Preparation and application of light, heat-insulating and flame-retardant PIPD nanofiber aerogel

A nanofiber, airgel technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, single-component synthetic polymer rayon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

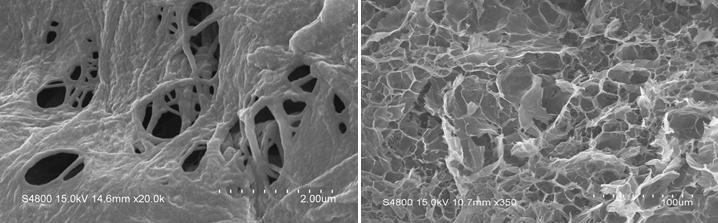

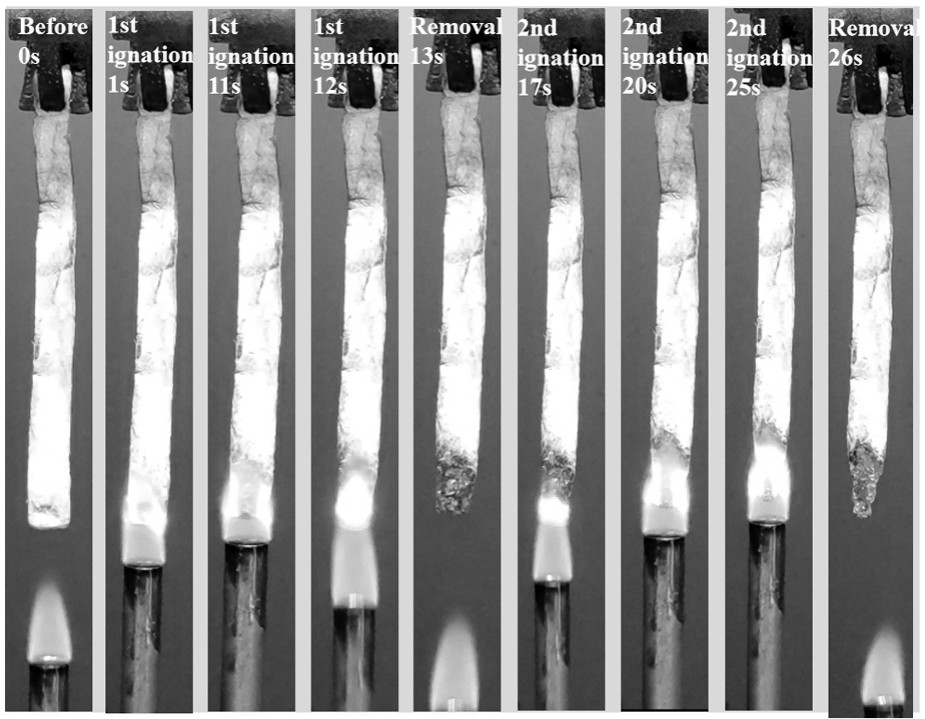

[0020] The invention provides a kind of preparation method of light weight, heat insulation, fire-retardant PIPD nanofiber airgel, comprising the following steps:

[0021] (1) Mix a certain amount of PIPD with mixed acid, and obtain PIPD nanofiber sol after ultrasonic treatment;

[0022] (2) The PIPD nanofiber sol is added with different proportions of proton-removing agents under stirring, and left to stand for a period of time under a constant temperature environment to obtain a stable gel;

[0023] (3) Soak the stable gel in a solvent for solvent exchange, then freeze-dry, and finally process at high temperature under an inert atmosphere to obtain PIPD nanofiber airgel.

[0024] In the present invention, the mass concentration of the PIPD in the mixed acid is 0.1-4wt%, more preferably 0.25-2wt%. The present invention preferably controls the mass concentration of PIPD in the mixed acid within the above-mentioned range, and can obtain uniform and completely dispersed PIPD na...

Embodiment 1

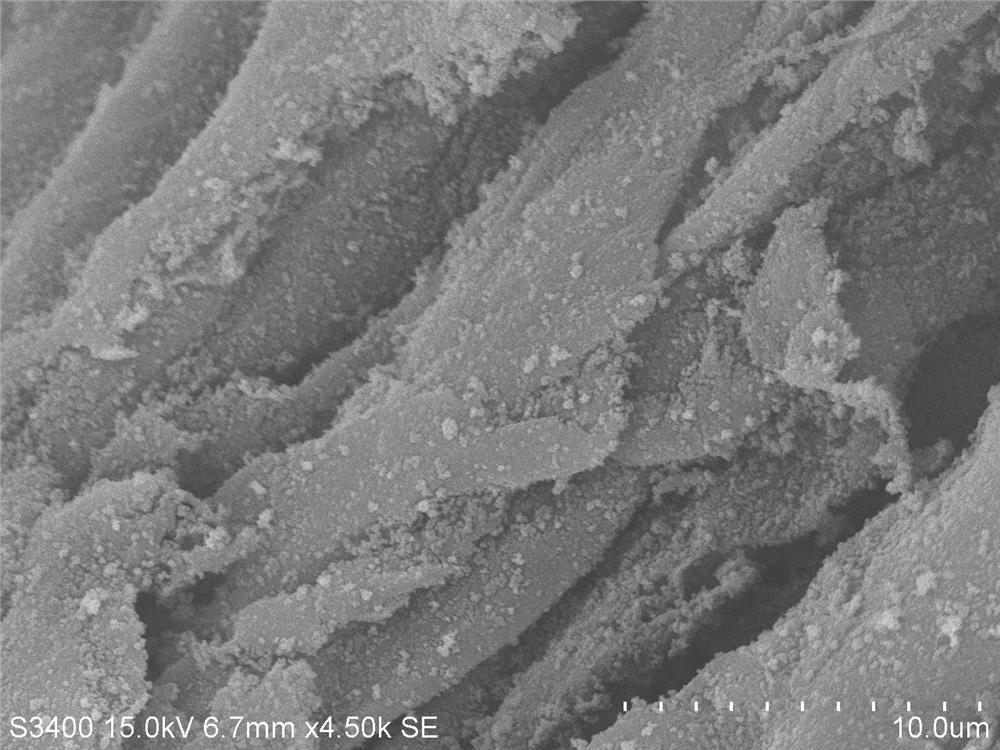

[0034] Weigh 0.1g of clean PIPD (intrinsic viscosity 9.7dL / g) into a 100ml single-necked flask, then add 18.6g of trifluoroacetic acid and 5.4g of methanesulfonic acid, seal it and place it in an ultrasonic cleaner at 35°C for ultrasonication to obtain PIPD Nanofiber sol.

[0035] Weigh 3.5g of methanesulfonic acid, 0.05g of deionized water, and 0.5g of ethyl acetate into a beaker, and stir evenly to obtain a proton-removing agent. Weigh 10g of PIPD nanofiber sol, pour the proton-removing agent into the PIPD nanofiber sol, stir at 1200rpm and pour it into the mold, then add enough deionized water to stabilize the mixed acid in the PIPD nanofiber gel. Replaced, and finally exchanged with tert-butanol solvent to obtain PIPD nanofiber wet gel.

[0036] The PIPD nanofiber wet gel was pre-frozen in a temperature-controlled refrigerator, then freeze-dried, then placed in a tube furnace, heated to 400 °C under a nitrogen atmosphere, and kept at a constant temperature for 30 minutes ...

Embodiment 2

[0039] Weigh 0.05g of clean PIPD (intrinsic viscosity 5.8dL / g) into a 100ml single-necked flask, then add 12g of trifluoroacetic acid, 7g of methanesulfonic acid, 1g of concentrated sulfuric acid, seal and place in an ultrasonic cleaner at 25°C Ultrasound to obtain PIPD nanofiber sol.

[0040] Weigh 2.8g of methanesulfonic acid, 0.13g of deionized water, 0.85g of ethyl acetate, and 0.05g of ethanol in a beaker, and stir evenly to obtain a proton-removing agent. Weigh 10g of PIPD nanofiber sol, pour the proton-removing agent into the PIPD nanofiber sol, stir at 1500rpm and pour it into the mold, then add enough phenol and water (w / w=5:1) to mix The solvent replaces the mixed acid in the PIPD nanofiber stable gel to obtain the PIPD nanofiber wet gel.

[0041] The PIPD nanofiber wet gel was pre-frozen in a temperature-controlled refrigerator, then freeze-dried, then placed in a tube furnace, heated to 350 °C under a nitrogen atmosphere, and kept at a constant temperature for 35 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com