Ag2Nb4O11 nano-textured sheet particle and preparation method thereof

An ag2nb4o11 and flake particle technology is applied in the field of Ag2Nb4O11 nano-textured flake particles and their preparation, which can solve the problems of high requirements for preparation conditions, difficult control of particle morphology and microstructure, and complicated steps, and achieves simple and repeatable operation. High performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of Ag disclosed by the present invention 2 Nb 4 o 11 A preparation method for nano-textured sheet-like particles, comprising the following steps:

[0027] Step 1, according to the ratio of 1g: 80 ~ 150ml, the layered structure H 4 Nb 6 o 17 Flake particles are added to AgNO with a concentration of 0.05-0.5mol / L 3 After stirring for 12-24 hours in the solution, filter and wash to obtain a precipitate.

[0028] Step 2, in order to make the layered structure H 4 Nb 6 o 17 H in flake particles + After being fully exchanged, the precipitate obtained in step 1 was added to 80-150ml of fresh 0.05-0.5mol / L AgNO at a ratio of 1g:80-150ml 3 After stirring for 12-24 hours in the solution, filter and wash to obtain a precipitate again. After this step is repeated 2 to 4 times (the precipitation obtained in the previous step is used as the reaction material each time), the layered structure Ag is finally obtained after drying. 3 Hb 6 o 17 .

[0029] Step 3, the...

Embodiment 1

[0033] a kind of Ag 2 Nb 4 o 11 A preparation method for nano-textured sheet-like particles, comprising the following steps:

[0034] Step 1: Take 1.0g layered structure H 4 Nb 6 o 17 , added to 80ml of AgNO with a concentration of 0.05mol / L 3 The solution was stirred for 12h, then filtered and washed to obtain a precipitate.

[0035] Step 2: In order to make the layered structure H 4 Nb 6 o 17 H in flake particles + was fully exchanged, and the precipitate obtained in step 1 was added to 80ml of fresh AgNO with a concentration of 0.05mol / L 3 solution, after stirring for 12 hours, filtered, washed, and dried to finally obtain a layered Ag 3 Hb 6 o 17 .

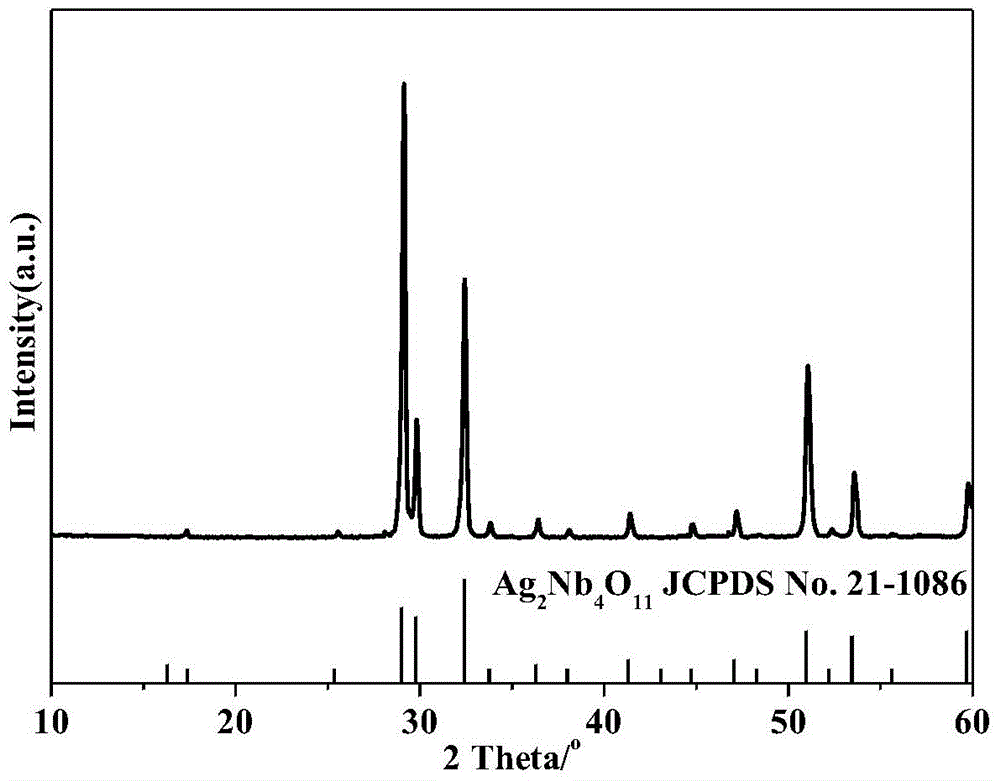

[0036] Step 3: the Ag obtained in step 2 3 Hb 6 o 17 Heat treatment at 400°C for 2h to obtain Ag 2 Nb 4 o 11 Nano-textured flake particles.

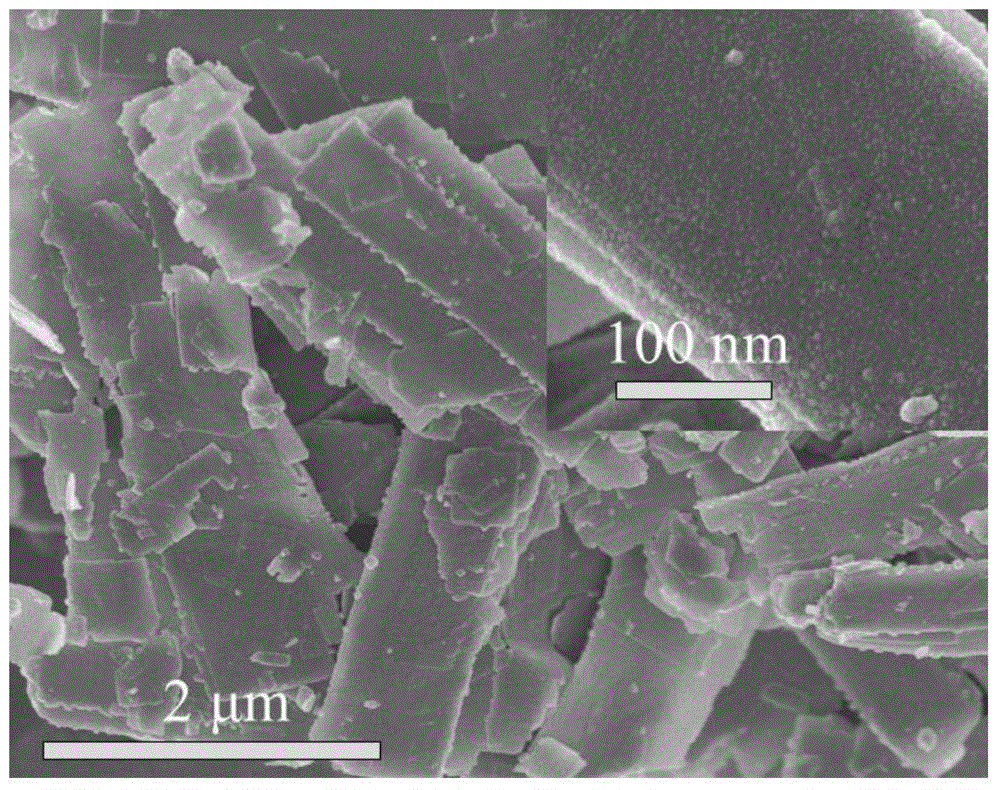

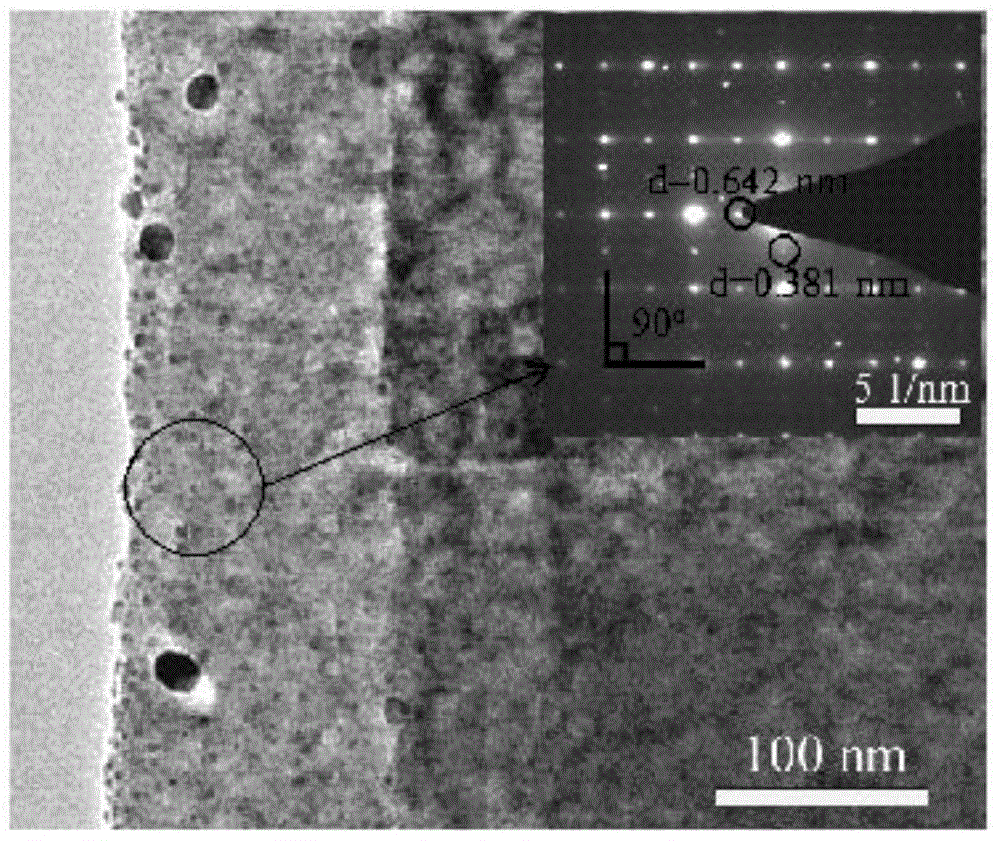

[0037] The Ag obtained in this embodiment 2 Nb 4 o 11 The average length of the nano-textured flake particles is 2 μm, the average width is 1 μm, and the average ...

Embodiment 2

[0039] a kind of Ag 2 Nb 4 o 11 A preparation method for nano-textured sheet-like particles, comprising the following steps:

[0040] Step 1: Take 1.0g layered structure H 4 Nb 6 o 17 , added to 100ml of AgNO with a concentration of 0.4mol / L 3 The solution was stirred for 12h, then filtered and washed to obtain a precipitate.

[0041] Step 2: In order to make the layered structure H 4 Nb 6 o 17 H in flake particles + was fully exchanged, and the precipitate obtained in step 1 was added to 100ml of fresh AgNO with a concentration of 0.4mol / L 3 solution, after stirring for 12h, filtered and washed to obtain a precipitate again. After this step is repeated 2 times (each time, the precipitation obtained in the previous step is used as the reaction material), the layered structure Ag is finally obtained after drying. 3 Hb 6 o 17 .

[0042] Step 3: the Ag obtained in step 2 3 Hb 6 o 17 Heat treatment at 500°C for 4h to obtain Ag 2 Nb 4 o 11 Nano-textured flake p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com