Cr<3+>-doped zirconium silicate as well as preparation method and application thereof

A zirconium silicate, wet ball milling technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of simple preparation process, wide source, good chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Embodiments of the present application provide a doped Cr 3+ The preparation method of zirconium silicate, comprises the steps:

[0021] (1) Take each raw material by molecular formula stoichiometric ratio, wherein, said raw material comprises ZrO 2 , SiO 2 and Cr 2 o 3 ;

[0022] (2) Add the raw materials in step (1) to Li 2 CO 3 Finally, fully mix evenly, put the mixture in deionized water for wet ball milling, and mix evenly again to obtain the mixture;

[0023] (3) The mixture is dried in an oven, and the dried powder is fully ground in an agate jar;

[0024] (4) After grinding, the powder is put into a mold for tabletting;

[0025] (5) Put the powder obtained in the above step (4) into a high-temperature muffle furnace, and calcinate in an air atmosphere to obtain a zirconium silicate sample.

[0026] Optionally, the raw materials used in step (1) also include Li 2 CO 3 , Li in the step (1) 2 CO 3 Occupies 0.1 wt% of the total raw material weight.

[...

Embodiment 1

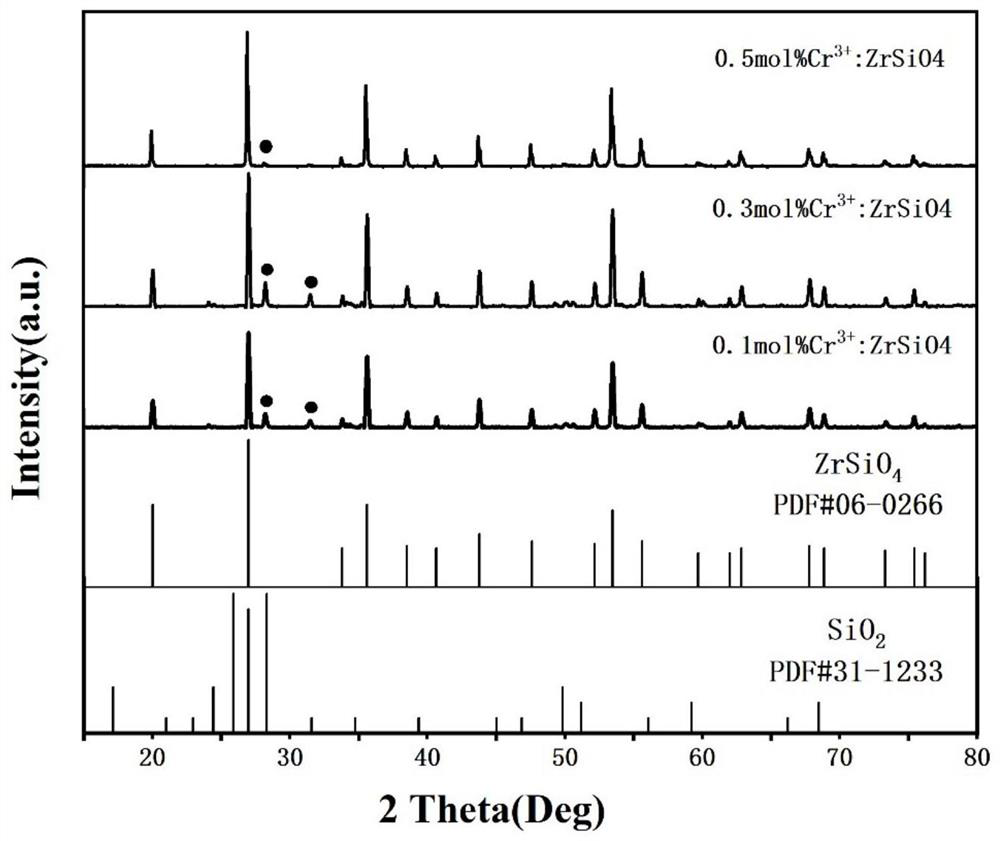

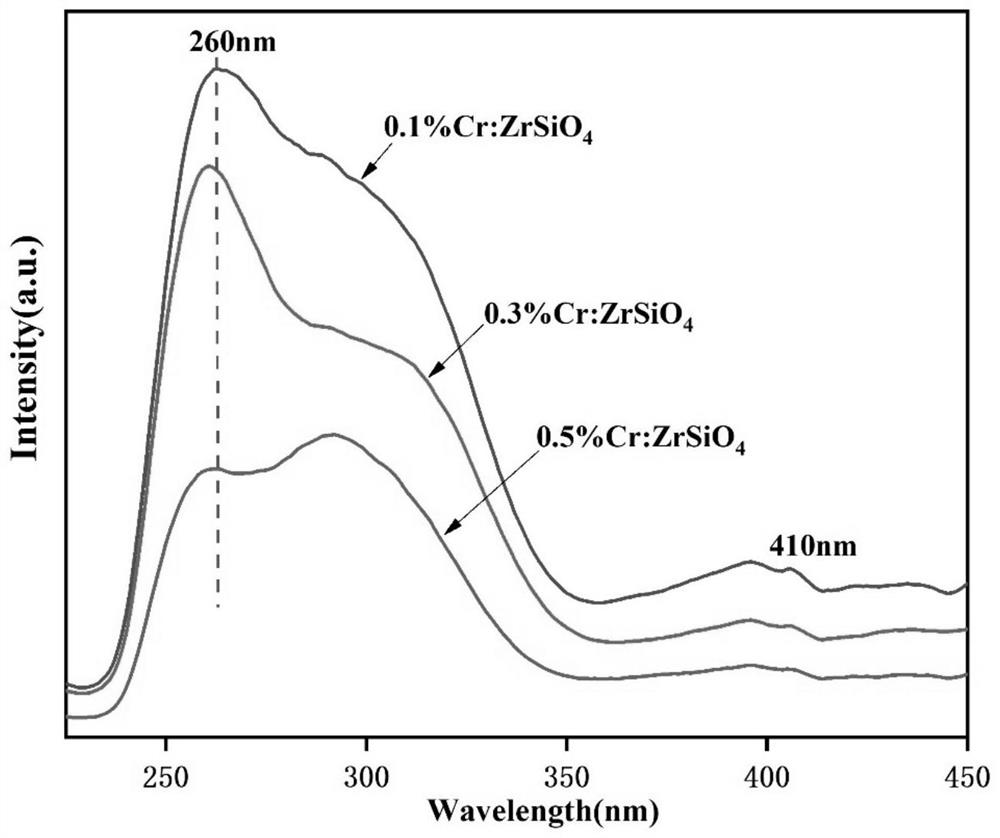

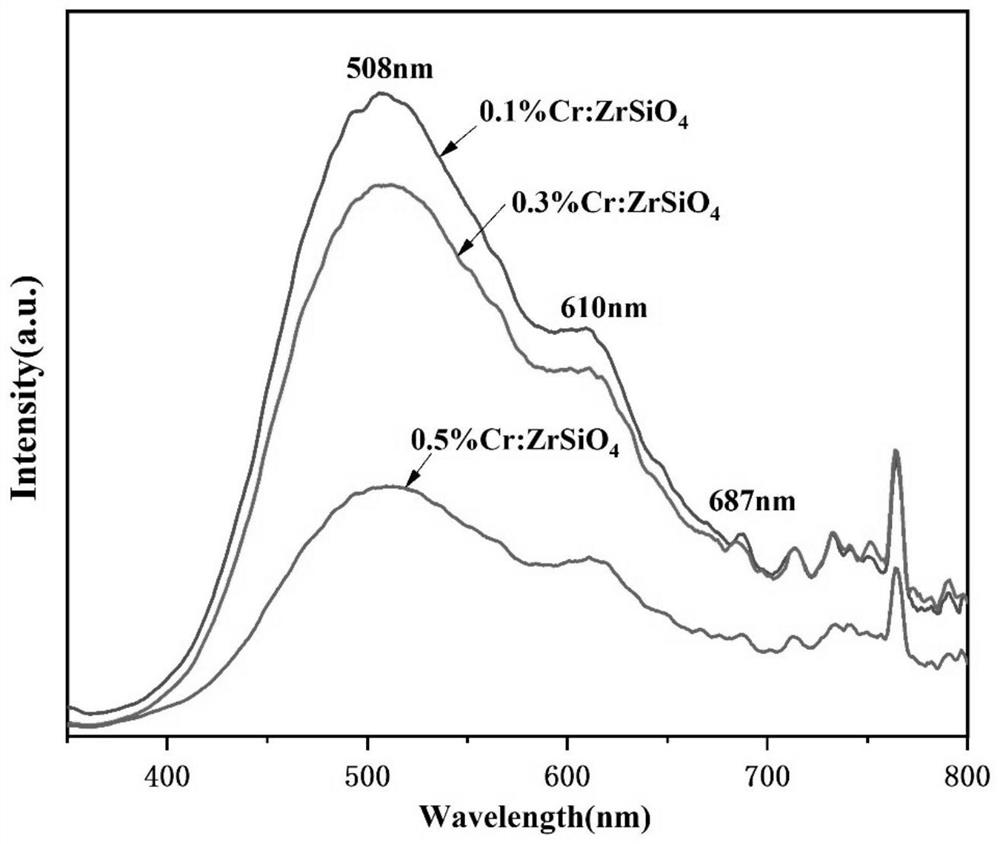

[0038] Preparation of 0.1mol% Cr 3+ : ZrSiO4

[0039] (1) ZrO 2 , SiO 2 , Cr 2 o 3 As raw materials, each raw material is weighed according to the molecular formula stoichiometric ratio.

[0040] (2) Add the raw materials in the above step (1) to Li 2 CO 3 Afterwards, fully mix evenly, put the mixture in deionized water and wet ball mill, and mix evenly again to obtain the mixture.

[0041] (3) The mixture is dried in an oven, and the dried powder is fully ground evenly in an agate jar.

[0042] (4) After grinding, put the powder into a mold for tableting.

[0043] (5) Put the powder obtained in the above step (4) into a high-temperature muffle furnace, and calcinate in an air atmosphere to obtain a zirconium silicate sample.

[0044] Preferably, the raw material used in step (1) is ZrO 2 , SiO 2 , Cr 2 o 3 , Li 2 CO 3 , the mineralizer Li 2 CO 3 The total amount is 0.1 wt%. Weigh 0.01 g of dichromium trioxide, 3.32 g of silicon dioxide, 6.67 g of zirconia, a...

Embodiment 2

[0053] Preparation of 0.3mol% Cr 3+ : ZrSiO 4

[0054] (1) ZrO 2 , SiO 2 , Cr 2 o 3 As raw materials, each raw material is weighed according to the molecular formula stoichiometric ratio.

[0055] (2) Add the raw materials in the above step (1) to Li 2 CO 3 Afterwards, fully mix evenly, put the mixture in deionized water and wet ball mill, and mix evenly again to obtain the mixture.

[0056] (3) The mixture is dried in an oven, and the dried powder is fully ground evenly in an agate jar.

[0057] (4) After grinding, put the powder into a mold for tableting.

[0058] (5) Put the powder obtained in the above step (4) into a high-temperature muffle furnace, and calcinate in an air atmosphere to obtain a zirconium silicate sample.

[0059] Preferably, the raw material used in step (1) is ZrO 2 , SiO 2 , Cr 2 o 3 , Li 2 CO 3 , the mineralizer Li 2 CO 3 The total amount is 0.1 wt%. Weigh 0.03 g of dichromium trioxide, 3.31 g of silicon dioxide, 6.66 g of zirconia,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com