Spatially ordered frame structure ceramic-metal composite material and preparation method thereof

A metal composite material and frame structure technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of unsuitable performance of plastic templates, residual impurities in closed spaces, and easy deformation, and achieve good impact toughness and excellent friction performance. and the effect of heat resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

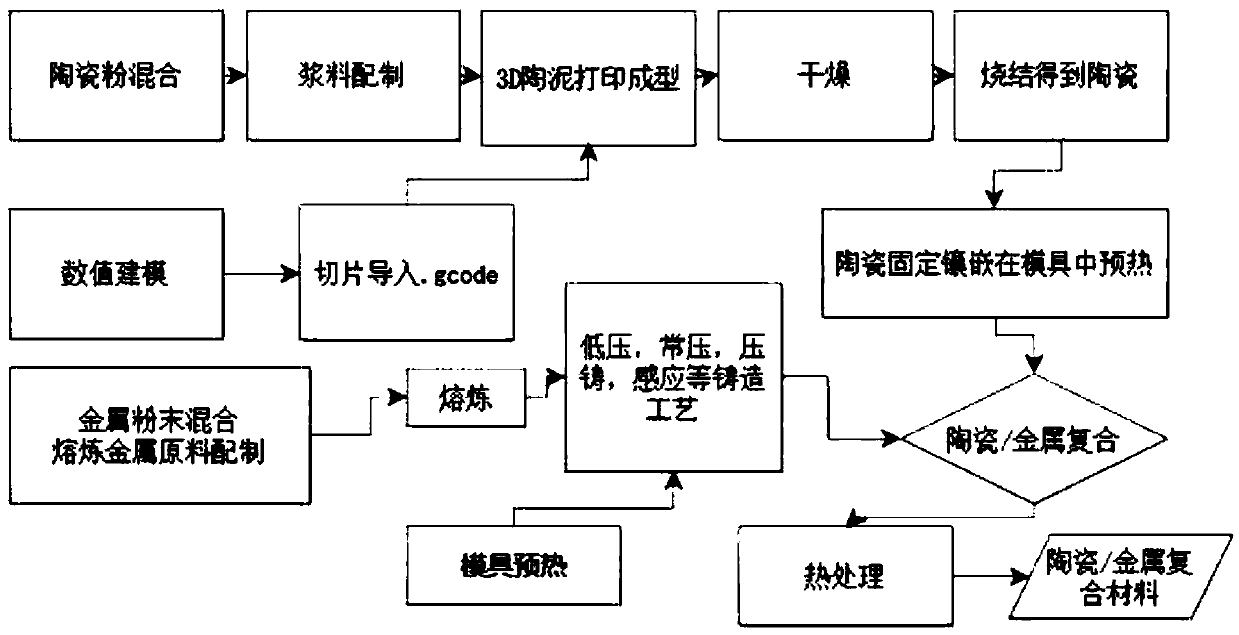

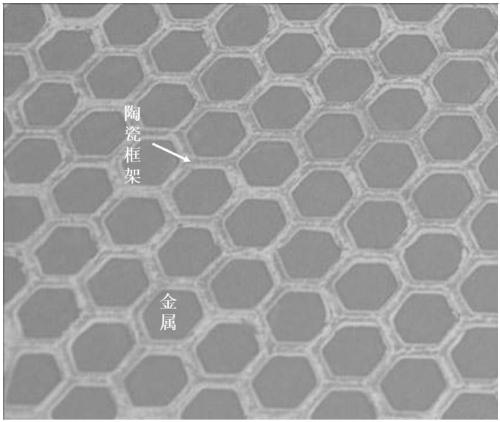

[0043] The invention provides a method for preparing a space-ordered frame structure ceramic-metal composite material, comprising the following steps:

[0044](1) Obtain 3D printing slice data according to the predetermined ceramic molding structure;

[0045] (2) ball milling the ceramic powder, forming aid and liquid medium to obtain a slurry, and performing 3D clay printing on the slurry according to the 3D printing slice data to obtain a ceramic blank;

[0046] (3) drying and sintering the ceramic blank described in step (2) in sequence to obtain a ceramic matrix with a spatially ordered frame structure;

[0047] (4) Carry out film covering treatment to the ceramic substrate described in step (3) using a heat-conducting lubricating material;

[0048] (5) Composite the metal material and the ceramic matrix after film covering treatment by metal casting or powder metallurgy to obtain a ceramic-metal composite material with a spatially ordered frame structure.

[0049] The r...

Embodiment 1

[0074] A method for preparing a spatially ordered frame structure ceramic-metal composite material, specifically comprising the following steps:

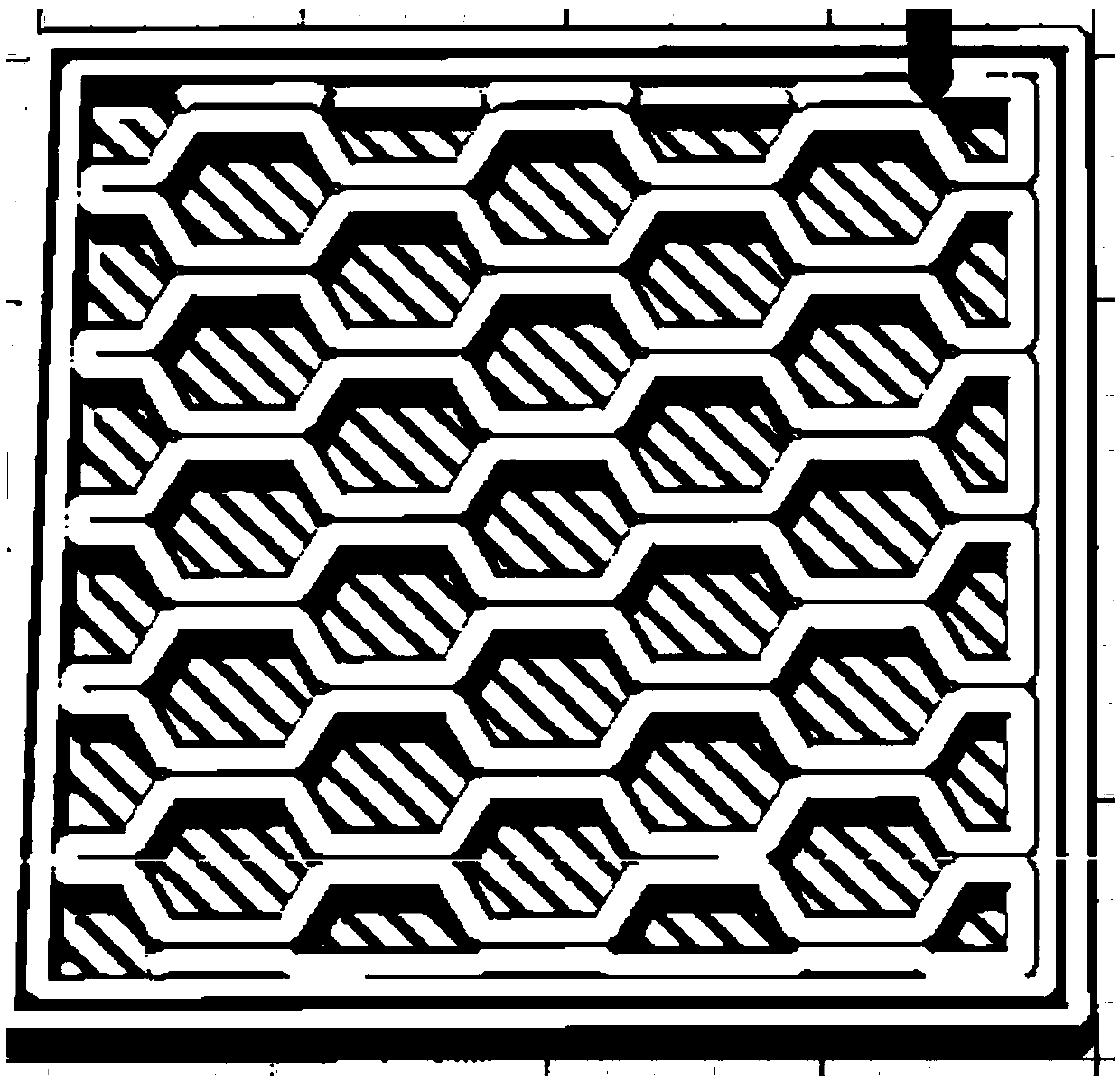

[0075] (1) establish the alumina-kaolin ceramic three-dimensional model of space order frame structure with Solidwork (attached to the present invention figure 2 ). Use Cura to cut the 3D model, save it as a .gcode file, and import it to the 3D printer.

[0076] (2) Calculate the mixed powder of 70% alumina, 25% kaolin, and 5% magnesium oxide as 100%, add 0.5% sodium hexametaphosphate, 8% glycerol, 1.2% carboxymethyl cellulose, and PVA 1%, the defoamer selects 1% of the ceramic slurry defoamer (produced by Defeng Company) of model DF-179 / 8868 / 176 for use, and the hyperdispersant selects 0.5% of model Dolapix CE-64 (produced by German Sima Chemical Industry), The superplasticizer is POLYOX WSRN-80 (produced by American Dow Chemical Company) 0.5% and mixed evenly. After ball milling for 24 hours, a slurry with good thixotropy and f...

Embodiment 2

[0084] A method for preparing a spatially ordered frame structure ceramic-metal composite material, specifically comprising the following steps:

[0085] (1) SiC-Si with spatially ordered frame structure built by UG 3 N 4 Ceramic three-dimensional model (attached to the present invention Figure 4 ). Use Simplify3D to cut the 3D model, save it as a .gcode file, and import it to the 3D printer.

[0086] (2) Refractory material waste (mainly magnesium oxide, chromium oxide) and smelting waste residue (mainly aluminum oxide, silicon oxide, calcium oxide) make up about 80% in total. After crushing, screening and iron removal, mullite, bentonite and titanium oxide powder are added in a total of about 20%. After initial mixing with stirring, the mixed powder obtained by ball milling for 30 hours has a particle size of 0.5 μm. Add sodium polyphosphate 0.2%, tetramethylammonium hydroxide 0.5%, glycerin 5%, carboxymethyl cellulose 1.0%, PVA binder 0.8%, defoamer Z-3290 ceramic slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com