Antimony/terbium-codoped plumbite antimonate luminescent material, and preparation method and application thereof

A luminescent material, lead antimonate technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve problems such as unfavorable preparation of luminescent materials, uncontrollable ratio of phosphate and rare earth elements, insufficient thermal stability, etc. , to achieve good thermal and chemical stability, easy growth orientation, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

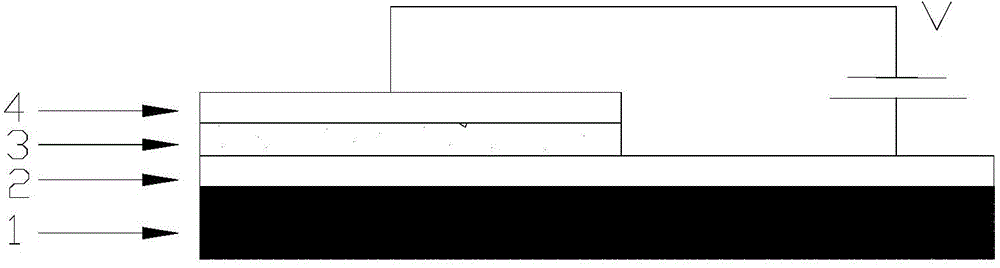

[0038] A method for preparing a thin film electroluminescent device, comprising the steps of:

[0039] (1) First, weigh MgO and PbO respectively according to the molar ratio of 1:3.94:3:0.02:0.01 2 , Sb 2 o 5 , SbO 2 and Tb 4 o 7 powder, and these powders are evenly mixed and sintered at 1250°C to make a ceramic target with a diameter of 50mm and a thickness of 2mm; and then put the prepared ceramic target into the vacuum chamber of the pulse laser deposition coating equipment in vivo;

[0040] (2) Ultrasonic cleaning the glass substrate with ITO transparent conductive film with acetone, absolute ethanol and deionized water respectively, and performing oxygen plasma treatment on it; then put the cleaned ITO glass substrate into the pulse laser deposition coating equipment In the vacuum chamber, and the vacuum degree of the vacuum chamber is pumped to 5.0×10 with a mechanical pump and a molecular pump -4 Pa;

[0041] (3) Adjust the pulse laser deposition and coating pro...

Embodiment 2

[0047] A method for preparing a thin film electroluminescent device, comprising the steps of:

[0048] (1) First, weigh MgO and PbO respectively according to the molar ratio of 1:3.91:3:0.01:0.02 2 , Sb 2 o 5 , SbO 2 and Tb 4 o 7 powder, and these powders are evenly mixed and sintered at 900°C to make a ceramic target with a diameter of 50mm and a thickness of 2mm; and then put the prepared ceramic target into the vacuum chamber of the pulse laser deposition coating equipment in vivo;

[0049] (2) Ultrasonic cleaning the glass substrate with ITO transparent conductive film with acetone, absolute ethanol and deionized water respectively, and performing oxygen plasma treatment on it; then put the cleaned ITO glass substrate into the pulse laser deposition coating equipment In the vacuum chamber, and use a mechanical pump and a molecular pump to pump the vacuum chamber to 1.0×10 -3 Pa;

[0050] (3) Adjust the pulse laser deposition and coating process parameters to prepar...

Embodiment 3

[0054] A method for preparing a thin film electroluminescent device, comprising the steps of:

[0055] (1) First, weigh MgO and PbO respectively according to the molar ratio of 1:3.94:3:0.05:0.0025 2 , Sb 2 o 5 , SbO 2 and Tb 4 o 7 powder, and these powders are evenly mixed and sintered at 1300°C to make a ceramic target with a diameter of 50mm and a thickness of 2mm; then put the prepared ceramic target into the vacuum chamber of the pulse laser deposition coating equipment in vivo;

[0056] (2) Ultrasonic cleaning the glass substrate with ITO transparent conductive film with acetone, absolute ethanol and deionized water respectively, and performing oxygen plasma treatment on it; then put the cleaned ITO glass substrate into the pulse laser deposition coating equipment In the vacuum chamber, and use a mechanical pump and a molecular pump to pump the vacuum chamber to 1.0×10 -5 Pa;

[0057] (3) Adjust the pulse laser deposition and coating process parameters to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com