Preparation method of aluminum steel composite grain structure, sample, reagent and preparation method

A composite material and grain technology, which is applied in the preparation of test samples and other directions, can solve the problems of difficult to observe the grain arrangement of the aluminum-steel composite interface, violent reaction, serious surface oxidation, etc., and achieve convenient and efficient observation and measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

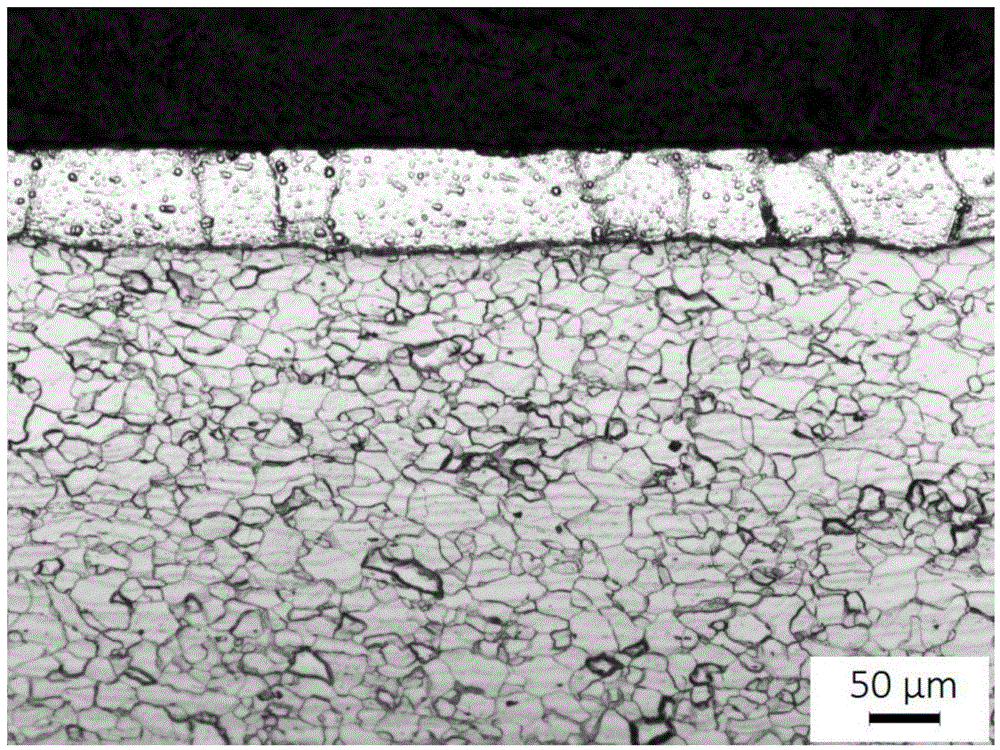

[0042] This embodiment takes the annealed aluminum (1XXX series)-steel (carbon structural steel) composite material for the base pipe of the air-cooling system of a thermal power station as an example to illustrate the technical solution of the present invention.

[0043] Prepare aluminum-steel composite specimens. The sample can be prepared by itself, and the preparation method is as follows:

[0044]The 4A60 / 08Al aluminum-steel composite plate used for the base pipe of the air-cooling system of the thermal power station is cut into a composite material sample with a length and width of 30mm, and then the composite material sample is passed through 320#, 600#, and 1200# water-resistant sandpaper in order from coarse to Finely ground and mechanically polished, cleaned with alcohol and dried such as blow-drying before use. When grinding, the surface of the sample needs to be rinsed with cooling water continuously, especially when grinding with 1200# sandpaper, before the basic...

no. 2 example

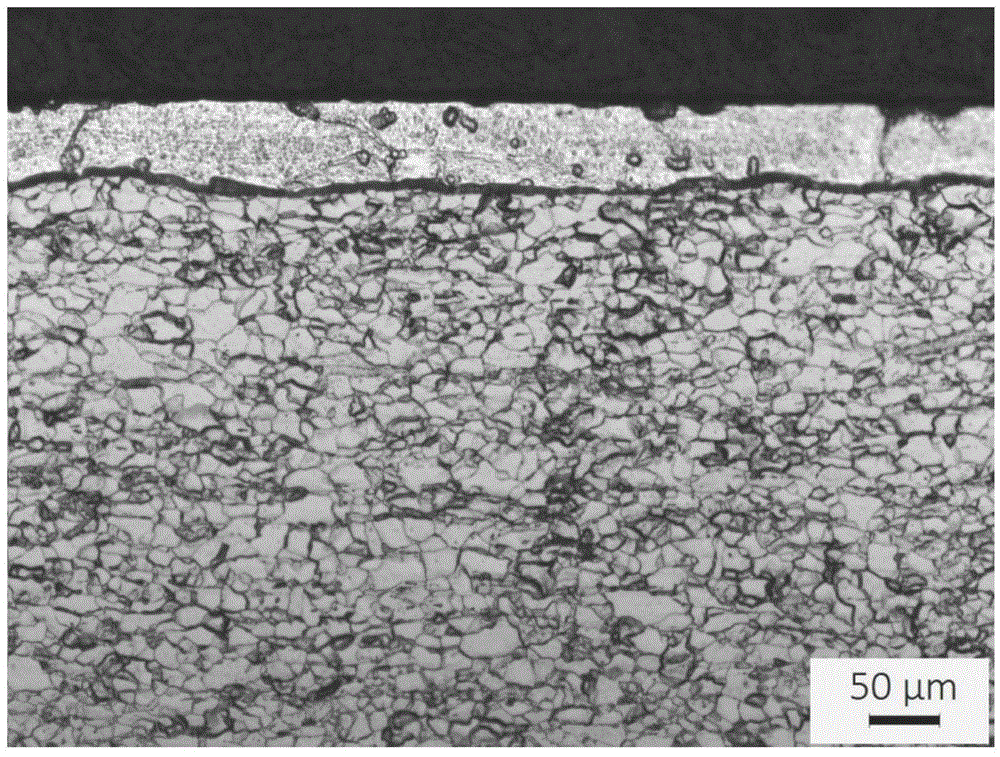

[0071] According to the method in the first embodiment of the present invention, the second embodiment also carried out the same test on the Al-0.8Si-0.08Zr / 08Al aluminum-steel composite material to prepare the grain structure, and the prepared aluminum-steel composite material The enlarged view of the grain structure is shown in figure 2 shown.

[0072] from figure 2 It can be seen that the metallographic structure is divided into two parts by a clear boundary, one side is the grain structure of the aluminum side of the aluminum-steel composite material sample, and the other side is the grain structure of the steel side of the aluminum-steel composite material.

no. 3 example

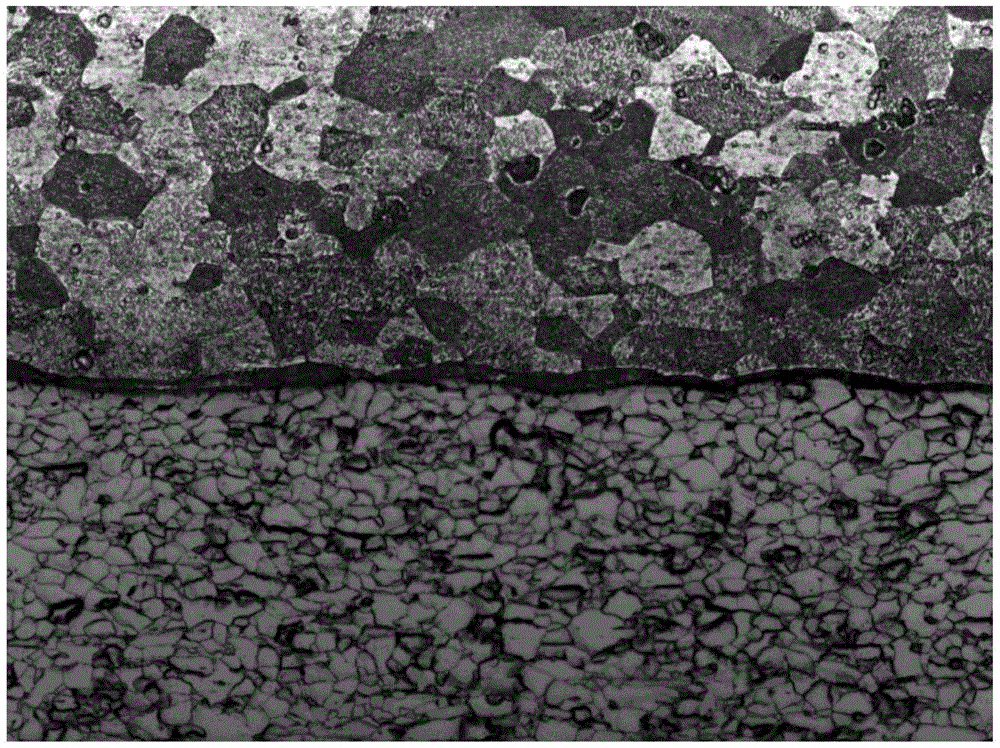

[0074] In the step of preparing the grain structure, if step S20 is missing, that is, the composite material sample after electrolysis is not cleaned with sodium hydroxide solution, and the sample is directly wiped with nital in step S3, the aluminum side is easy to blacken, and the grain boundaries are not clear.

[0075] In the third embodiment of the present invention, the magnified view of the grain structure prepared by step S3 directly after the electrolysis of the 1060 / 08Al aluminum-steel composite material is as follows: image 3 shown.

[0076] from image 3 It can be seen that the aluminum side and the steel side of the metallographic structure obtained at the same time are not easy to identify, and the boundary is not obvious.

[0077] And after adopting step S20 after electrolysis and adopting step S3 again, the grain structure enlarged picture of the sample preparation of same material is as follows Figure 4 shown.

[0078] from Figure 4 It can be seen that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com