Sludge high-pressure three-phase separation method

A three-phase separation, high-pressure technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of inappropriate sludge treatment, slightly poor effect, low separation efficiency, etc., and achieve remarkable results. Social and economic benefits, no secondary pollution, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

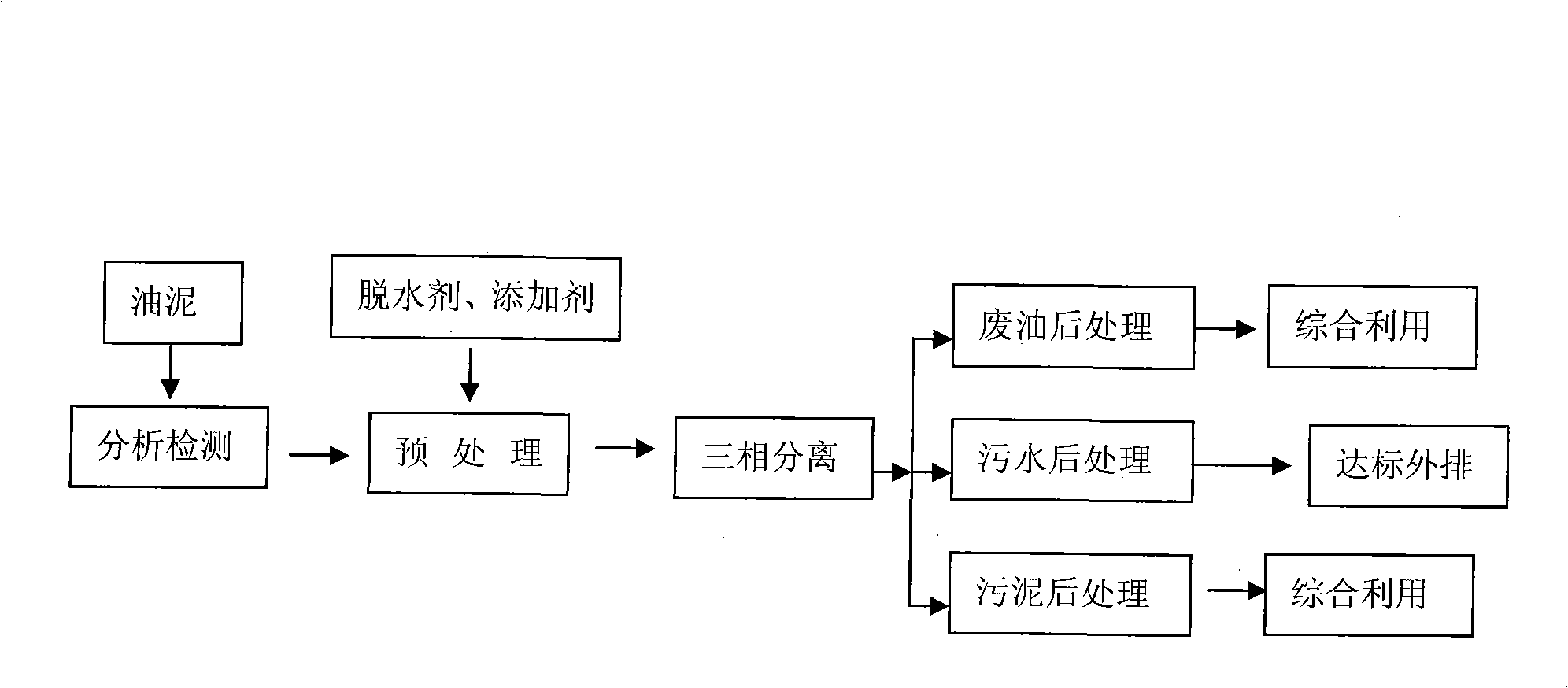

[0035] Use oil refinery scum as raw material to carry out oil sludge high-pressure three-phase separation treatment according to the following method, specifically as follows figure 1 Shown:

[0036] The first step of pretreatment: test and analyze the mixed sample of oil sludge to be treated, the test method is as follows, moisture content: national standard water-oil mixed system water content determination method --- "Moisture determination method of petroleum products" GB / T260 ; Sulfur content: "Determination of Sulfur Content in Petroleum Products (Oxygen Bomb Method)" GB / T388; Calorific value: "Determination of Calorific Value of Petroleum Products" GB / T384-1981 (1988). According to the above sludge detection results, add dehydrating agent, cationic demulsifier and additives to 1 ton of sludge to be separated, and mechanically stir until uniform;

[0037] The second step of high-pressure three-phase separation: the above-mentioned pretreated oil sludge is subjected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com