Detection method for interface bonding strength of aluminum-steel composite material

A technology of interfacial bonding strength and composite materials, which is applied in the detection of interfacial bonding strength of metal composite materials and the field of detection of interfacial bonding strength of aluminum-steel composite materials. Solve problems such as the interface bonding strength of aluminum-steel composite materials, and achieve the effect of simple and convenient preparation of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for detecting the interfacial bonding strength of aluminum-steel composite materials of the present invention comprises the following steps:

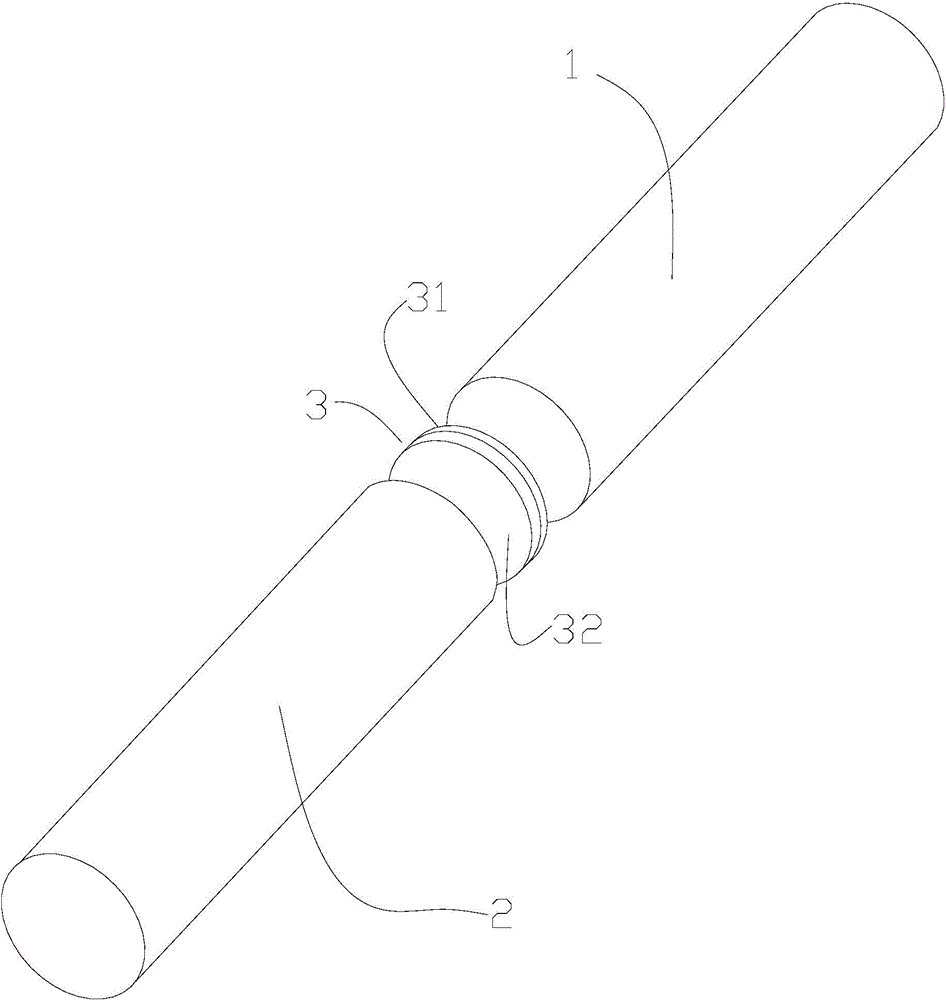

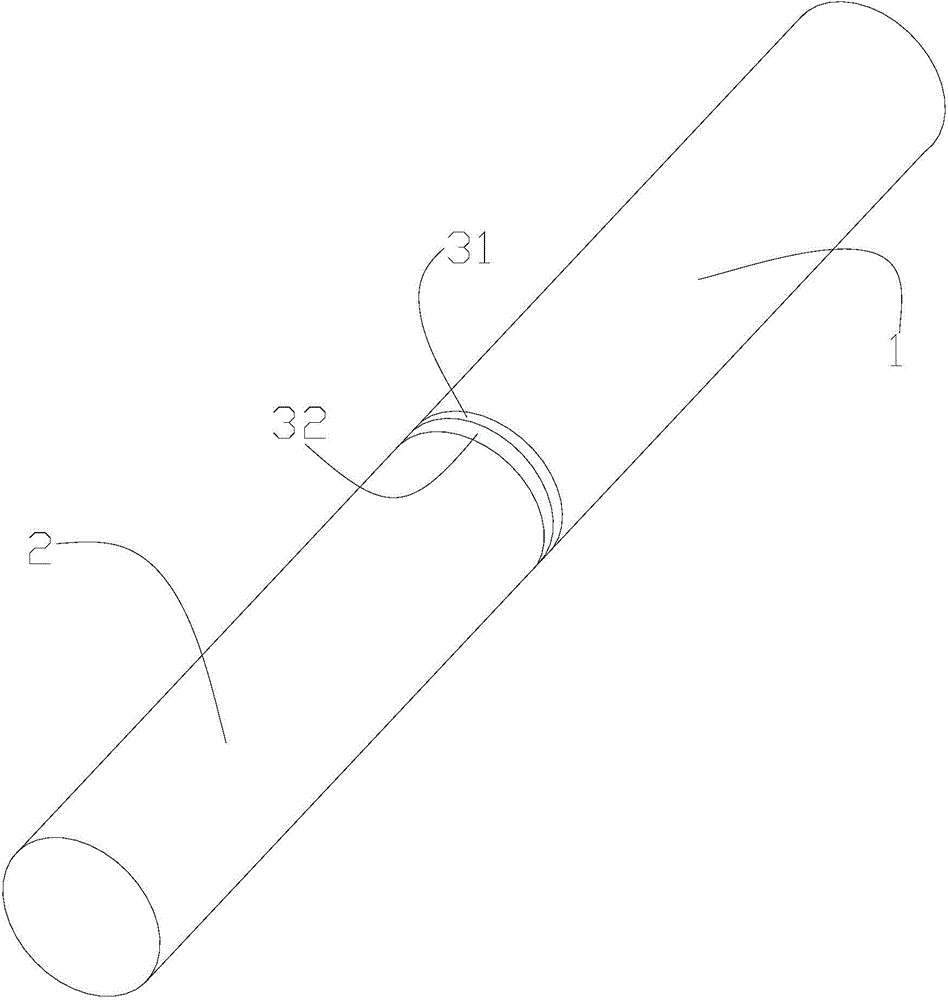

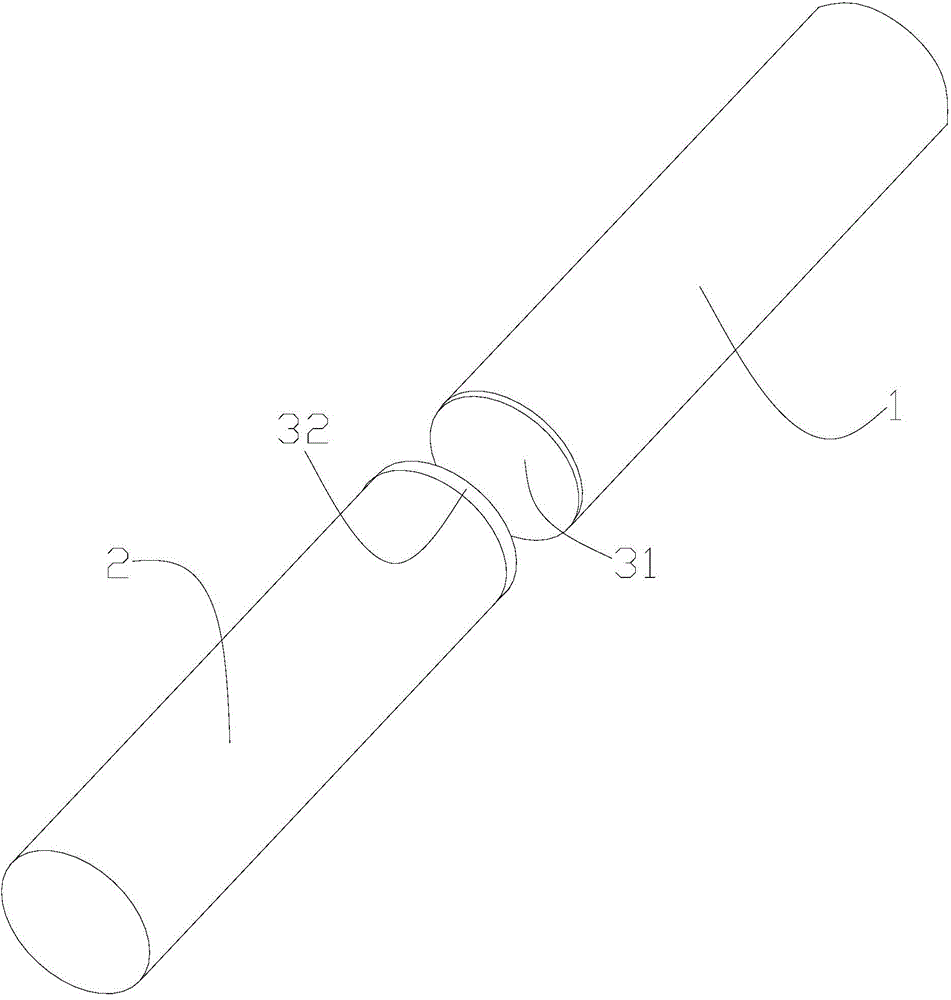

[0027] A. Prepare the wafer sample 3 and metal rods 1 and 2, cut the wafer sample 3 on the aluminum-steel composite material, make or select two metal rods 1 and 2 with the same cross-sectional diameter as the wafer sample 3, and the metal rod The lengths of 1 and 2 are at least greater than 50 mm. Wherein, the total thickness of the wafer sample 3 is 1.5 mm, and the thickness of the aluminum plate 31 is less than 0.15 mm. Preferably, the diameter of the wafer sample 3 and the cross-sectional diameter of the metal rods 1 and 2 are 20 mm, the length of the metal rods 1 and 2 is 80 mm, and the metal rods 1 and 2 generally use aluminum rods;

[0028] B. Clean the surface of the disc sample 3 and the metal rods 1 and 2 to be pasted, to clean off the oil stain and the oxide layer on the surface to be pasted, the circular pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com