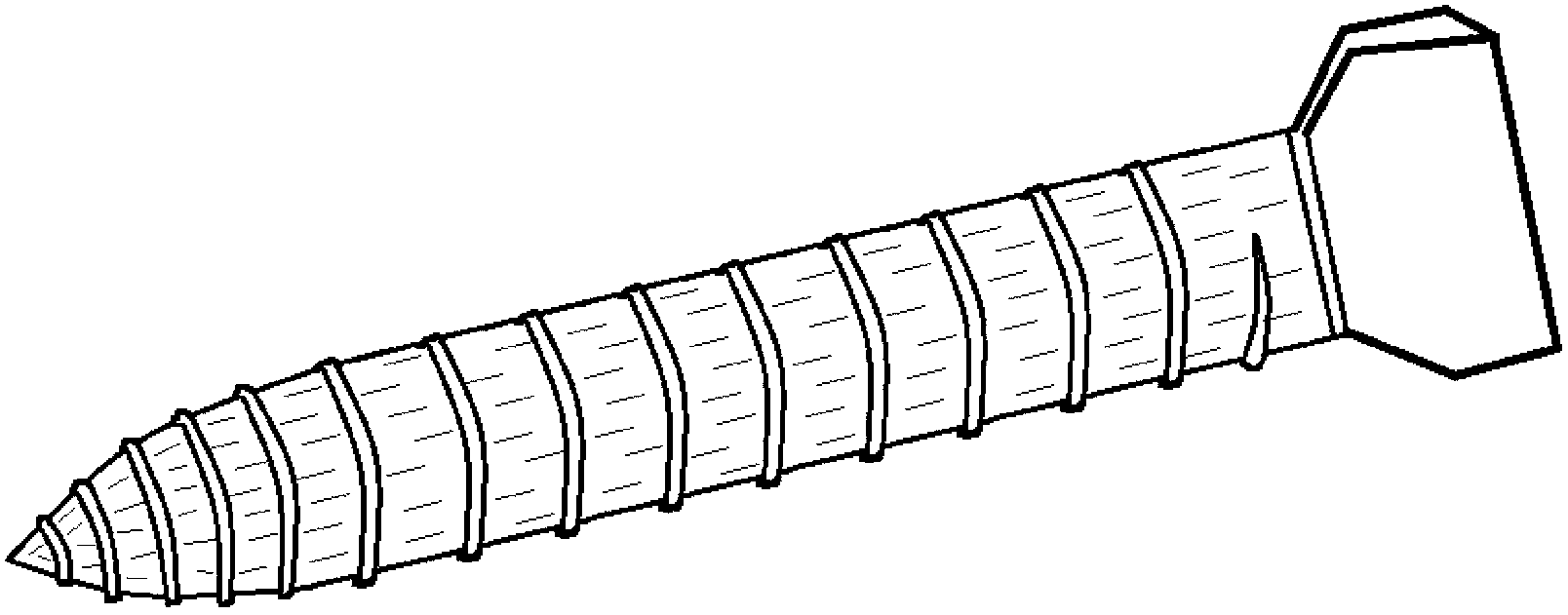

PLA absorbable bone screw with PBC as toughening agent, and preparation method thereof

A technology of toughening agent and bone nail, which is applied in the application field of biomedical materials, can solve the problems of high brittleness, poor toughness, PLA is not suitable for degradable bone nails, etc., and achieves low manufacturing cost, short process and good preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take a certain amount of PBC, PLA, and HAP, and dry them at a certain temperature and time to remove moisture. Among them, the weight ratio of PLA is 95%, the drying temperature is 100°C, and the drying time is 8 hours; the weight ratio of PBC is 4.5%, the drying temperature is 50°C, and the drying time is 8 hours; the weight ratio of HAP is 0.5%, and the drying temperature is 8 hours. 120°C, drying time 8 hours.

[0024] (2) Blend the dried PBC, PLA, and HAP in a twin-screw blender at a temperature of 190°C, and then inject them into a mold to form a cylindrical PBC / PLA / HAP with a diameter of 1.8mm Compound splines.

[0025] (3) Place the composite spline in a material stretching machine for stretching, the temperature of the heating air is 120°C, and the stretching ratio is 2.5 times.

[0026] (4) Cut the stretched spline to make a screw with a diameter of 1 mm to obtain the desired degradable bone nail.

Embodiment 2

[0028] (1) Take a certain amount of PBC, PLA, and HAP, and dry them at a certain temperature and time to remove moisture. The weight ratio of PLA is 90%, the drying temperature is 100°C, and the drying time is 8 hours; the weight ratio of PBC is 9%, the drying temperature is 50°C, and the drying time is 8 hours; the weight ratio of HAP is 1%, and the drying temperature is 8 hours. 120°C, drying time 8 hours.

[0029] (2) Blend the dried PBC, PLA, and HAP in a twin-screw blender at a temperature of 180°C, and then inject them into a mold to form a cylindrical PBC / PLA / HAP with a diameter of 2.8mm Compound splines.

[0030] (3) Place the composite spline in a material stretching machine for stretching, the temperature of the heating air is 100°C, and the stretching ratio is 5 times.

[0031] (4) Cut the stretched spline to make a screw with a diameter of 1.2 mm to obtain the desired degradable bone nail.

Embodiment 3

[0033] (1) Take a certain amount of PBC, PLA, and HAP, and dry them at a certain temperature and time to remove moisture. The weight ratio of PLA is 85%, the drying temperature is 100°C, and the drying time is 8 hours; the weight ratio of PBC is 12%, the drying temperature is 50°C, and the drying time is 8 hours; the weight ratio of HAP is 3%, and the drying temperature is 8 hours. 120°C, drying time 8 hours.

[0034] (2) Blend the dried PBC, PLA, and HAP in a twin-screw blender at a temperature of 170°C, and then inject them into a mold to form a cylindrical PBC / PLA / HAP compound with a diameter of 12mm. module.

[0035] (3) Place the composite spline in a material stretching machine for stretching, the temperature of the heating air is 60°C, and the stretching ratio is 3.5 times.

[0036] (4) Cut the stretched spline to make a screw with a diameter of 6 mm to obtain the desired degradable bone nail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com