Method for preparing ultrafine alumina powder with vertical faces

A technology of alumina ultra-fine powder and aluminum hydroxide, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem of the preparation process of alumina powder that reports are vertical, cannot be applied, and has no regulation. Product morphology and other problems, to achieve the effect of easy control of microstructure, consistent product morphology, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A method for preparing aluminum oxide superfine powder with vertical faces of the present invention, comprising the following steps:

[0032] (1) Select the sodium aluminate solution used as raw material for the seed fraction obtained after processing diaspore or boehmite by the Bayer process (Na in this sodium aluminate solution 2 o K (Caustic alkali)=162g / L, Al 2 o 3 =190.2g / L, Na 2 Oc=5g / L, Na 2 Os=0g / L, caustic ratio α K = 1.4);

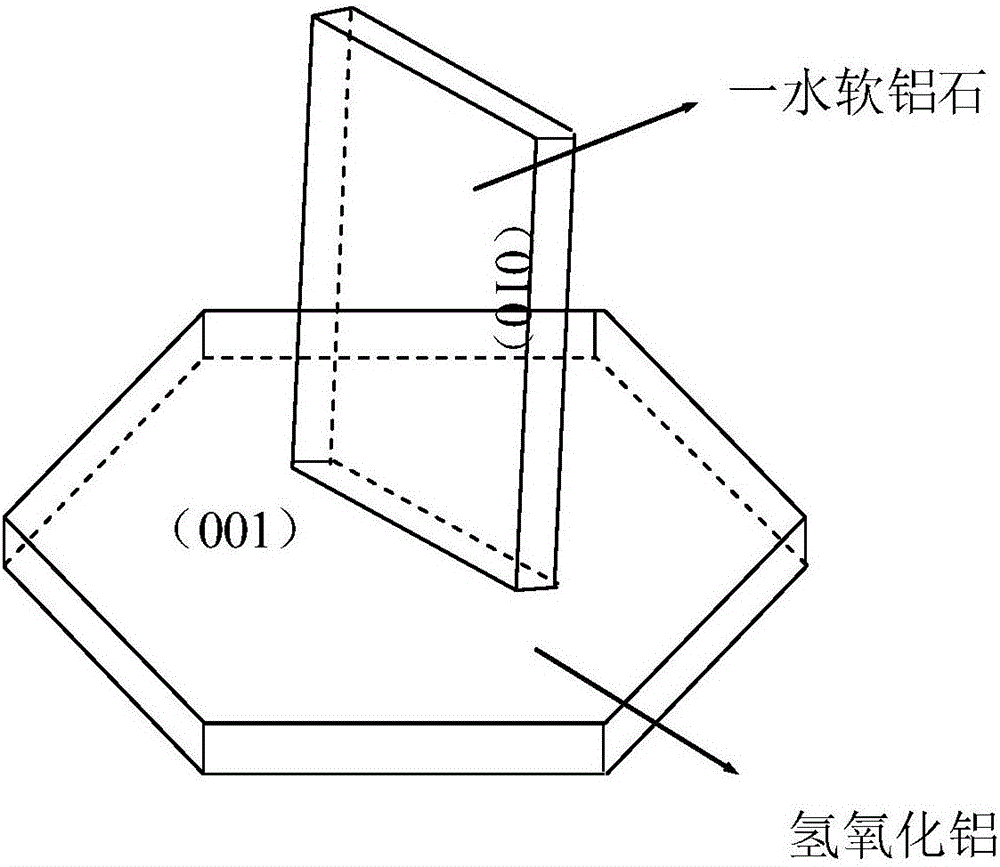

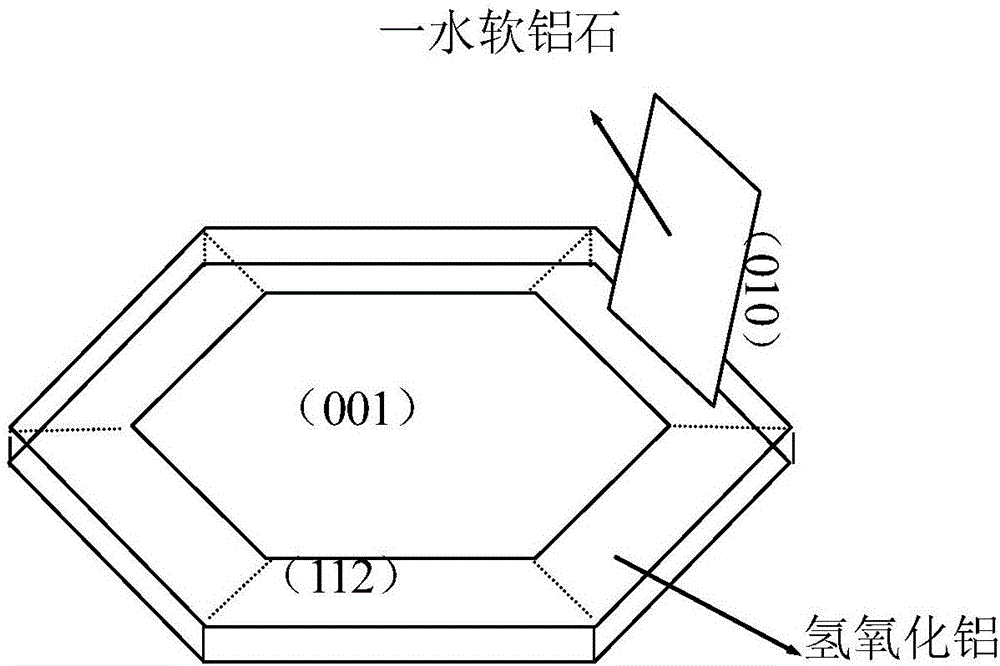

[0033] (2) Take 1000mL of the above sodium aluminate solution, add 500g of flaky aluminum hydroxide (gibbsite type) with an average particle size of 1.7μm, and then react at 140°C for 5h under strong stirring conditions to precipitate a flaky An alumina hydrate dual-phase precursor whose boehmite (010) plane is perpendicular or approximately perpendicular to the flake-shaped gibbsite (001) or (112) plane;

[0034] (3) Calcining the dual-phase precursor obtained in step (2) at 650°C for 2 hours to obtain alumina powder with a special ...

Embodiment 2

[0036] A method for preparing aluminum oxide superfine powder with vertical faces of the present invention, comprising the following steps:

[0037] (1) Take 1000mL sodium aluminate solution (control Na in sodium aluminate solution 2 o K =50g / L, Al 2 o 3 =20.6g / L, Na 2 Oc=0g / L, Na 2 Os=5g / L, caustic ratio α K = 4.0);

[0038] (2) Add 100 g of flake aluminum hydroxide (gibbsite type) with an average particle size of 0.7 μm in the above-mentioned sodium aluminate solution as a seed crystal, and then add 100 ppm polyethylene glycol (molecular weight 6000) for seeding After 3 hours of seeding, the resulting slurry was filtered, washed with hot water, and dried to obtain alumina with flaky boehmite perpendicular or approximately perpendicular to the flaky gibbsite. Hydrate dual-phase precursor; the seed separation mother liquor obtained after filtration is returned to the production system of dissolving aluminum hydroxide or alumina;

[0039] (3) Calcinate the precursor obt...

Embodiment 3

[0041] A method for preparing aluminum oxide superfine powder with vertical faces of the present invention, comprising the following steps:

[0042] (1) Take 1000 mL of sodium aluminate solution, and control the Na in the sodium aluminate solution 2 o K =100g / L, Al 2 o 3 =117.5g / L, Na 2 Oc=15g / L, Na 2 Os=0g / L, caustic ratio α K = 1.4;

[0043] (2) Add 300 g of flaky aluminum hydroxide (gibbsite type) with an average particle size of 1.5 μm in the above-mentioned 1000 mL sodium aluminate solution as a seed crystal, and then add 10 ppm polyethylene glycol (molecular weight 20000) for seeding The temperature of the seed separation process is controlled to be 130°C. After the seed separation is decomposed for 3 hours, the obtained slurry is filtered, washed with hot water, and dried to obtain the flaky boehmite perpendicular or approximately perpendicular to the flaky gibbsite. Alumina hydrate dual-phase precursor; the seed separation mother liquor obtained after filtration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com