Glass microfiber cotton and filter paper

A technology of glass microfiber cotton and filter paper, which is applied in filter paper, fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problem of increased glass microfiber cotton ball content, acid resistance soaking weight loss, strength Increase the loss rate and other problems, to achieve the effect of long service life, good chemical stability and thermal stability, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a glass microfiber wool and filter paper according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

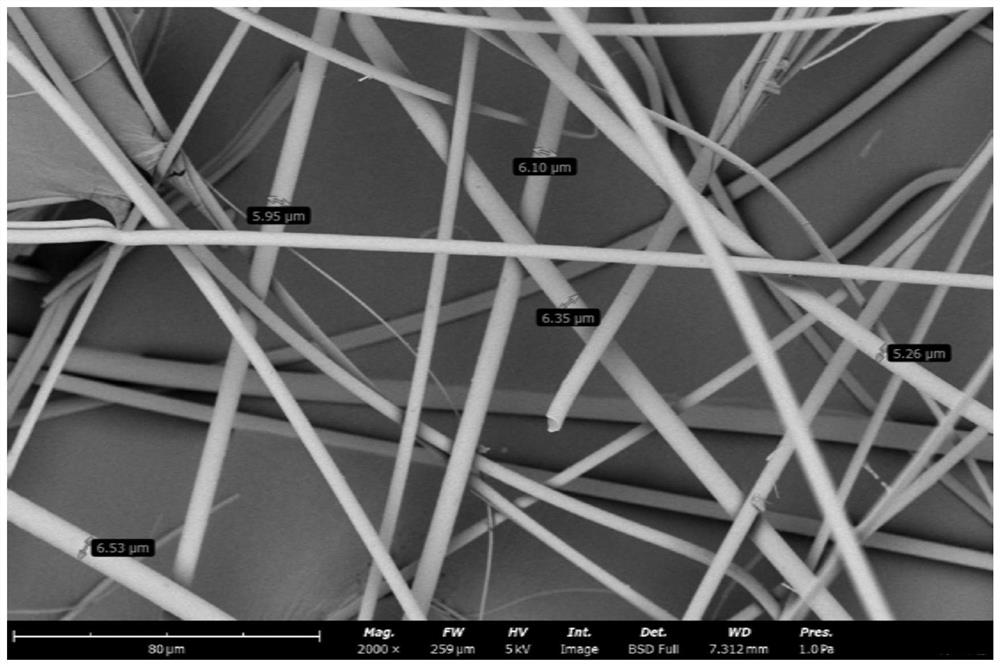

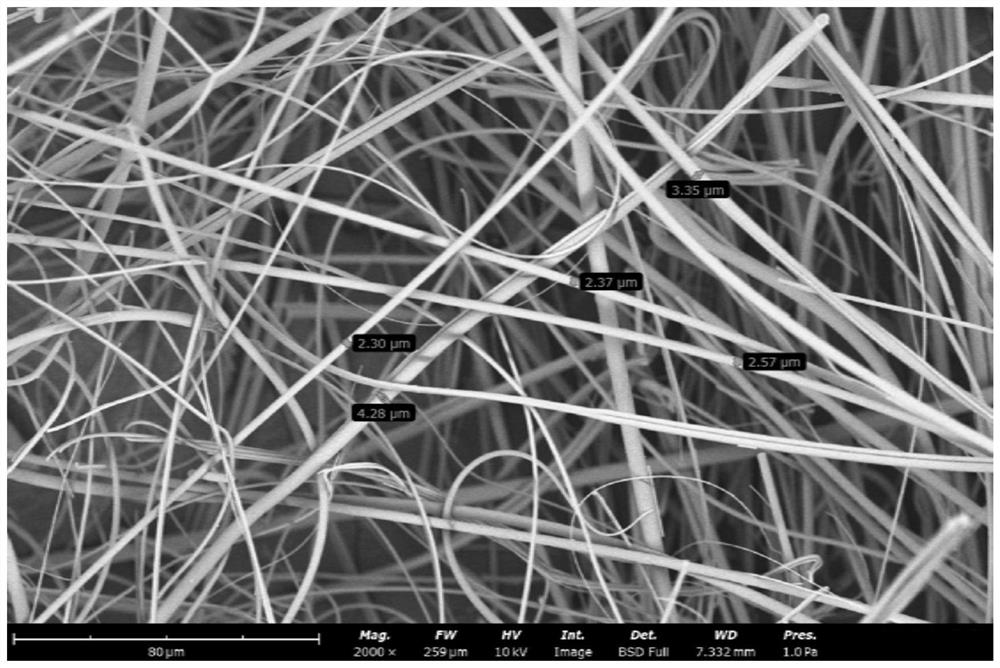

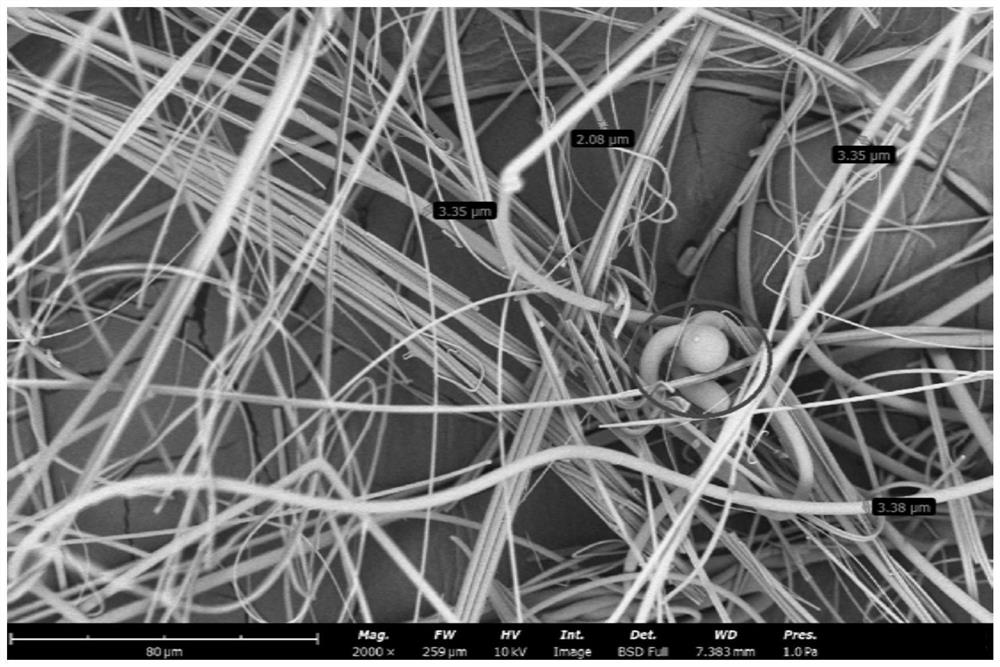

[0022] Specifically, in order to make a certain performance of glass microfiber wool meet the requirements, people will continue to seek to optimize this performance to achieve the optimal value. At this time, while pursuing this performance, they often ignore the impact on other properties. The overall performance of glass microfiber wool is affected. For example, in order to improve the tensile strength of glass microfiber wool, it is often achieved by adjusting the content of glass components and reducing the standard deviation of fiber distribution, but it often leads to the content of slag in glass microfiber wool. Improvement, acid immersion weight loss increase, and may affect the increase in strength loss rate after irradiation, and these are not what we want. Therefore, peop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com