Method for modifying aramid fiber composite by subzero treatment

A fiber composite material, cryogenic treatment technology, applied in the field of high-performance fiber composite material modification, to achieve the effect of improving bending performance, convenient operation, and good bonding interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

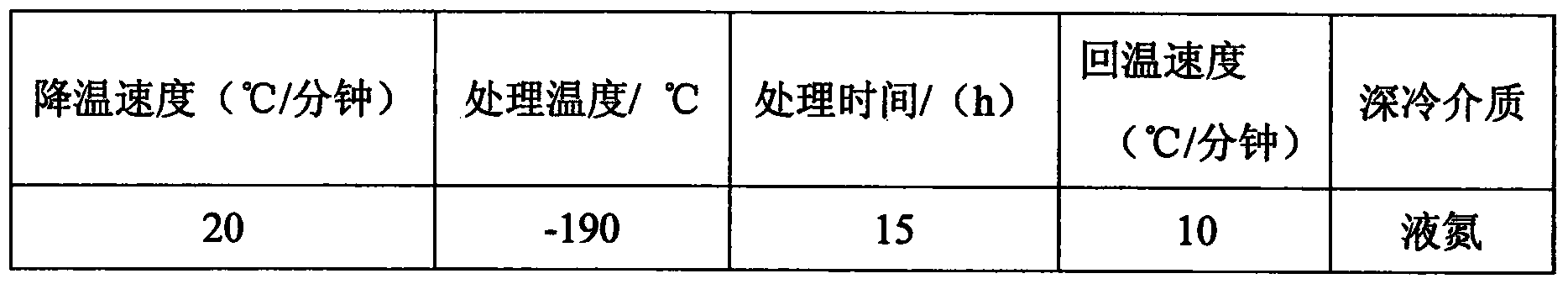

Embodiment 1

[0029] A method for modifying an aramid fiber composite material by cryogenic treatment, the aramid fiber composite material is an aramid fiber (Kevlar-29) non-woven fabric reinforced epoxy composite material, which includes a matrix resin and a matrix resin The volume ratio of aramid fiber used as reinforcement, matrix resin and aramid fiber is 50:50. The matrix resin is epoxy resin, and the aramid fiber is Kevlar-29, which is arranged in the matrix resin in the form of aramid nonwoven fabric. The aramid composite material is self-prepared, aramid parameters: fiber length 3 cm-6 cm, fiber monofilament diameter 12 microns; fabric structure: needle-punched non-woven felt; epoxy resin grade: JL-235. The preparation method is as follows: a vacuum-assisted resin transfer molding method is adopted. Specific steps: Put 4 layers of aramid fabric into the mold. During the vacuum-assisted molding process, the conduit on one side of the vacuum mold is inserted into the epoxy resin with...

Embodiment 2

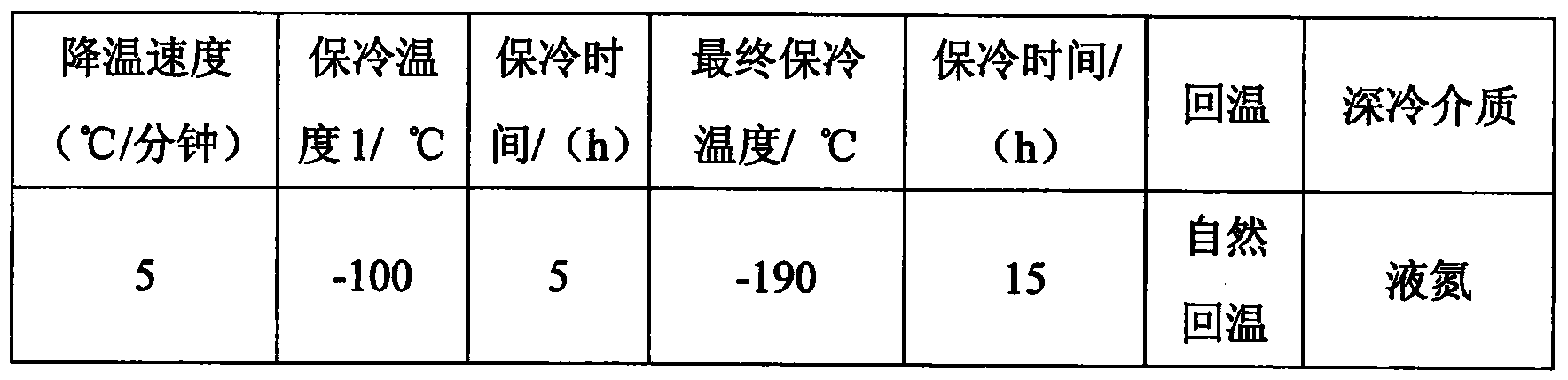

[0035] A method for modifying an aramid fiber composite material by cryogenic treatment, wherein the aramid fiber composite material is a two-dimensional aramid fiber (Kevlar-129) woven epoxy composite material, which includes a matrix resin and is located in the matrix resin The volume ratio of aramid fiber used as reinforcement, matrix resin and aramid fiber is 55:45. The matrix resin is epoxy resin, and the aramid fiber is Kevlar-129, which is set in the matrix resin in the form of aramid two-dimensional fabric. The aramid composite material is self-prepared. Aramid fabric parameters: K-129 fibers with warp and weft thickness of 1000D, warp and weft density of 5 threads / cm, fabric structure: two-dimensional plain weave fabric; epoxy resin grade: JL- 235. The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are the same as in Example 1. Composite material sample size is: length 30 cm, width 25 cm, thickness 4 mm.

[0036]...

Embodiment 3

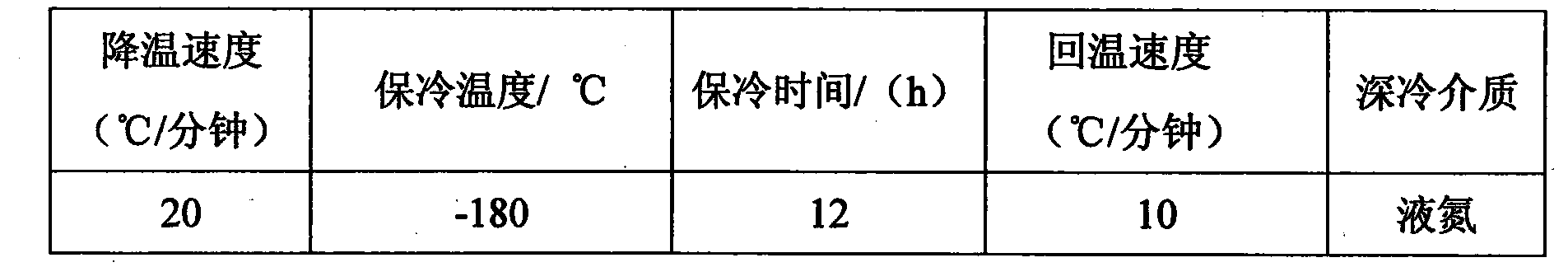

[0041] A method for modifying an aramid fiber composite material by cryogenic treatment, the aramid fiber composite material is a two-dimensional aramid fiber (Technora) woven unsaturated polyester composite material, which includes a matrix resin and a matrix resin The volume ratio of aramid fiber used as reinforcement, matrix resin and aramid fiber is 55:45. The matrix resin is unsaturated polyester, and the aramid fiber is Technora, which is set in the matrix resin in the form of aramid two-dimensional fabric. The aramid composite material is self-prepared. Aramid fabric parameters: Technora fibers with warp and weft thickness of 1500D, warp and weft density of 5 threads / cm, fabric structure: two-dimensional plain weave fabric; unsaturated polyester resin grade: 901VP. The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are the same as in Example 1. Composite material sample size is: length 30 cm, width 25 cm, thickness 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com