Method for measuring elastic modulus of coating

An elastic modulus and coating technology, applied in the field of measuring the elastic modulus of coatings, can solve problems such as the inability to use measurement, and achieve the effects of convenient and quick test efficiency, simple and easy process, and high test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

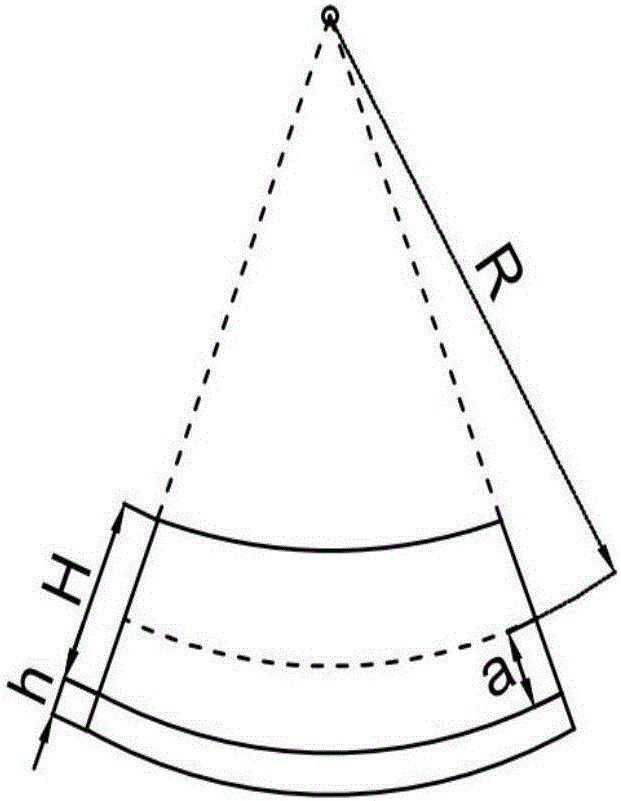

Image

Examples

Embodiment 1

[0046] Embodiment 1: the measurement of single-layer metal coating elastic modulus

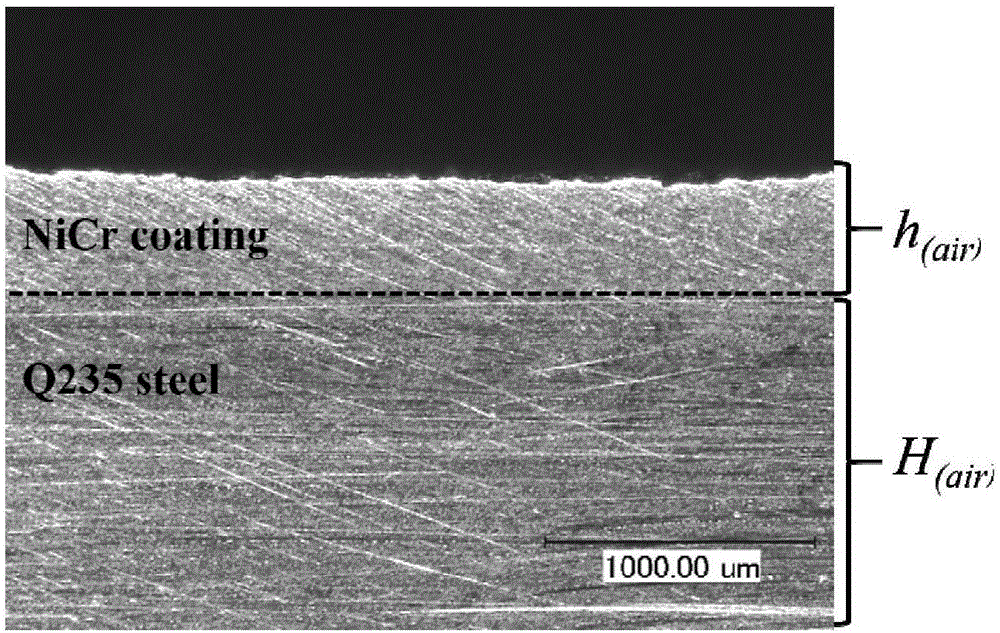

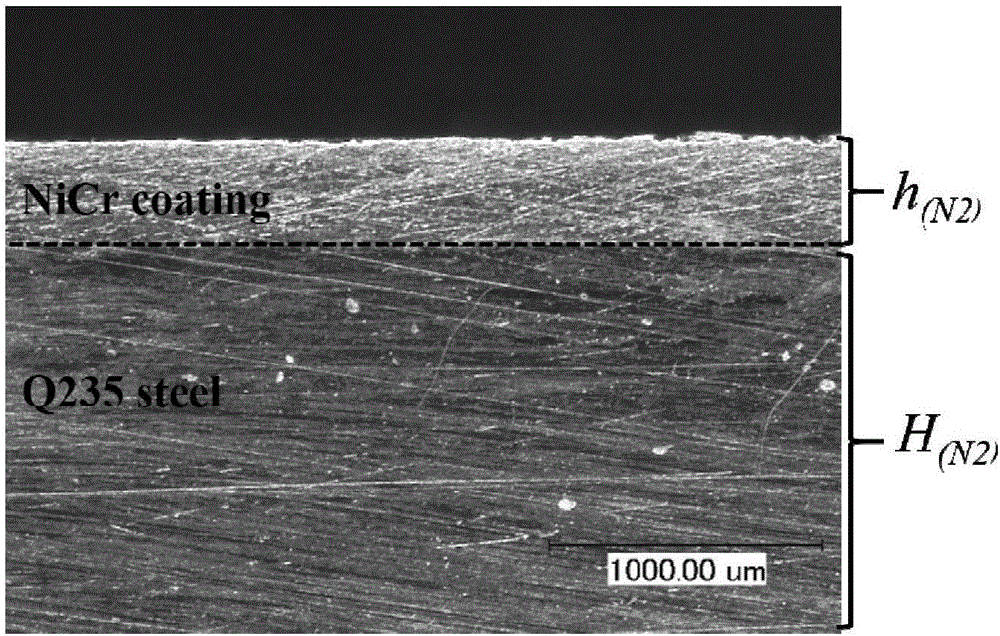

[0047] The coating sample to be tested is a NiCr coating prepared by supersonic flame spraying on the Q235 low-carbon steel substrate. The oxidizing gas is air and nitrogen respectively, and the spraying distance is 200mm. Before the preparation of the coating, the substrate materials are degreased and derusted, and the surface of the substrate is sandblasted with a particle size of 60 mesh brown corundum, an air pressure of 0.4-0.6MPa, a blasting angle of 45°, and a blasting distance of 160mm-180mm. After sandblasting, use acetone ultrasonic cleaning to remove impurities such as residual sand particles on the surface to ensure the bonding strength between the coating and the substrate. The cross-sectional morphology of the single-layer coating sample is shown in Figure 2, where 2a is the NiCr alloy coating obtained by atomizing gas as air; 2b is the NiCr alloy coating obtained by atomizing g...

Embodiment 2

[0059] Embodiment 2: the measurement of elastic modulus of multi-layer coating

[0060] For the measurement of the elastic modulus of multi-layer coatings, take the coating sample (coating 1+coating 2+substrate) of the two-layer coating as an example, first of all, it is regarded as the surface coating (that is, the outermost The test coating sample of the single-layer coating composed of coating, coating 1) and the remaining part (substrate+coating 2), is measured according to the steps of the test coating sample of the single-layer coating, and can be measured Elastic modulus E of surface coating (coating 1) q1 ; After the surface coating (coating 1) is removed, the remaining part (coating 2+substrate) is measured as a new coating sample to be tested, and the elastic modulus E of coating 2 can be measured q2 . According to this idea, the measurement of the elastic modulus of more layers of coatings can be realized.

[0061] The sample selected in the experiment is a comme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com