Nano graphene material and preparation method and application thereof

A nano-graphene, inert gas technology, applied in nanotechnology, chemical instruments and methods, other chemical processes, etc., can solve the problems of long reaction route, difficult to obtain raw materials, harsh conditions, etc., to achieve strong green light absorption ability, good Thermal and chemical stability, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

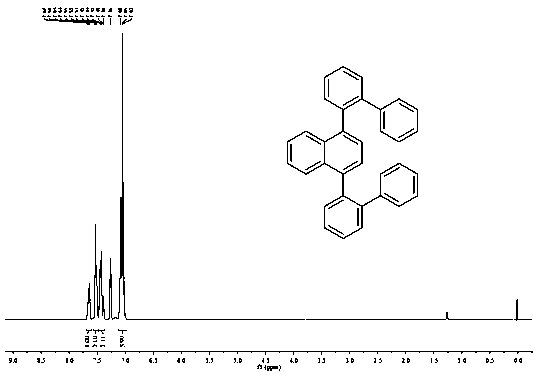

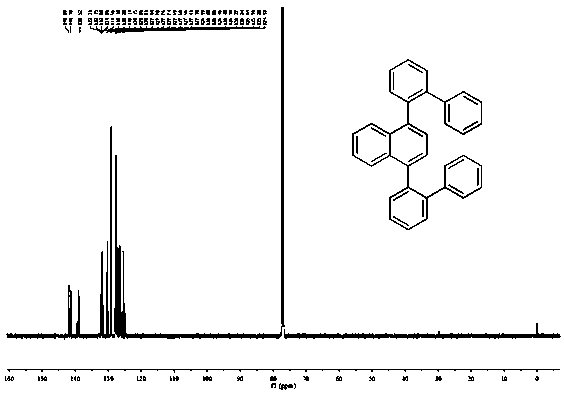

[0038] Add 12 mmol of 2-phenylphenylboronic acid, 5 mmol of 1,4-dibromonaphthalene, 24 mmol of potassium carbonate, 15 mL of ethanol, and 15 mL of deionized water into the sealed tube in sequence, and inert gas (argon) for 10 min Then add 0.3 g of palladium catalyst (tetrakis(triphenylphosphine) palladium, 10%), and after passing inert gas for 5 min, seal the sealed tube and place it in an oil bath at 80-90 °C for 45-50 h.

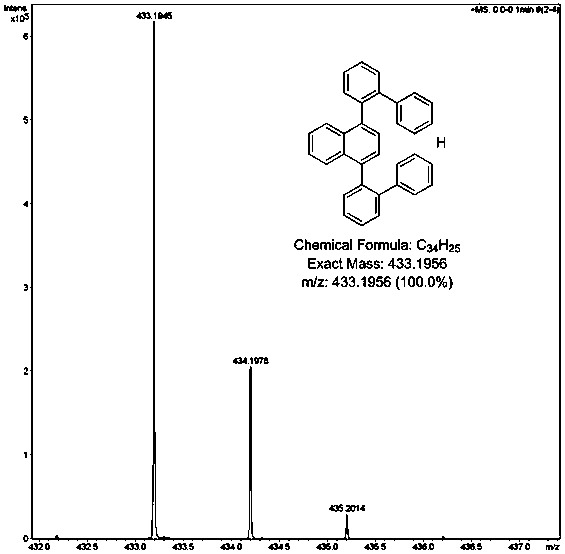

[0039] The reaction product was extracted with ethyl acetate as the extractant, the organic layer was dried, and petroleum ether (60-90 °C) was used as the eluent to separate white solid intermediate 1 by silica gel column chromatography with a yield of 90 %; Structural characterization of Intermediate 1: Melting range 141-143 ℃; HRMS (ESI) m / z: theoretical (C 34 h 24 +H) 433.1956, Literature (C 34 h 24 +H) 433.1951.

Embodiment 2

[0041] Add 10 mmol of 2-phenylphenylboronic acid, 6 mmol of 1,4-dibromonaphthalene, 48 mmol of potassium carbonate, 30 mL of organic solvent xylene, and 30 mL of deionized water into the sealed tube in sequence, and inert gas (argon ) 10 min later, 0.3 g of palladium catalyst (palladium chloride, 10%) was added, and after passing inert gas for 5 min, the sealed tube was sealed and placed in an oil bath at 80-90 °C for 45-50 h.

[0042] The reaction product was extracted with ethyl acetate as the extractant, the organic layer was dried, and petroleum ether (60-90 °C) was used as the eluent to separate white solid intermediate 2 by silica gel column chromatography with a yield of 89 %; Structural characterization of Intermediate 2: Melting range 141-143 ℃; HRMS (ESI) m / z: theoretical (C 34 h 24 +H) 433.1956, Literature (C 34 h 24 +H) 433.1951.

Embodiment 3

[0044]11 mmol 2-phenylphenylboronic acid, 5.5 mmol 1,4-dibromonaphthalene, 30 mmol potassium carbonate, 20 mL organic solvent (a mixed solvent of tetrahydrofuran and water at a volume ratio of 4:1), and 20 mL deionized water were sequentially Put it into a sealed tube, add 0.3 g palladium catalyst (palladium acetate, 10%) after passing inert gas (argon) for 10 min, seal the sealed tube and place it at 80~90 °C after passing inert gas for 5 min React in an oil bath environment for 45-50 h.

[0045] The reaction product was extracted with ethyl acetate as the extractant, the organic layer was dried, and petroleum ether (60-90 °C) was used as the eluent to separate white solid intermediate 3 by silica gel column chromatography with a yield of 92 %; Structural characterization of intermediate 1: its melting range is measured at 141-143°C; HRMS (ESI) m / z: theoretical (C 34 h 24 +H) 433.1956, Literature (C 34 h 24 +H) 433.1951.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com