellulose (Hercules-Aqualon N100 grade) dissolved in a 1:1 mixture of a-Terpineol (Aldrich) and Texanol (...

example 17

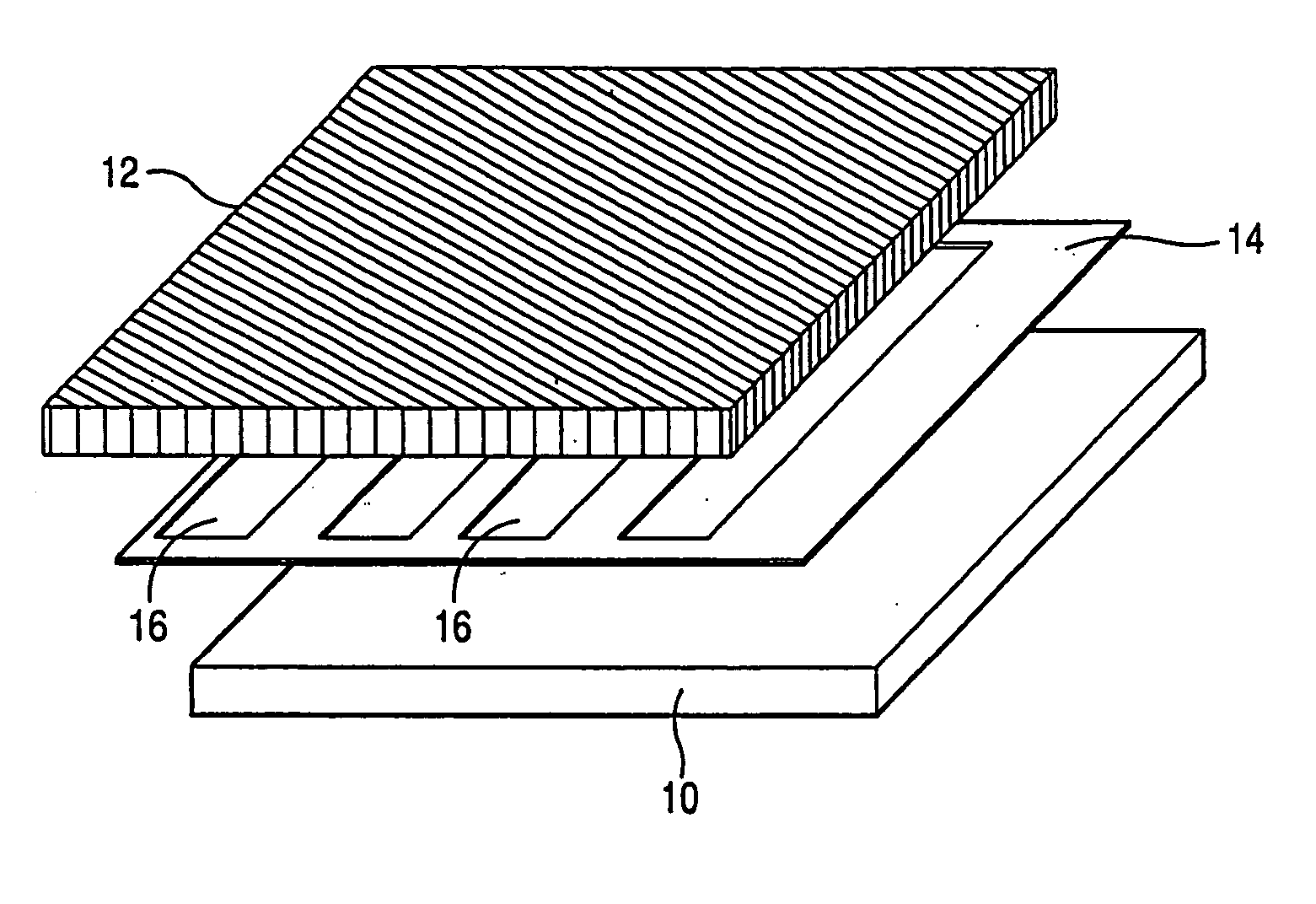

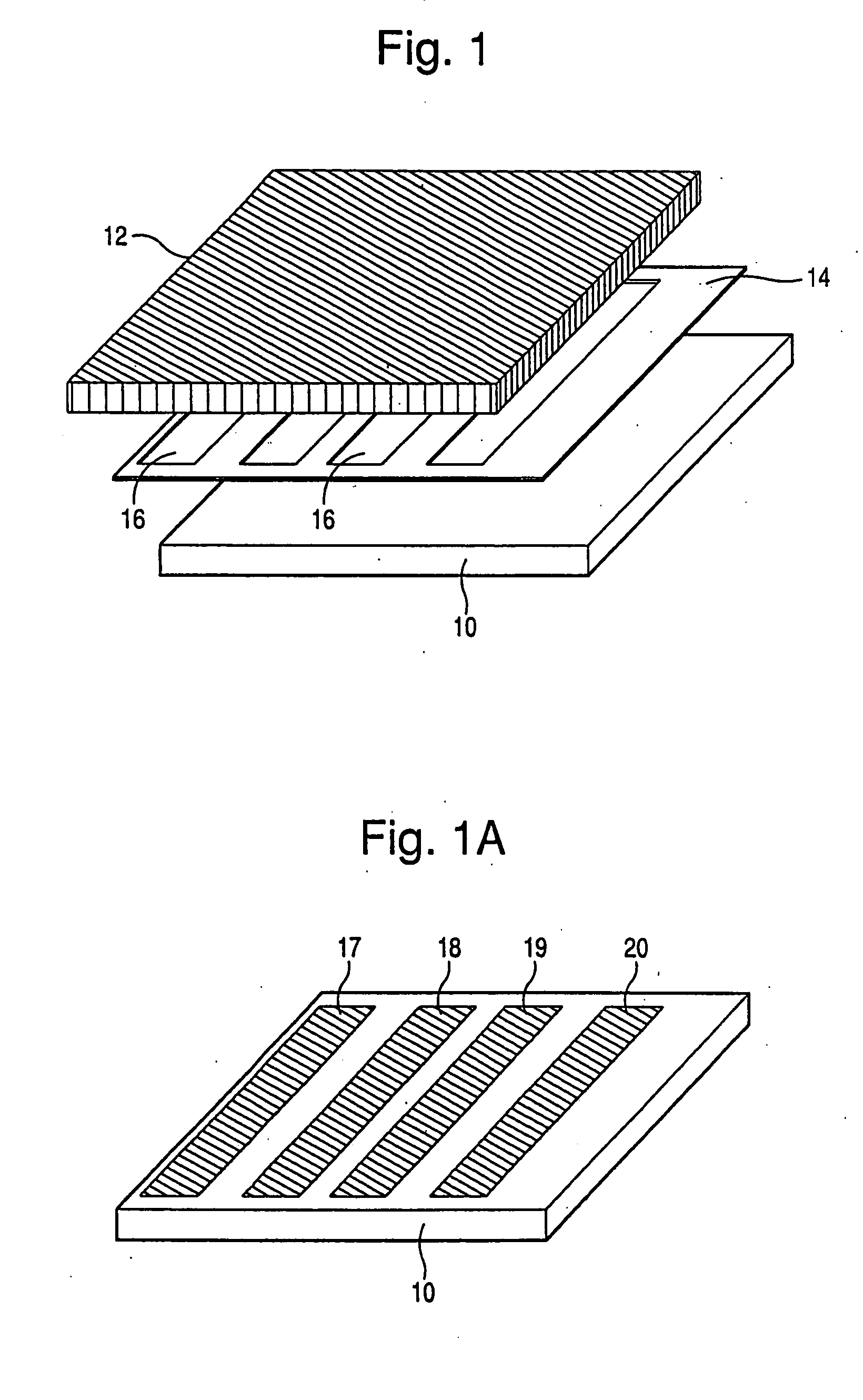

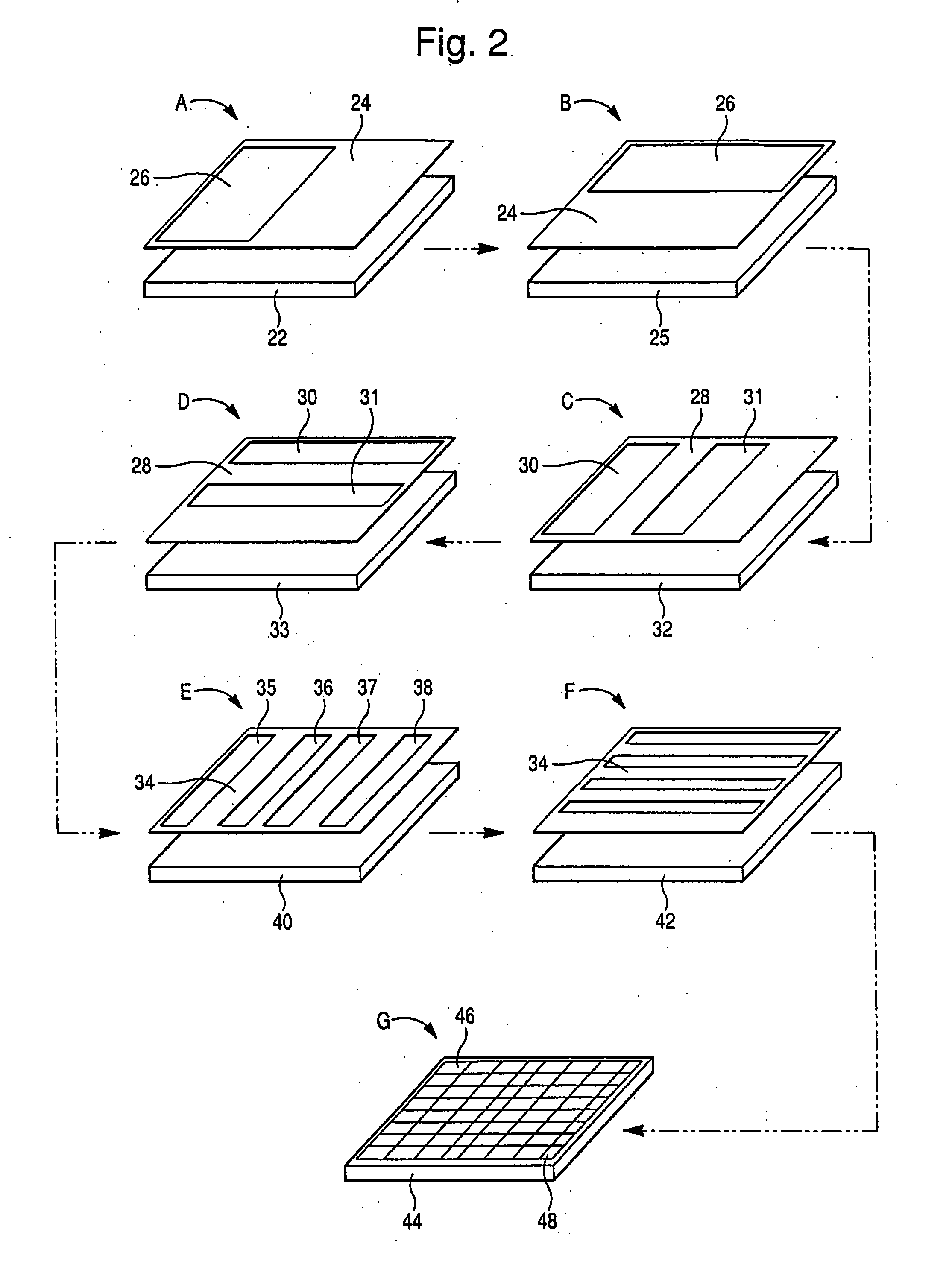

[0089] A spray gun was used to spray coat four different catalyst slurries onto the cordierite sheet. The following four slurries and the corresponding masks (referring to FIG. 2) were used: Zeolite Y (mask A), Cu-ZSM-5 (mask B), Pt—Al2O3 (mask C), and CeO2 (mask D).

[0090] After the spray coatings were completed, there were sixteen individual and unique areas of the cordierite sheet with different coatings. The coated sheet was calcinated to 1000° F. for 2 hours to remove any moisture and organic components.

[0091] Circular sections were drilled out of the sheet in the various unique areas. The drill bit used was a diamond-tipped coring bit with an I.D. of 3.89 mm. The coatings held up very well under the drilling process, and minimal flaking and damage was observed under an optical microscope. The diameter of the circular sections ranged between 3.5 and 3.6 mm.

[0092] The goal was to deposit approximately 0.0075 g / in2 of each of the four slurries. The resulting coatings for the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com